~

-

~

~

~

I

Always~eargloveswhen

OPERATION

operating the stove.

The Combustion Process

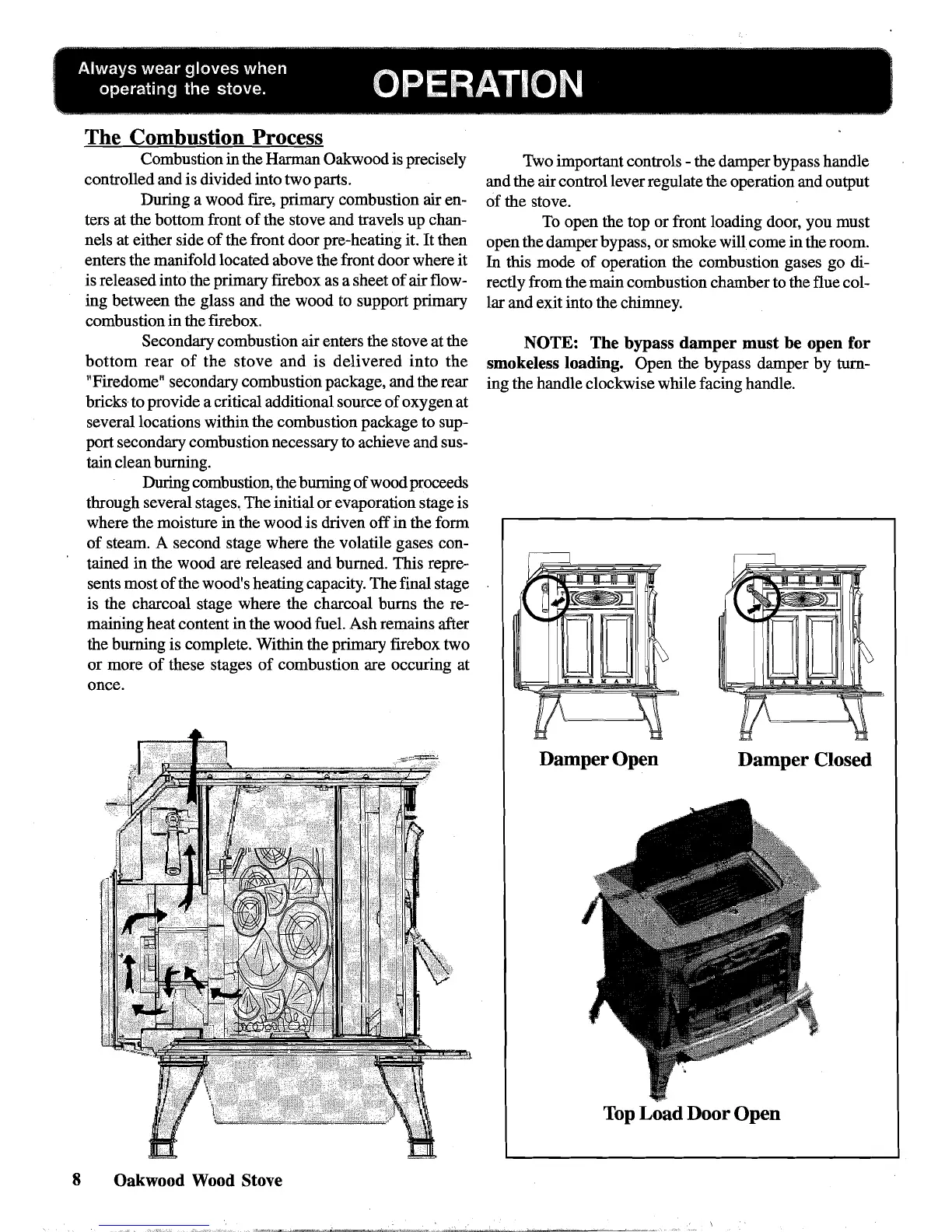

Combustion in the Harman Oakwood is precisely

controlled and is divided into two parts.

During a wood fire, primary combustion air en-

ters at the bottom front

of

the stove and travels up chan-

nels at either side

of

the front door pre-heating it.

It

then

enters the manifold located above the front door where

it

is released into the primary firebox as a sheet

of

air flow-

ing between the glass and the wood to support primary

combustion

in

the firebox.

Secondary combustion air enters the stove at the

bottom

rear

of

the

stove

and

is

delivered

into

the

"Firedome" secondary combustion package, and the rear

bricks to provide a critical additional source

of

oxygen at

several locations within the combustion package to sup-

port secondary combustion necessary to achieve and sus-

tain clean burning.

