6

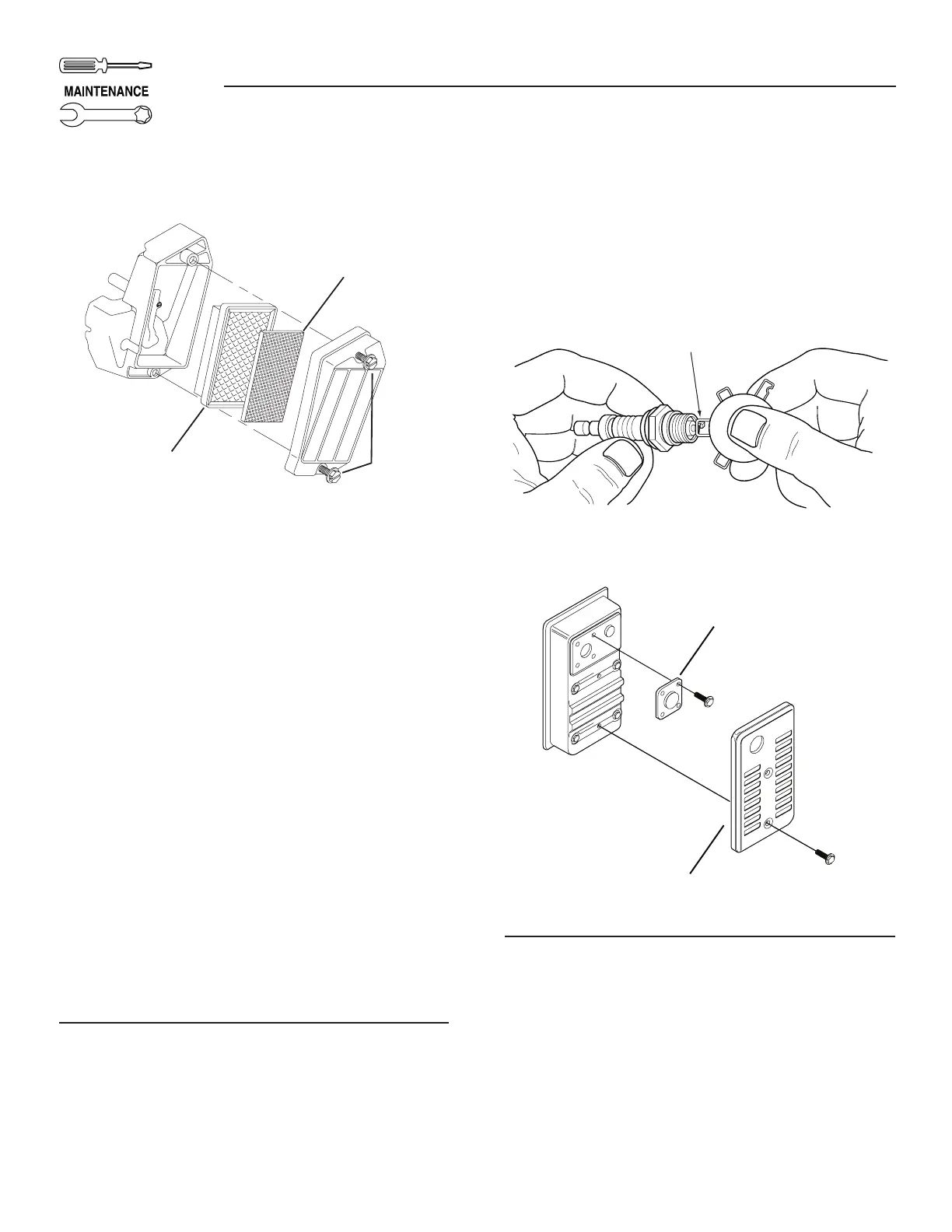

Figure 8 - Air Cleaner Components

PAPER

FILTER

FOAM

PRE-FILTER

COVER

SCREWS

3. To clean or replace the foam pre-filter:

A. Wash the pre-filter in soapy water.

B. Squeeze the pre-filter dry with a clean cloth.

DO NOT TWIST.

NOTE:

If the filter is too dirty, replace it with a new

one. Dispose of the old filter properly.

C. Apply enough clean engine oil to saturate the

pre-filter.

D. Wrap the pre-filter in a clean dry cloth and

squeeze out the excess oil. DO NOT TWIST.

Set the pre-filter aside.

4. To clean or replace the paper air filter:

A. Clean the air filter by tapping it gently on a

solid surface.

NOTE:

If the filter is too dirty, replace it with a new

one. Dispose of the old filter properly.

5. Clean the air cleaner cover.

6. Insert the pre-filter into the cover, then the paper

air filter (see Figure 8).

7. Reinstall the air cleaner cover and tighten the two

(2) screws (see Figure 8).

REPLACING THE SPARK PLUG

Replace spark plug with Generac P/N 0E7585. The

correct air gap is 0.76mm (0.030 in.). Replace the

plug every 100 hours of operation or once each year,

whichever comes first. This will help the engine to

start easier and run better.

