Location

8

Components A and B

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that in this manual:

Component A refers to resin or major volume.

Component B refers to the hardener or minor volume.

NOTE:

This equipment doses the B component into the A com-

ponent flow. An integration hose must always be used

after the mix manifold and before the static mixer.

NOTE:

Please follow these recommendations for setup:

• use at least a 3/8 in. (10 mm) x 25 ft. (7 m) hose as

the integration hose.

• install a 24-element static mix tube after the integra-

tion hose.

Keep Components A and B Separate

Changing Materials

• When changing materials, flush the equipment mul-

tiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers and outlet filter

after flushing, Flush Mixed Material, page 16.

• Check with your material manufacturer for chemical

compatibility.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the A (resin)

side.

NOTE:

If the amine will switch between the two sides, see

Flush Mixed Material, page 16.

Location

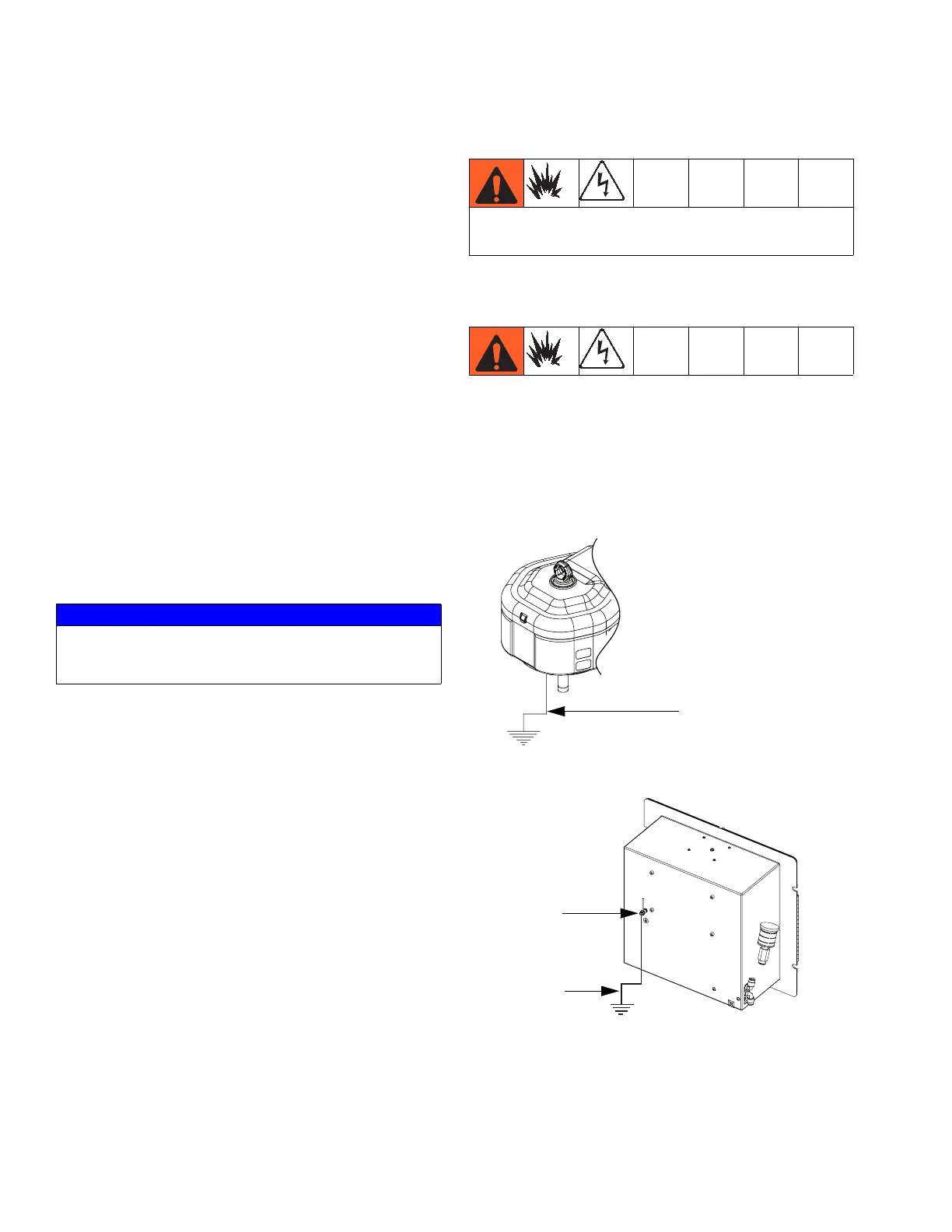

Grounding

Ground control box (ground wire attached) and both air

motors to a true earth ground.

