3

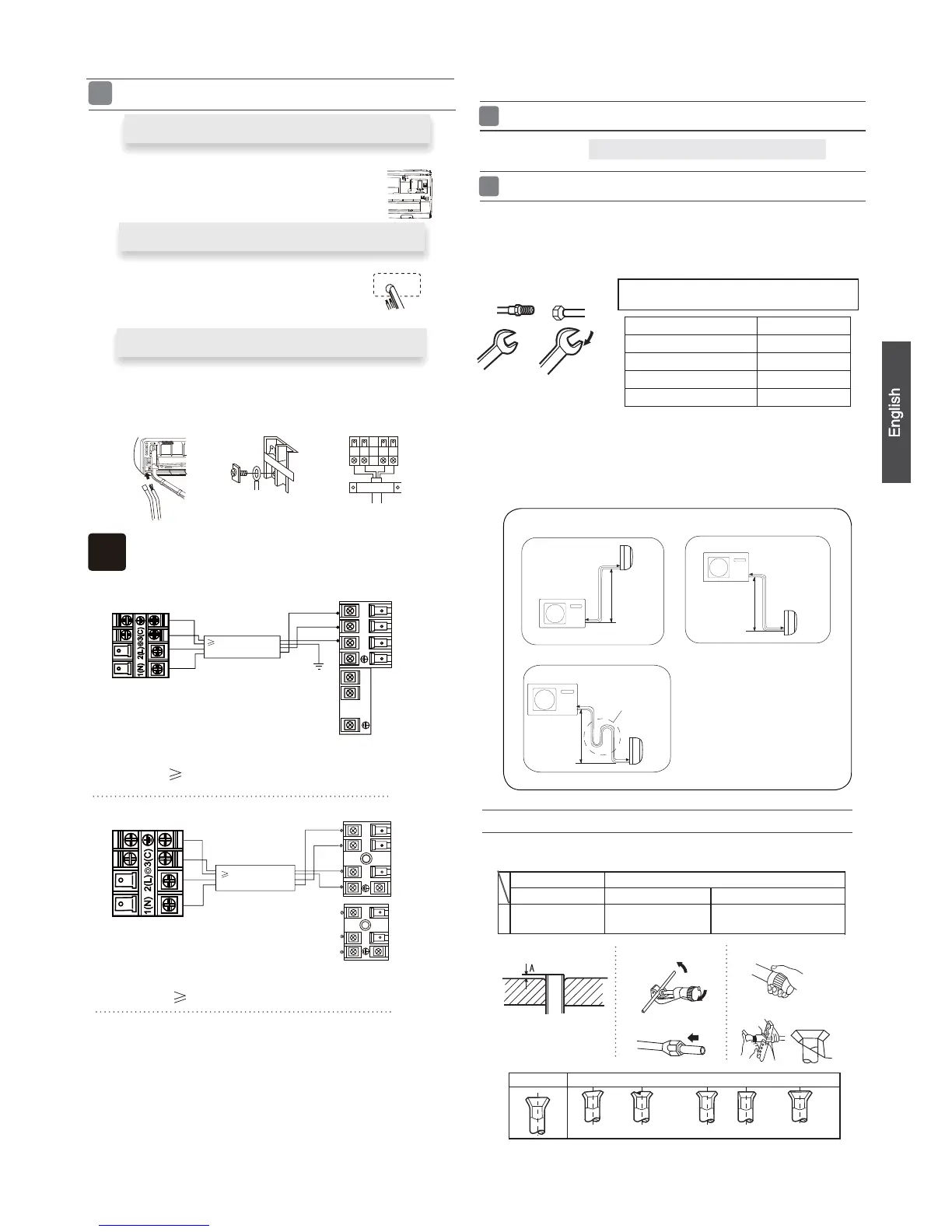

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

B

Outdoor unit

Indoor unit

Oil trap

Outdoor unit

Install according to the instructions on the 1st page of this manual

When bending the interconnect tubing, ensure the radius is at least 1 1/4" to 1 3/4",

30mm to 40mm to ensure against crushing the tubing.