1. Stop the engine and pull the spark plug wire off of

the spark plug.

2. Clean around the spark plug and remove it from

the cylinder head.

3. Set the spark plug gap (Figure 9) to 0.76mm

(0.030 in.). Install a correctly gapped spark plug

into the cylinder head.

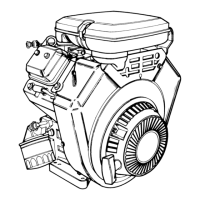

Figure 9 - Setting Spark Plug Gap

SET PLUG GAP AT 0.76 mm

(0.030 inch)

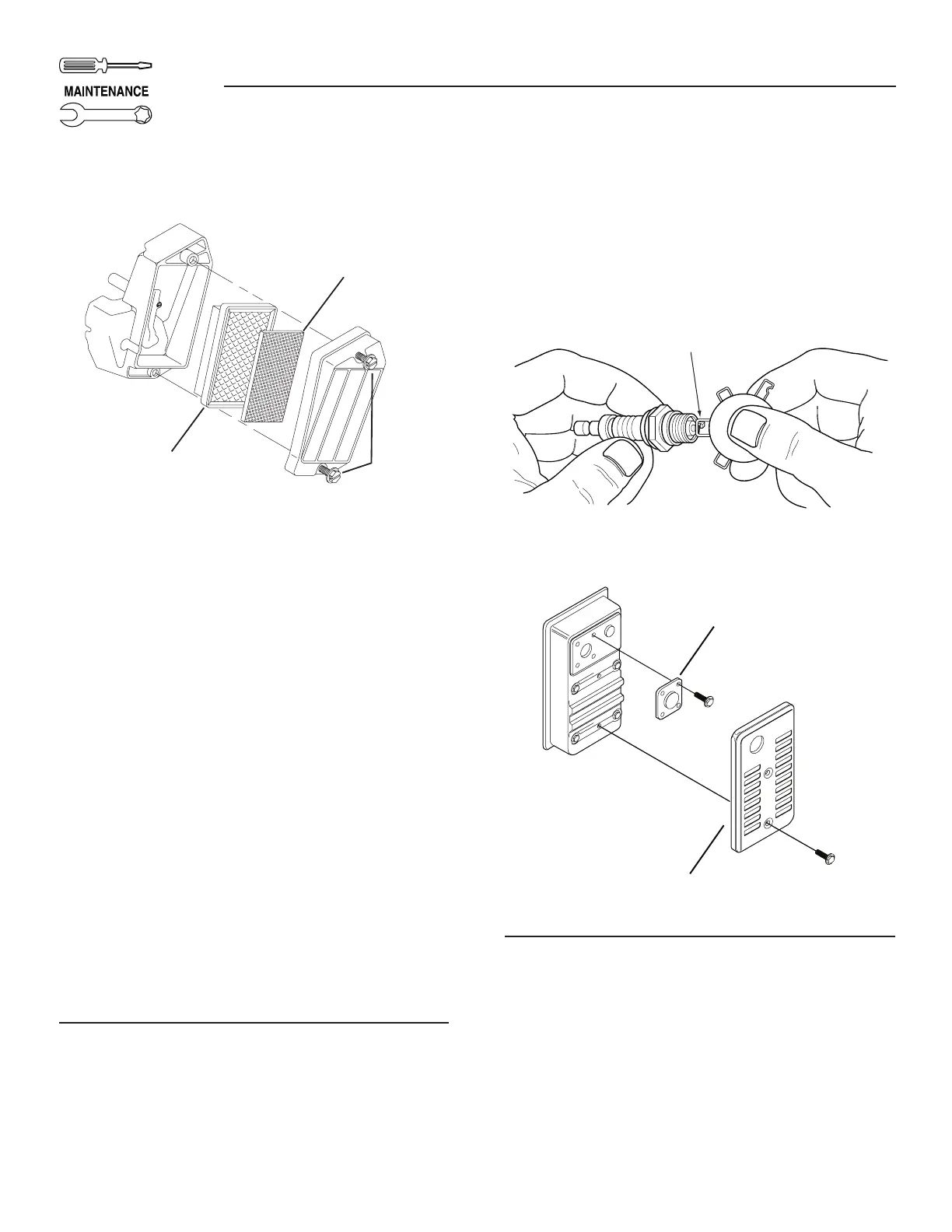

Figure 10 - Spark Arrestor

SPARK ARRESTOR

SCREEN P/N 083083

HEAT SHIELD

CLEANING THE SPARK ARRESTOR SCREEN

The engine exhaust muffler may be equipped with a

spark arrestor screen. Inspect and clean the screen

every 100 hours of operation or once each year,

whichever comes first.

NOTE:

If using the engine on any forest-covered,

brush-covered or grass-covered unimproved

land, it must have a spark arrestor. The spark

arrestor must be maintained in good condition

by the owner/operator.

Section 3 — Maintenance

GSH-220 Engine

Loading...

Loading...