NOTE:

If wall power is used, ground electrical connection prop-

erly according to local codes.

NOTICE

To prevent cross-contamination of the equipment’s wet-

ted parts, never interchange component A (resin) and

component B (hardener) parts.

XM OEM sprayers are not approved for use in hazard-

ous locations.

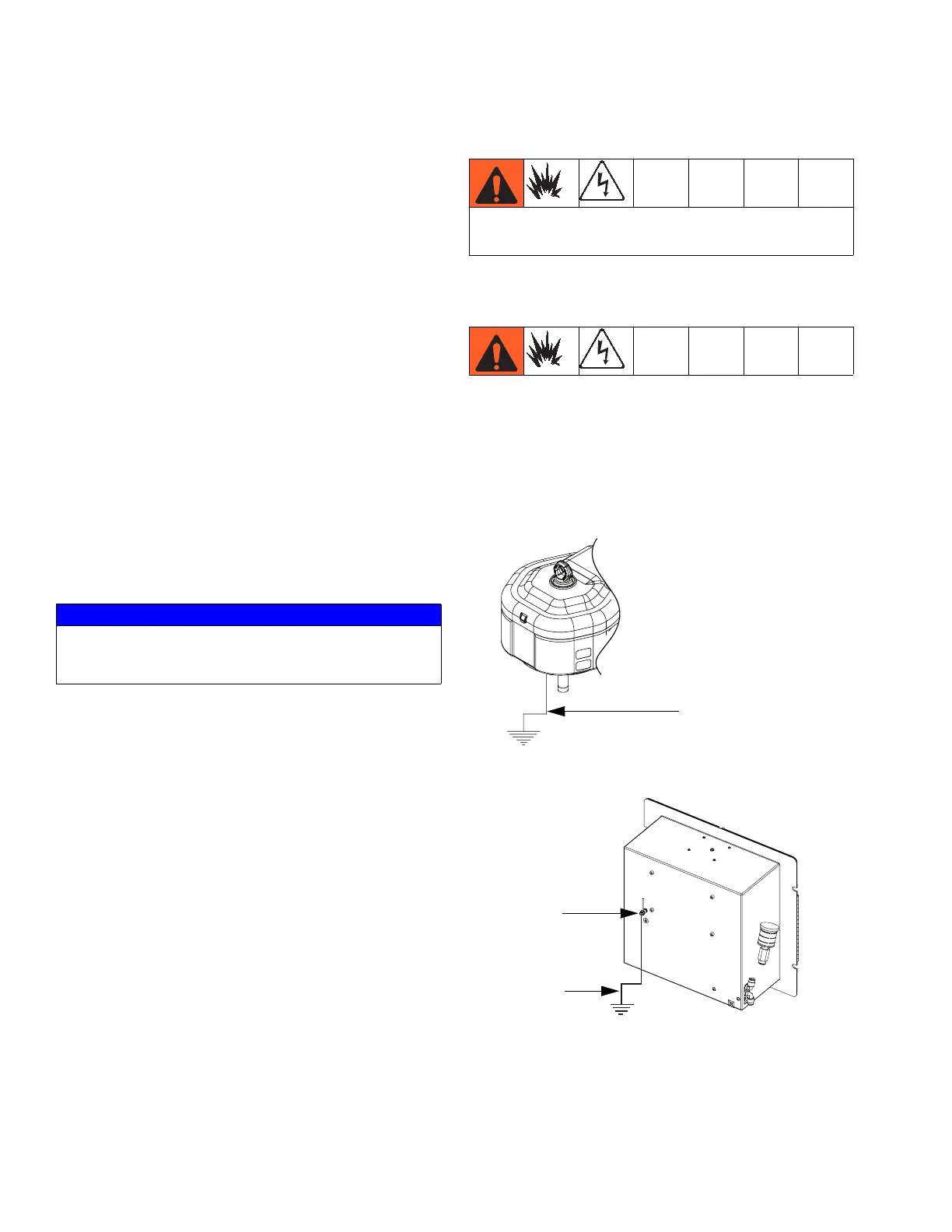

Air Motor

Ground Wire

Control Box

Ground Nut

Control Box

Ground Wire

Loading...

Loading...