THROTTLE

Run the engine at full

throttle

when operating

under load, especially

with

power driven equipment.

• Do not idle the engine

for

prolonged periods

of

time,

• overheating may result causing engine damage. Over

all, the engine works best at full throttle. (3600 RPM)

HEAD LIGHTS

The Ignition Switch must

be

in the "RUN" position

before lights will work on all models. The engine on

the 816S also must be running.

GROUND SPEED

Experiment

by

varying

ground

speed to find the

optimum

speed that the equipment will satisfactorily

do

the job. The ground speeds suggested below are

dependent upon conditions.

1.

Ground

Engaging Attachments: SLOW ground

speed

2.

Mowing: MEDIUM ground speed

3.

Transporting: HIGH ground speed

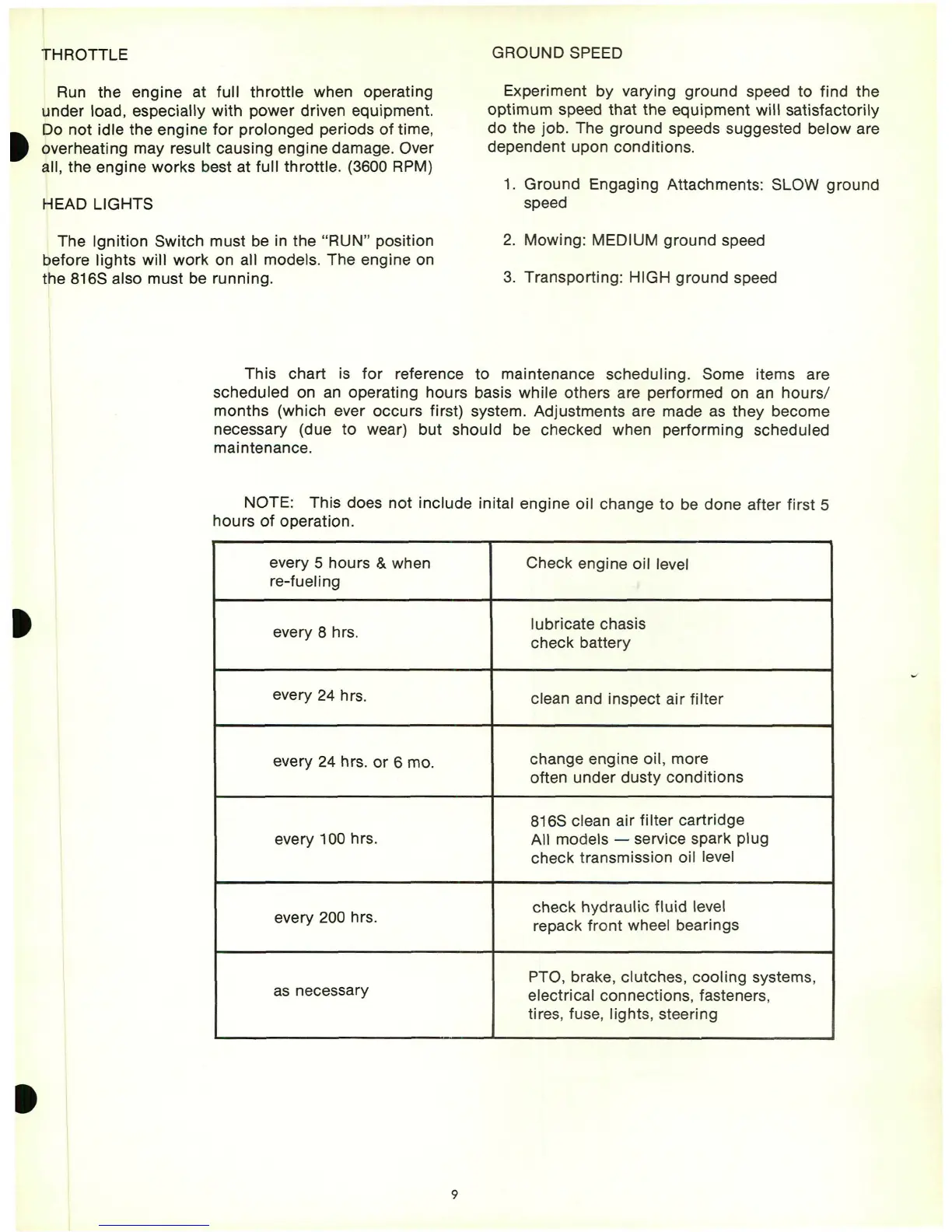

This chart is

for

reference to maintenance scheduling. Some items are

scheduled on

an

operating hours basis while others are performed on an

hours/

months (which ever occurs first) system. Adjustments are made

as

they become

necessary (due

to

wear) but should be checked when performing scheduled

maintenance.

NOTE: This does

not

include inital engine oil change

to

be done after first 5

hours

of

operation.

every 5 hours

& when

Check engine oil level

re-fueling

every 8 hrs.

lubricate chasis

check battery

every 24 hrs.

clean and inspect

air

filter

every 24 hrs.

or

6 mo.

change engine oil, more

often under dusty

conditions

816S clean air filter cartridge

every 100 hrs. All models - service spark plug

check transmission oil level

every 200 hrs.

check hydraulic fluid level

repack front wheel bearings

PTO, brake, clutches, cooling systems,

as

necessary

electrical connections, fasteners,

tires, fuse, lights, steering

I

9

Loading...

Loading...