Unstirred water bath SAP, JBA, JBN Service Manual (Version 1.0) September 2013

31667 Page 17 of 23

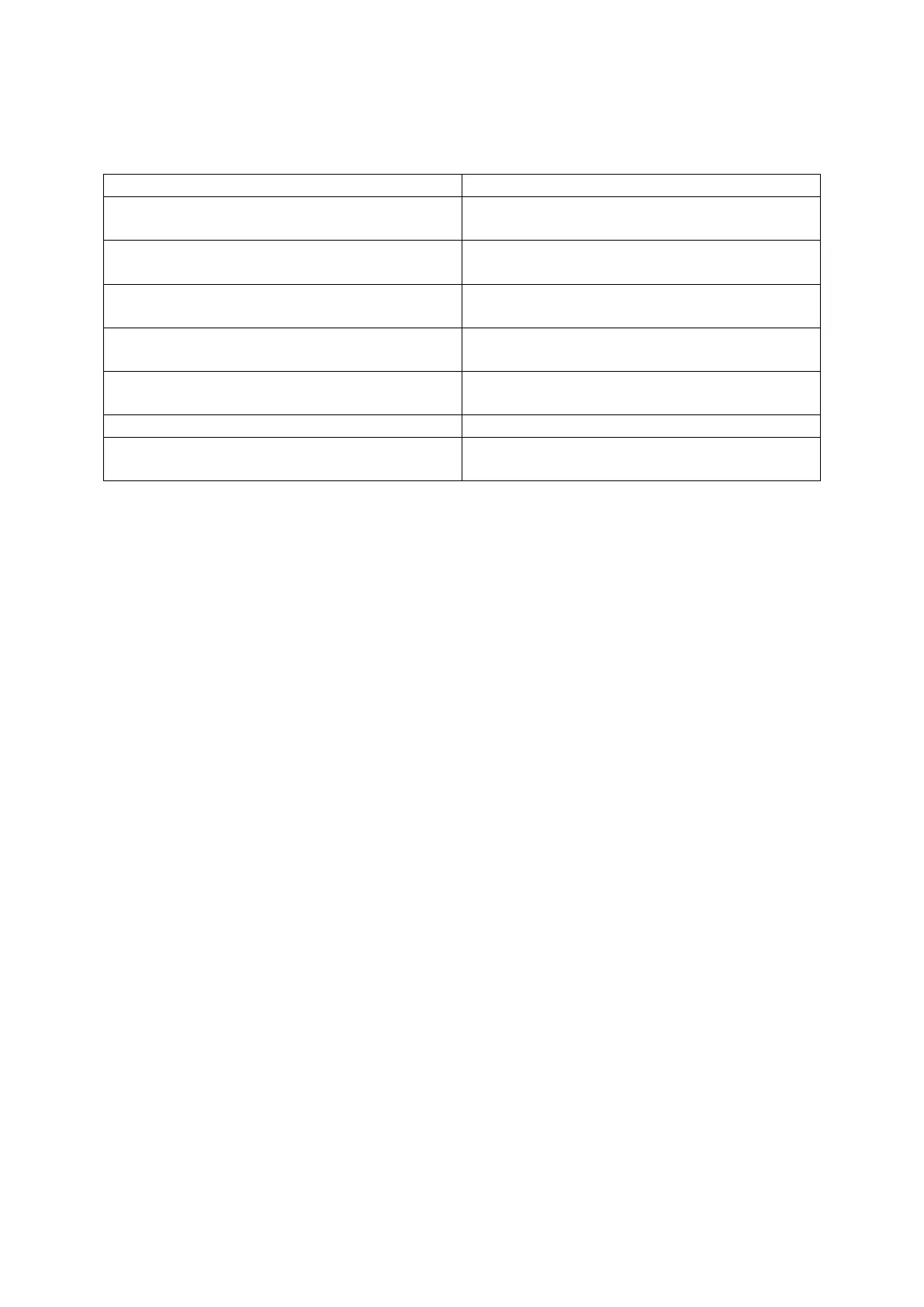

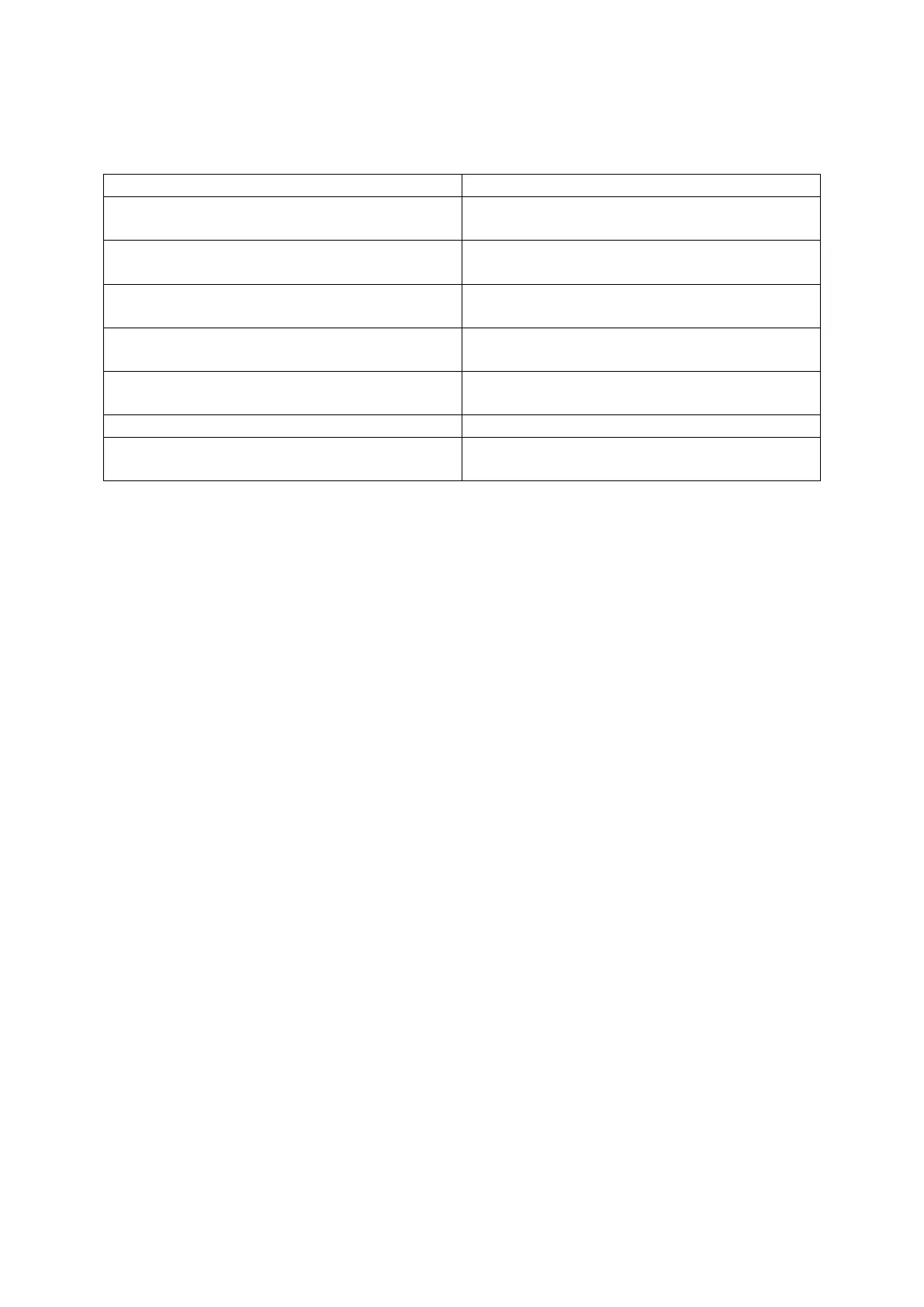

4.2.2 Useful values for fault finding

68-80Ω (120V)

252-294Ω (230V)

Heater 2 litre shallow & 5 litre models

39-45Ω (120V)

144-168Ω (230V)

17-20Ω (120V)

63-74Ω (230V)

Heater 18 litre & 26 litre models

13-15Ω (120V)

36-42Ω (230V)

10.5-12.5Ω (120V)

28-32Ω (230V)

See 5 litre and 12 litre values above

approx 1070 to 1120Ω at room temperature

(18-31°C)

4.3 Final Tests – Electrical Safety

After any repair, the unit should be electrically tested to ensure that it is safe.

WARNING: The following process should always be carried out after any repair to ensure

safety. If the bath fails either test below then it must be repaired and successfully retested

before being put back into operation.

4.3.1 Check Earth Connection

Using an Ohm meter or, preferably, a specialised earth bond checker (max 25A test current),

verify that the resistance between the earth pin of the equipment inlet and the exposed

metalwork is less than 0.1Ohm. In the case of the painted panels it is acceptable to make the

contact with the screw heads.

4.3.2 Check Insulation

Use a high voltage tester set to 2000VDC. Connect the live and neutral terminals of the bath

together and apply the test voltage between them and the earth contact of the bath. The test

voltage should be raised to its full value in less than 2 seconds, held for 2 seconds and then

reduced back to zero.

No breakdown or repeated flashover shall occur. Corona effects and similar phenomena are

disregarded

4.3.3 Routine testing

If routine tests are to be made, we recommend a test of the integrity of the protective

earth conductor and an insulation test at 500V DC. Routine flash tests are not

recommended for any electrical equipment, because repeated high voltage tests degrade

insulation materials.

Loading...

Loading...