Section 1 AC Diagnostic Tests

Diagnostic Repair Manual 15

Results

1. If unit is overloaded, reduce load.

2. If load is within limits but frequency and voltage still

drop excessively, refer to flow chart.

Overloading a generator in excess of its rated wattage

capacity can result in damage to the generator and to

connected electrical devices. Observe the following to

prevent overloading unit:

• Add up total wattage of all electrical devices to be

connected at one time. This total should NOT be

greater than the generator's wattage capacity.

• The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can be found on a data label or decal

affixed to the device.

• If the appliance, tool or motor does not give

wattage, multiply volts times ampere rating to

determine watts (volts x amps = watts).

• Some electric motors, such as induction types,

require about three times more watts of power for

starting than for running. This surge of power lasts

only a few seconds when starting such motors.

Be sure to allow for high starting wattage when selecting

electrical devices to connect to the generator:

1. Calculate watts needed to start the largest motor.

2. Add to that figure the running watts of all other

connected loads.

Test 12 – Adjust Voltage Regulator

NOTE: Always use the unit specific schematics and

wiring diagrams for brush orientation.

Procedure

1. Remove cover from end of alternator assembly.

2. Remove two screws holding down the voltage

regulator (AVR); refer to Figure 2-3 in Section 1 for

identification.

3. Leave AVR connected to stator and brushes.

4. Set DMM to measure AC voltage.

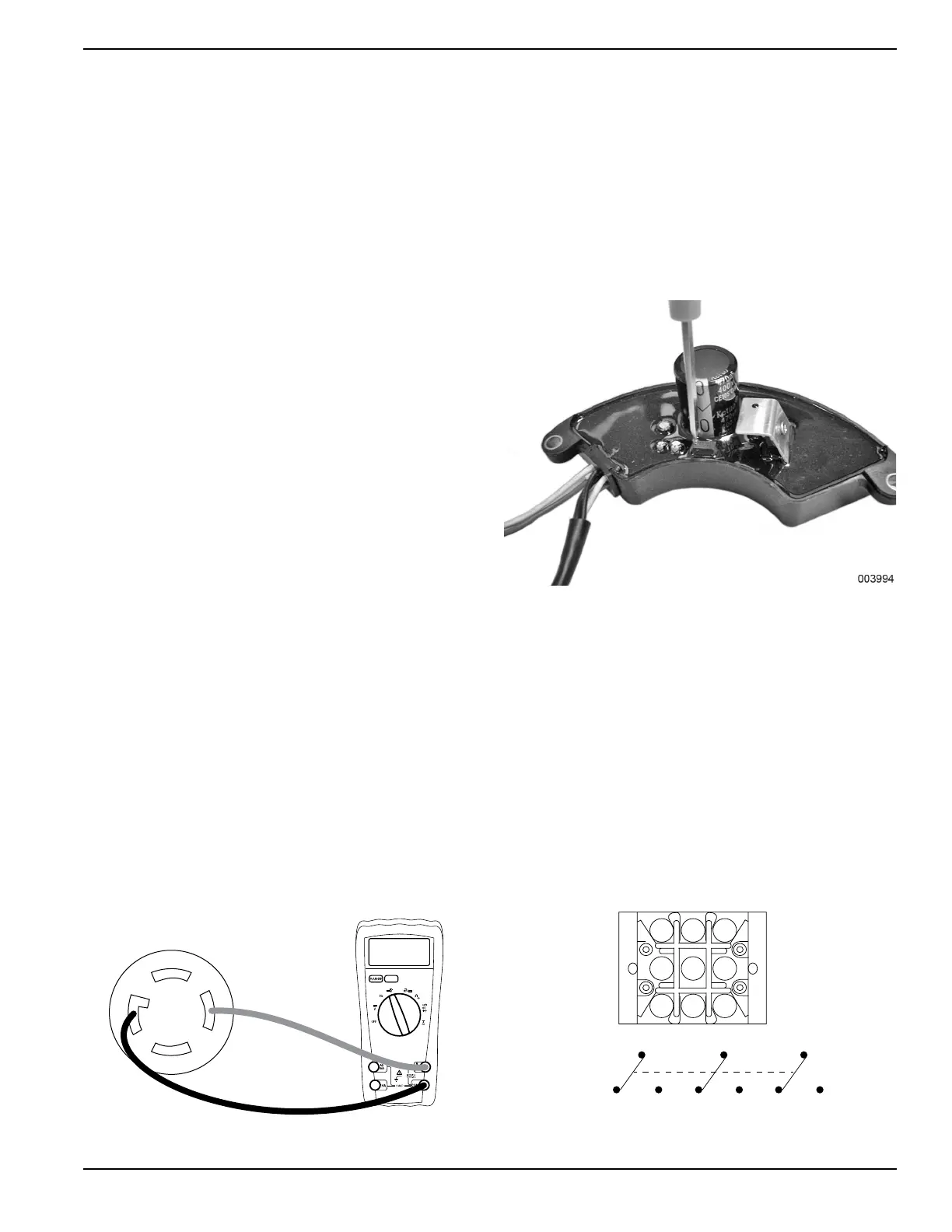

5. See Figure 3-9. Connect DMM across a 240 VAC

receptacle.

