11

Adjust the HARDI-MATIC valve 6 so that the pressure gauge indicates

the recommended pressure.

ADJUST THE PRESSURE EQUALIZATION SECTIONS AS FOL-

LOWS:

7. Note the pressure and place the first lever 3 on the distribution valve

in position B (off position).

8. Turn the corresponding adjust screw 5 until the pressure gauge

again shows the same pressure (turn the screw clockwise for higher

pressure, anti-clockwise for lower pressure).

9. Adjust the other sections of the distribution valve in the same way.

NB: HEREAFTER ADJUSTMENT OF PRESSURE EQUALIZATION

WILL ONLY BE NEEDED IF YOU CHANGE TO NOZZLES WITH

OTHER CAPACITIES.

10. Operating the control unit while driving:

To close the entire boom, turn the handle 2 to position B. This takes

the pressure off the pump. The liquid will then return to the tank via the

return system. The diaphragm anti-drip valves ensure instantaneous

closing of all nozzles. In order to close part of the boom, move lever 3

of the distribution valve to position B (off position) for the section or

sections to be closed. The pressure equalization device ensures that

the pressure does not rise in the sections which are to remain open.

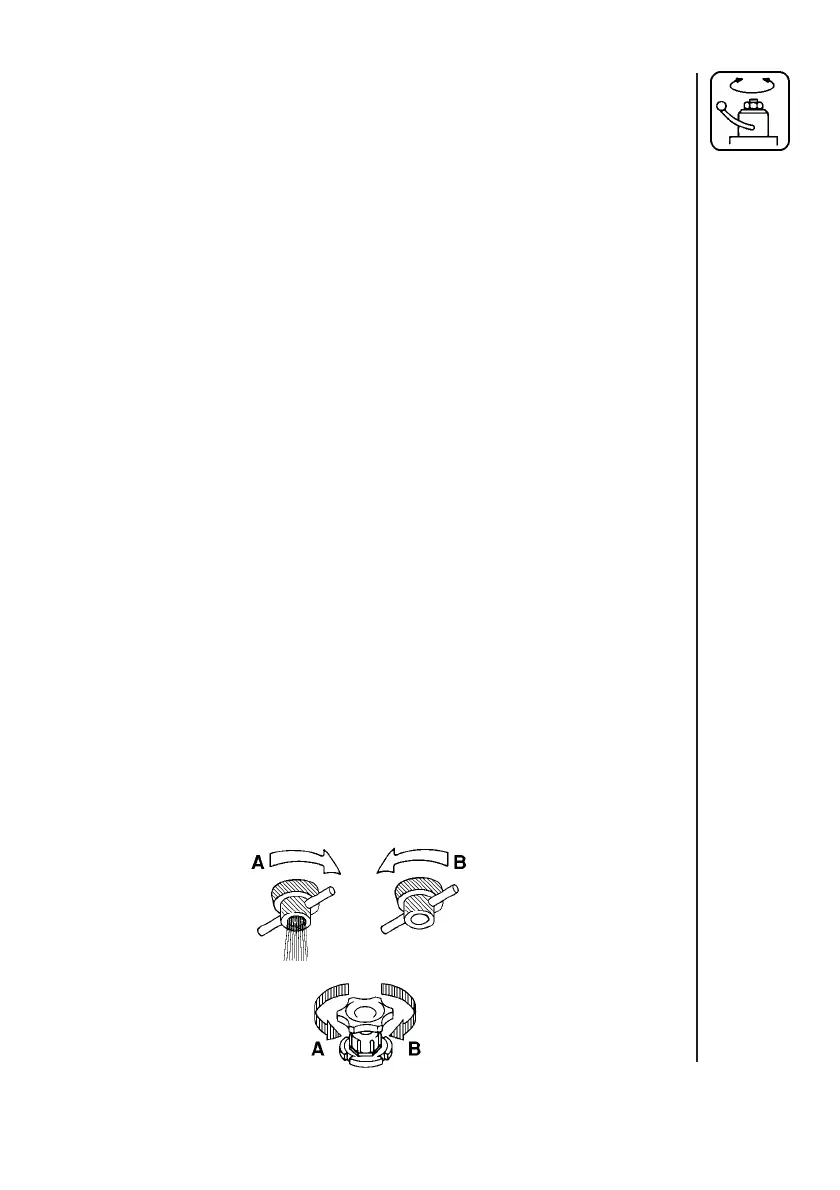

Drain valve operation

Pressure filter

The operating unit has an in-built pressure filter. It is not necessary to

dismantle the filter to clean it. When cleaning the sprayer (clean water

circulating in the tank), open the drain valve to flush the filter;

To open : A

To close : B

Tank drain

To open : A

To close : B