ƽ

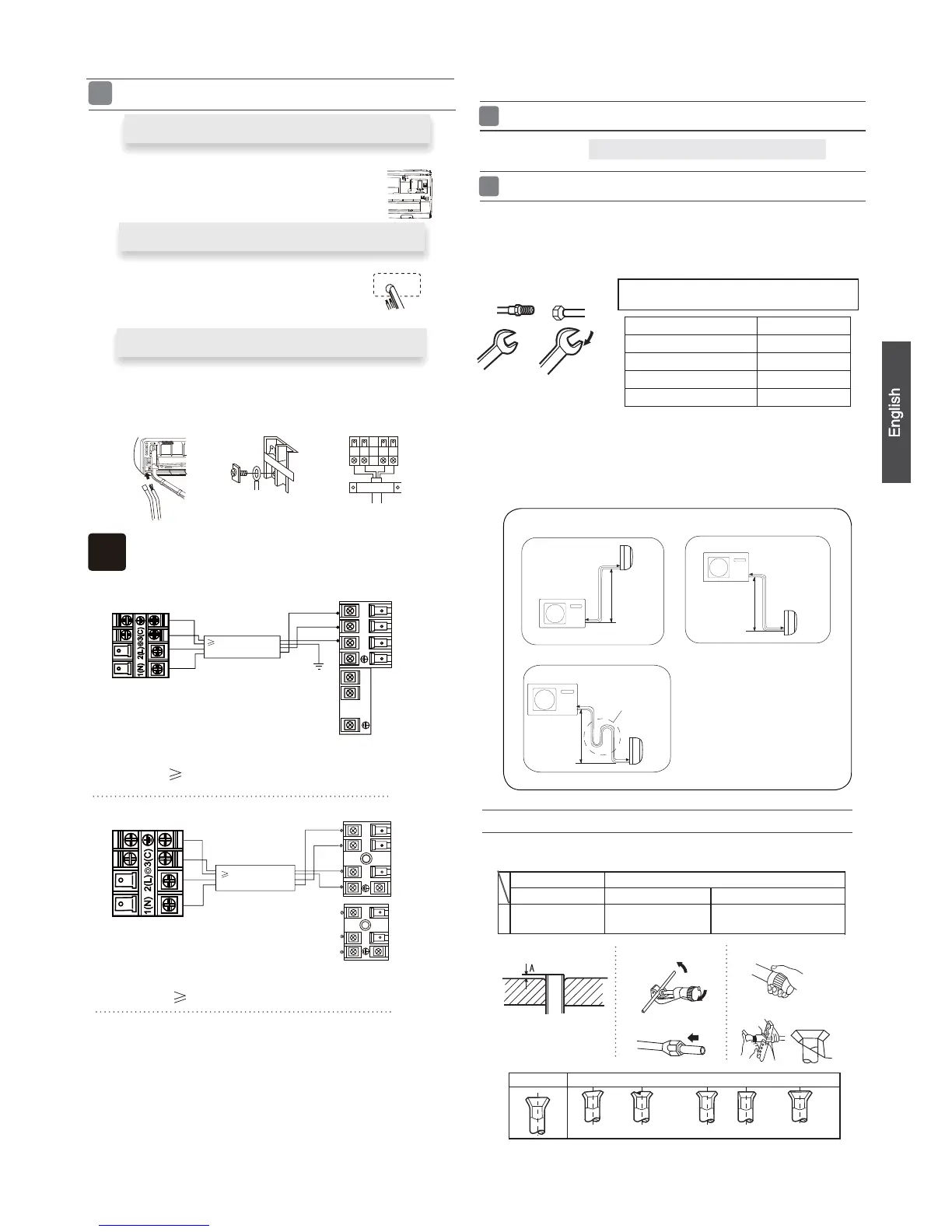

Connecting the pipe of gas side first makes working easier.