Figure 3-9. DMM Test Leads Connected to a 240 VAC

Receptacle

6. Verify all material is clear of the alternator before

proceeding.

7. Set START-STOP-RUN switch to START.

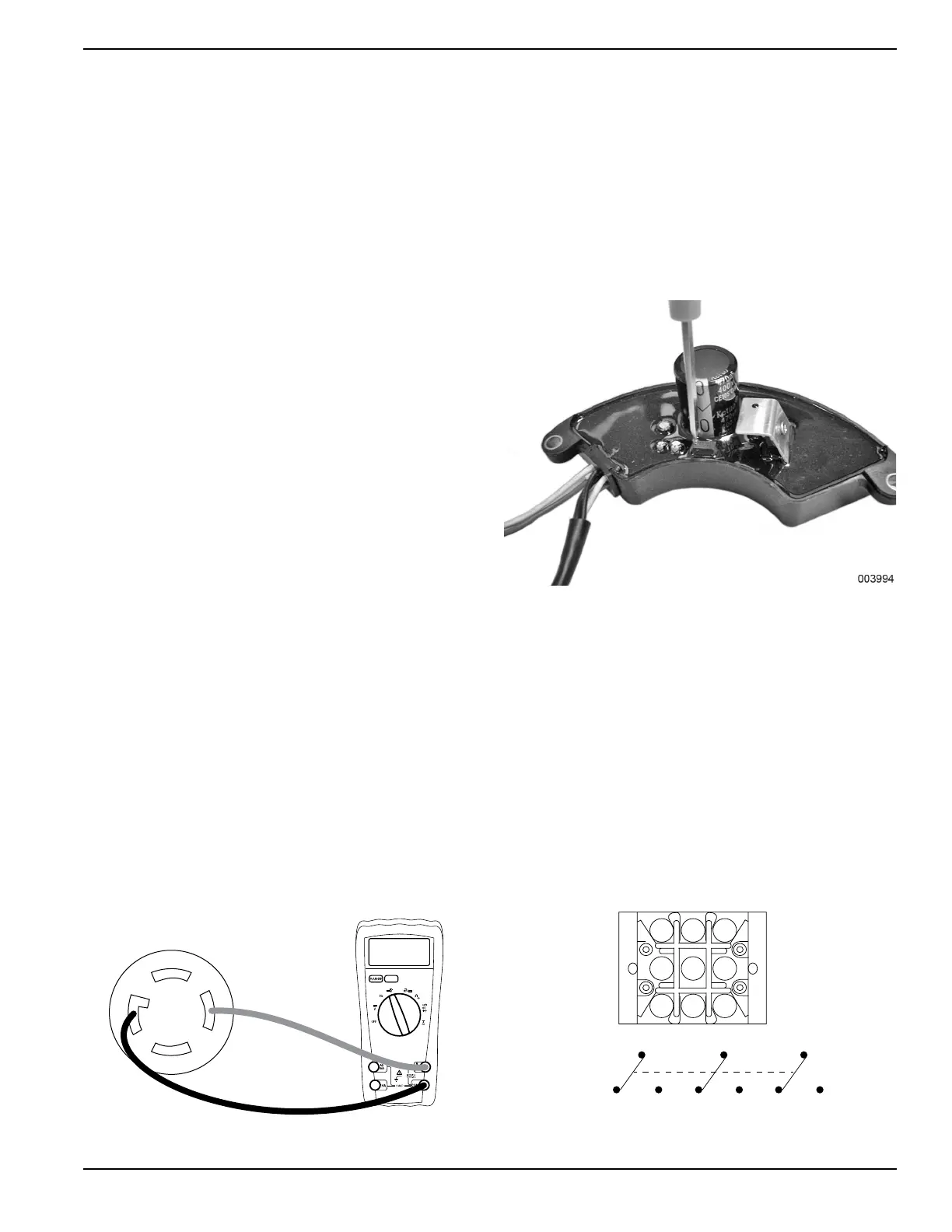

8. See Figure 3-10 for location of adjustment screw.

9. Adjusting screw clockwise will increase voltage,

adjusting counterclockwise will lower voltage.

Results

1. If there is no change in voltage while adjusting,

refer to flow chart.

2. If voltage is correct, stop testing.

Figure 3-10. Voltage Regulator Adjustment Screw

Test 13 – Voltage Changeover Switch

120/240 Position

The voltage change over switch allows the generator to

produce full rated power in the 120 VAC position. The

switch must never be switched while the generator is

running.

1. Remove all the wiring from the voltage change

over switch.

2. Set DMM to read Ohms and zero out the meter.

3. Place the switch in the 120 VAC position and use

the switch schematic and number position to

perform the following tests.

Figure 3-11. Voltage Changeover Switch

3 2 1

6 5 4

9 8 7

7

9461

25 8(COM)

3

3PDT

Loading...

Loading...