GMV5 DC INVERTER VRF UNITS SERVICE MANUAL

21

Chapter 2 Installation

Part 1 Engineering Installation

Preparation

I. Installation Safety

Personnel and property safety are highly concerned during the entire installation process.

Installation implementation must abide by relevant national safety regulations to ensure personnel and

property safety.

All personnel involved in the installation must attend safety education courses and pass

corresponding safety examinations before installation. Only qualified personnel can attend the

installation. Relevant personnel must be held responsible for any violation of the regulation.

II. Importance of Installation Engineering

VRF air conditioning systems use refrigerant, instead of other agent, to directly evaporate to carry

out the system heat. High level of pipe cleanness and dryness is required in the system. Since various

pipes need to be prepared and laid out onsite, carelessness or maloperation during installation may

leave impurities, water, or dust inside refrigerant pipes. If the design fails to meet the requirement,

various problems may occur in the system or even lead to system breakdown.

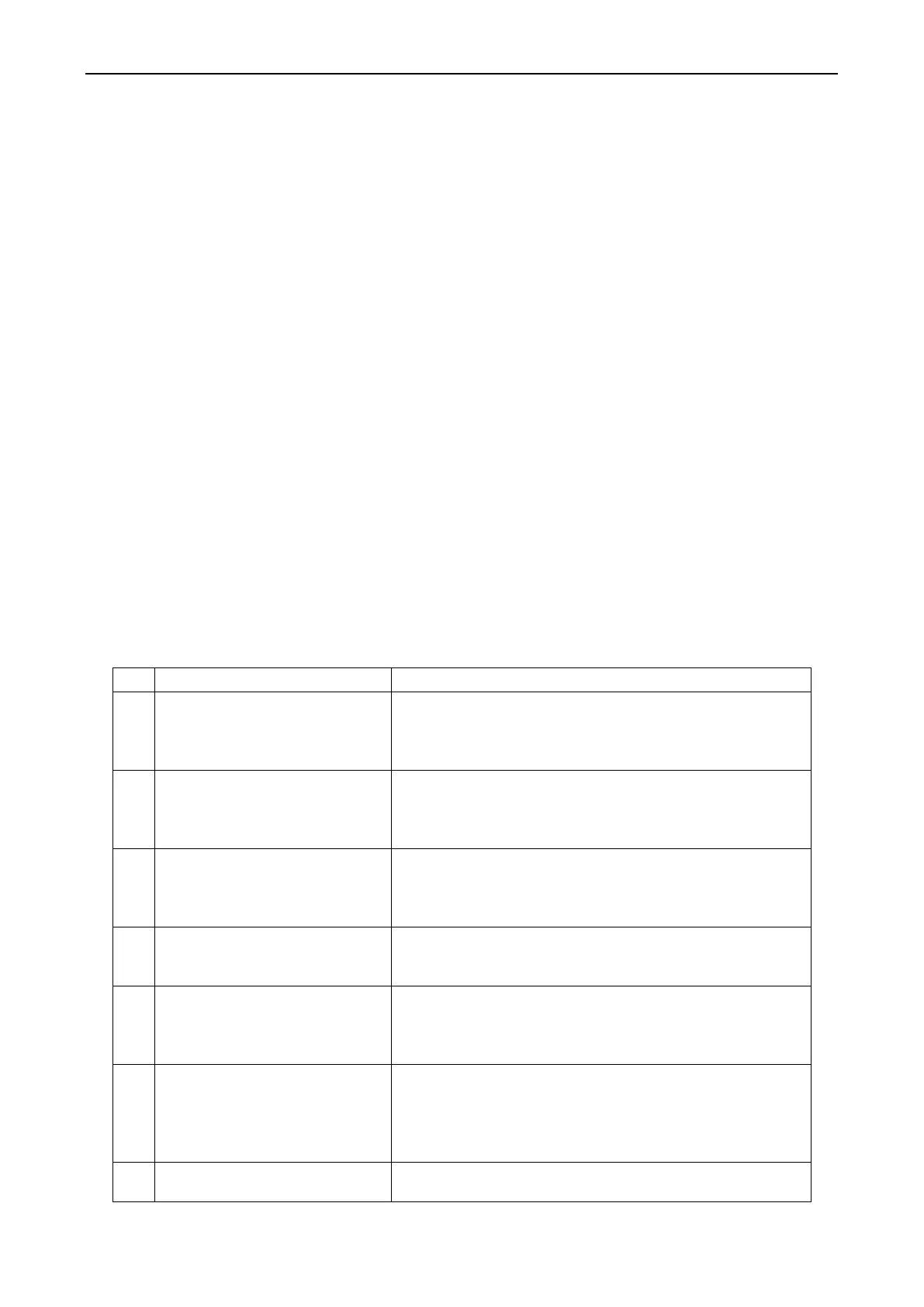

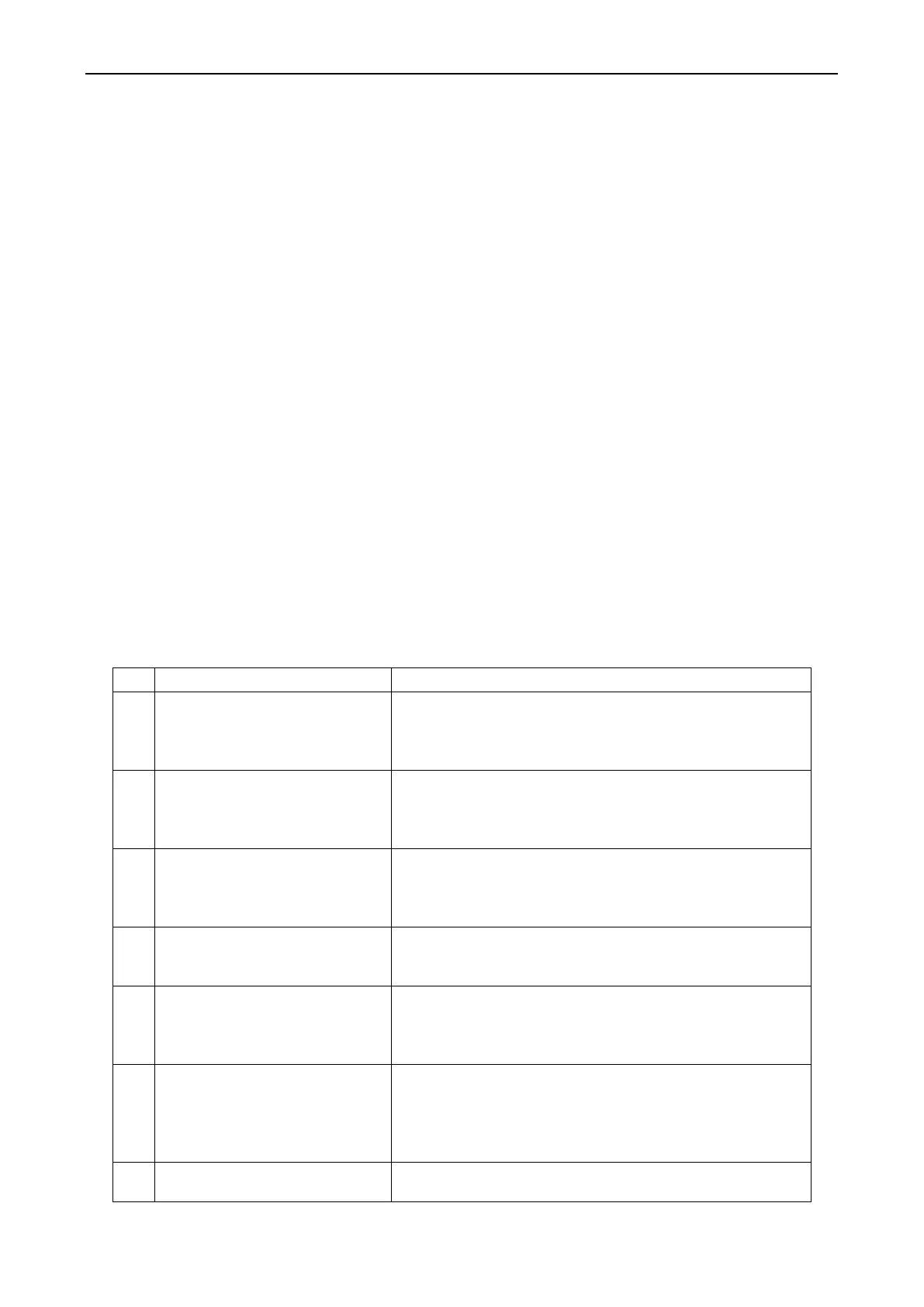

Problems that usually occur during installation are as follows:

Dust or impurities enter into the

refrigeration system.

Pipes are more likely to be blocked; air conditioning performance is

reduced; compressor wear is increased

or even hinder the normal operation of the system and burn the

compressor.

Nitrogen is not filled into the

refrigerant pipe or insufficient

Nitrogen is filled before welding.

Pipes are more likely to be blocked; air conditioning performance is

reduced; compressor wear is increased

or even hinder the normal operation of the system and burn the

compressor.

The vacuum degree in the refrigerant

pipe is insufficient.

The refrigeration performance is reduced. The system fails to keep

normal operation due to frequent protection measures. When the

problem getting serious, compressor and other major components

can be damaged.

Water enters into the refrigeration

system.

Copper plating may appear on the compressor and reduce the

compressor efficiency with abnormal noise generated; failures may

occur in the system due to ice plug.

The refrigerant pipe specifications do

not meet the configuration

requirements.

Smaller configuration specifications can increase the system pipe

resistance and affect the cooling performance; larger configuration

specifications are waste of materials and can also reduce the cooling

performance.

Refrigerant pipe is blocked.

The cooling performance is reduced; in certain cases,

it may cause long-term compressor operating under overheat

conditions; the lubricating effect can be affected and the

compressor may be burnt if impurities were mixed with the

lubricating oil.

Refrigerant pipe exceeds the limit.

The loss in pipe is considerable and the unit energy efficiency

decreases, which are harmful for long-term running of the system.

Loading...

Loading...