During combustion, the burning

of

wood proceeds

through several stages. The initial

or

evaporation stage is

where the moisture

in

the wood

is

driven

off

in

the form

of

steam. A second stage where the volatile gases con-

tained in the wood are released and burned. This repre-

sents most

of

the wood's heating capacity. The final stage

is the charcoal stage where the charcoal

bums

the re-

maining heat content in the wood fuel. Ash remains after

the burning is complete. Within the primary firebox two

or

more

of

these stages

of

combustion are occuring at

once.

8 Oakwood

Wood

Stove

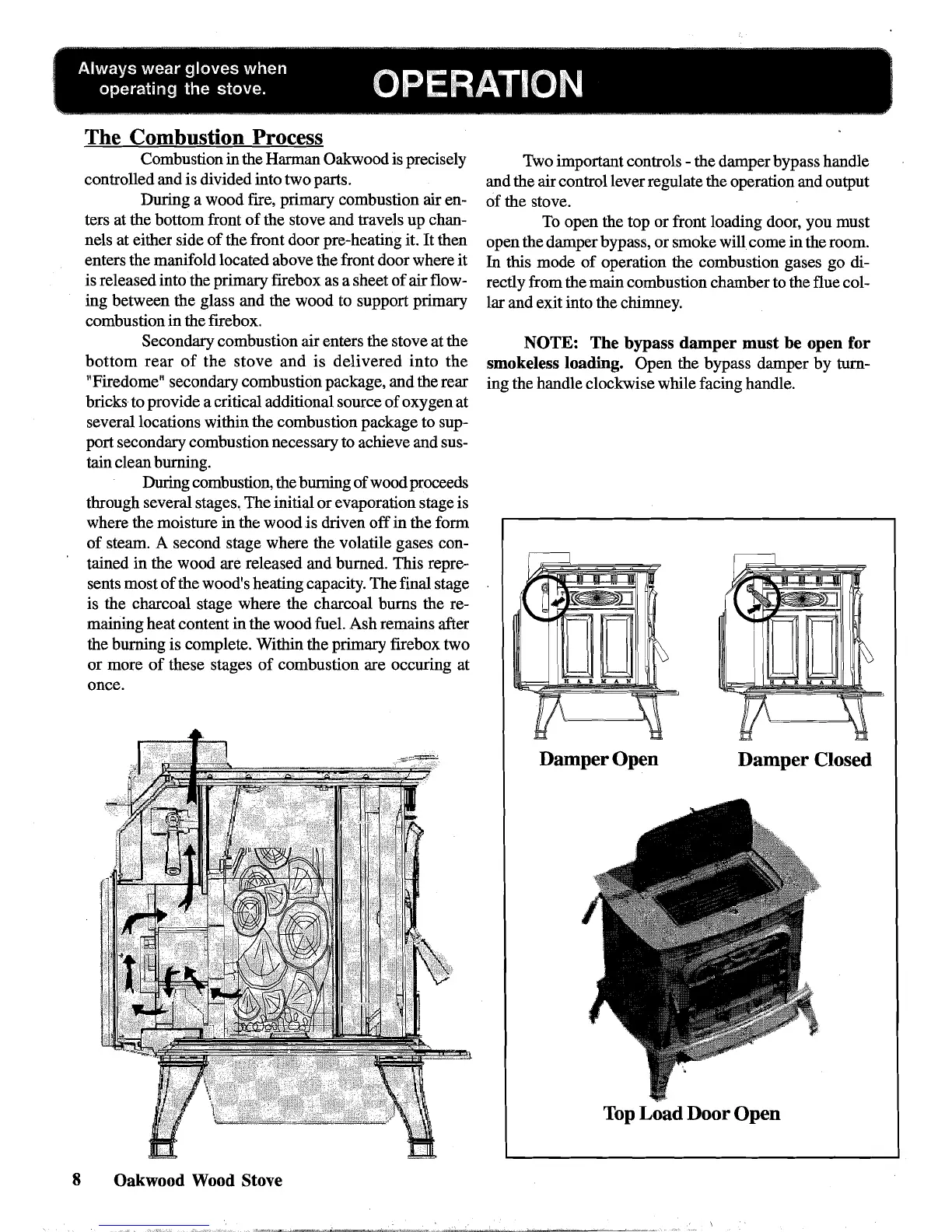

Two important controls - the damper bypass handle

and the air control lever regulate the operation and output

of

the stove.

To

open the top or front loading door, you must

open the damper bypass,

or

smoke will come

in

the room.

In

this mode

of

operation the combustion gases go di-

rectly from the main combustion chamber to the flue col-

lar and exit into the chimney.

NOTE: The bypass damper must be open for

smokeless loading.

Open the bypass damper

by

turn-

ing the handle clockwise while facing handle.

Damper Open

Damper

Closed

Top Load Door

Open

Loading...

Loading...