ƽ

Ensure the interconnecting tubing is approved for R410A.ƽ

Installation of Outdoor Unit

Half union

Flare nut

Torque wrench

CAUTION

Spanner

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Connection of pipes

1.Ifthesupplycordisdamaged,itmustbereplacedbythemanufacturerorits

service agent or a similar qualified person. The type of connecting wire is

H05RN-F

or H07RN-F.

2.IfthefuseonPCboardisbrokenpleasechangeitwiththe

type of

3.Thewiringmethodshouldbeinlinewiththelocalwiringstandard.

4. Use an HVACR circuit breaker or time delay fuse.

T.3.15A/250VAC (Indoor), T.25A/250VAC (Outdoor).

Connecting the indoor/outdoor Electric Cable

Removing the wiring cover

Remove terminal cover at right bottom corner of indoor unit, then take offƽ

wiringcoverbyremovingitsscrews.

1. Insert the cable from the outside into the unit through the same

hole that has the interconnecting tubing.

2.Pulloutthecableonthefrontside,andconnectthecable

making a loop.

Note

When connecting the cable, confirm the terminal number of indoor and

outdoor units carefully. If wiring is not correct, the unit will not operate

When connecting the cable after installing the indoor unit

When connecting the cable before installing the indoor unit

Indoor unit

)C

(3

)

N

(1

)L(

2

)

C

(3

)

N

(

1)L(2

^

Outdoor unit

{

Indoor unit

Outdoor unit

1

2

N

2

)

(

3

(C)

L

1

)

(

•

Max.Elevation: Amax

= 32ft / 10m (09k / 12k)

= 50ft / 15m (18k / 24k)

•

In case the elevation A is more

than 15ft / 5m, oil trap shoud be

installed every 5~7m

•

Max. Length: Bmax

= 50ft / 15m (09k / 12k)

= 80ft / 25m (18k / 24k)

HSU09VHG(DB)-W

HSU12VHG(DB)-W

HSU18VHG(DB)-W

HSU24VHG(DB)-W

ƽ

ƽ

ƽ

Insert the cord from the back side of the unit, then pull it out on the front side.

Fasten the unit wire harness to the conduit holder using the lock nut.

Position the conduit holder to its original state using screw.

Power

Wiring

4wire 18AWG

Control Wiring

Power cable:

2wire with ground 16AWG

Power cable:

2wire with ground 12AWG (4G0.75 mm )

Power

Wiring

4wire 18AWG

Control Wiring

Pipe Diameter(ǿ) Fastening torque

Liquid side6.35mm(1/4") 18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2") 55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8") 60 N.m/44.3Ft.lbs

properly and could cause a defect.

(4G0.75mm )

2

(4G0.75 mm )

2

(4G0.75mm )

2

2

Ensure that no dirt or debris enters the tubing. The standard tubing length is 15 ft., 5M.

If a different length is required, adjust the refrigerant amount by 1/4 oz/ft, 20 g/M for the

9k, 12k and 18k models. For the 24k model, adjust by 1/2 oz/ft, 40 g/M.Before opening

the service valves, evacuate the interconnecting tubing and indoor unit. Follow the

instruction in section 5 on page 4.

Pipe cutting is carried out with a pipe cutter and burs must

ƽ

be removed.

After inserting the flare nut, flaring work is carried out.

ƽ

CuttingandFlaringWorkofPiping

FlaretoolforR410A Conventionalflaretool

Clutch-type clutch-type(Rigid-type) Wing-nut type (Imperial-type)

A

0~0.5mm

1.0~1.5mm

1.5~2.0mm

0~1/51 inch

3/76 ~1/17 inch

1/17 ~1/8 inch

Flare tooling die

1.Cut pipe

2.Remove burs

3.Inserttheflarenut

4.Flare pipe

Lean

Damage of flare Partial Too outside

Correct Incorrect

Crack

Loading...

Loading...