12 309043

Maintenance and Service

CAUTION

Protect the internal drive parts of this sprayer from water.

Openings in the shroud allow for air cooling of the mechanical

parts and electronics inside. If water gets into these openings,

the sprayer could malfunction or be permanently damaged.

Caring for Sprayer

Keep the sprayer and all accessories clean and in good

working order. To avoid overheating of motor, keep vent

holes in shroud clear for air flow. Do not cover the

sprayer while spraying.

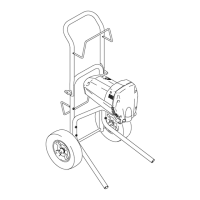

InstaClean Fluid Filter

The InstaClean fluid filter (E) self cleans during pressure

relief. Some embedded particles may require manual

cleaning. Remove pump fluid outlet fitting (D) to remove

and check InstaClean filter. Replace if damaged.

E

D

9570A

Gun Fluid Filter

Clean the gun fluid filter with compatible solvent and a

brush every time you flush the system. Replace when

damaged.

SG1

SG2 / SG3

filter

9561A

9562A

filter

Paint Hoses

Check hose for damage every time you spray. Do not

attempt to repair hose if hose jacket or fittings are

damaged. Do not use hoses shorter than 25 ft (7.6 m).

Tips

Always clean tips with compatible solvent and a brush

after spraying.

Tips may require replacement after spraying 15 gallons

(57 liters), or they may last through 60 gallons (227

liters), depending on the abrasiveness of the paint. Do

not spray with a worn tip.

Pump Check Valves

Inadequate flushing of paint can

cause the inlet valve check balls to

stick to the seats. If the pump does not prime after 30

seconds of cycling, try tapping the inlet valve with a

small wrench to jar the balls loose.

tap here

9564A

NOTE: Excessive shock

will fracture or cause other

damage to the pump.

If the sprayer continues to cycle (motor and pump run)

after you release the gun trigger, the pump valves may

be obstructed or worn. If they are worn, the XR Valve

Kits (shown Kits Diagram) are available.

HINT: To be certain about whether the inlet valve ball is

sticking, you can unscrew the inlet valve from the pump

and check it. MAGNUM XR7 and XR9 sprayers allow for

inlet valve removal without removing the suction tube.

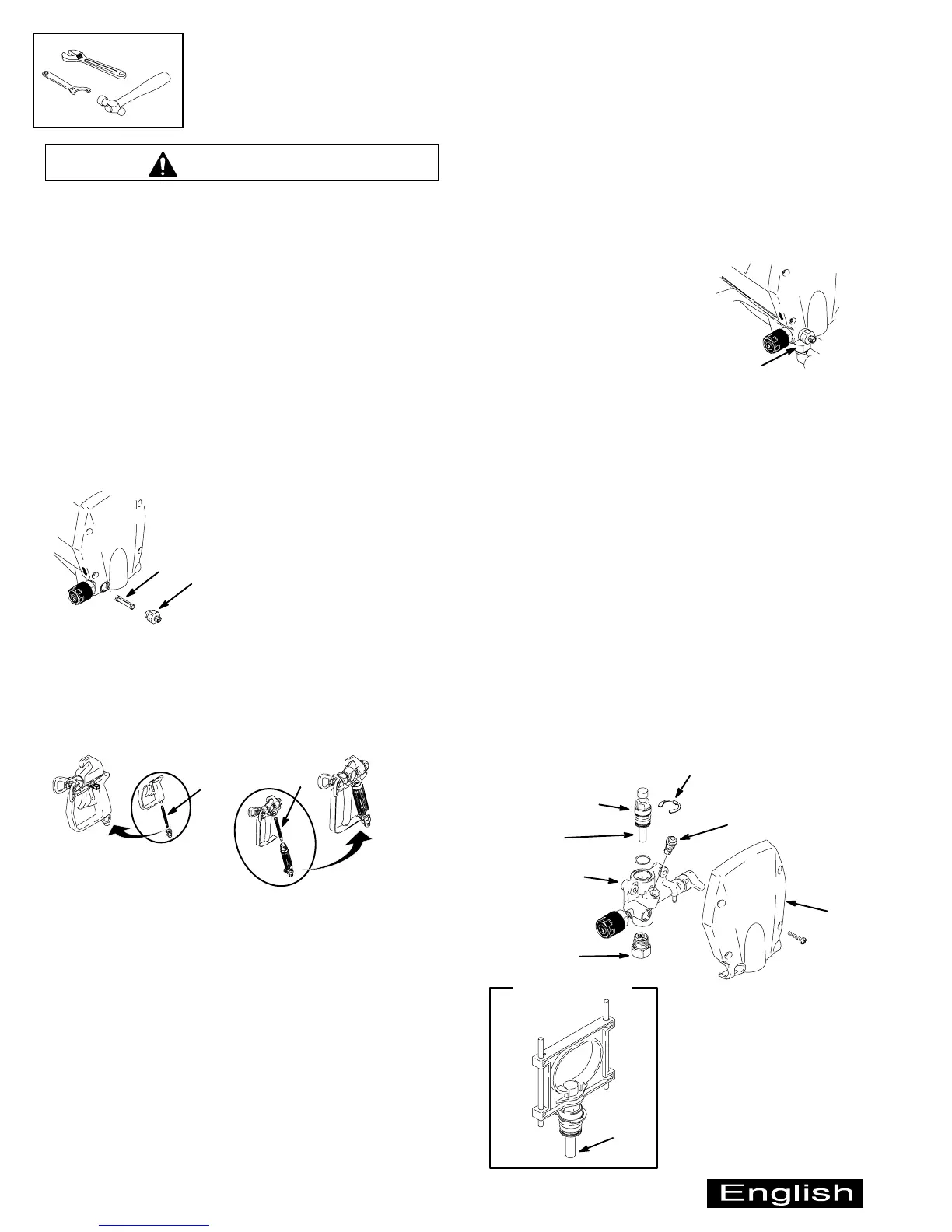

Pump Packings

When the pump packings wear, paint will begin to leak

down the outside of the pump. Replace the pump

packings at the first sign of leaking, or additional damage

could occur. Obtain an XR Pump Repair Kit (shown in

Kits Diagram), and install according to the instructions

on the kit packaging.

XR Pump Repair

Kit 243090

front

cove

pump

XR Outlet Valve

Kit 243094

XR Inlet Valve

Kit 243093

Kits Diagram

HINT: If leaking occurs in the middle of a paint job,

remove this clip, and tighten the existing packing module

all the way down. This will allow you to spray a few more

gallons before you have to install the XR Pump Repair Kit.

9569A

For best cover alignment,

tighten lower two cover

screws first, then top two.

Torque screws to 70 to

80 in-lb (8 to 9 NSm).

Rod/Yoke Detail

rod

rod

Loading...

Loading...