9

3-90-08101R23_06/13

Venting

Design

Therstthingneededisdecidingwhereandhowthefurnace

willbeinstalled.

ThingsthatneedtobetakenintoconsiderationareVenting,

Supply and Return Ducting, Electrical, and Condensation

Drainage (ifA/C is installed). Don’t forget access to the

furnaceforservice.

Whenthereturnairinletpositionisknown,thelterboxand

distributionblowercanbeinstalled.Afterthefurnaceisset

intoplace,theventingcanbecompleted.

Venting

Use 4” pellet vent pipe only.

A combustion blower is used to extract the combustion

gasesfromtherebox.Thiscreatesanegativepressurein

thereboxandapositivepressureintheventingsystemas

showning.2.Thelongertheventpipeandmoreelbows

usedinthesystem,thegreatertheowresistance.Because

of these facts, we recommend using as few elbows as

possible and 30 feet or less of vent pipe. The maximum

horizontalrun should not exceed 18 feet. Remember, the

horizontal pipe sections will accumulate with y-ash rst.

Keepthisareaclean.

Be sure to use wall and ceiling pass through ttings

which are approved for pellet vent pipe when going

through combustible materials. Besuretouseastarting

collar to attach the venting system to the furnace. The

starting collar must be sealed to the furnace ue collar

with high temp silicone caulking or aluminum tape, and

screwed into the ue collar at least three (3) places.

Vent Pipe

4”pelletventpipe(knownasPLvent)isconstructedoftwo

layerswithairspacebetweenthelayers.Thisairspaceacts

asaninsulatorandreducestheoutsidesurfacetemperature

toallowaclearancetocombustiblesaslowas2inches.This

clearanceistestedandlistedbythepipemanufacturers.

Thesectionsofpipelocktogethertoformanairtightseal

in most cases; however, in some cases a perfect seal is

notachieved.Forthisreasonandthefactthatthefurnace

operateswithapositiveventpressure,we specify that all

joints within the structure should also be sealed with

high-temp silicone.

Fig. 1

NOTE: Read and follow all of the vent pipe

manufacturers’ instructions on the proper installation

and support of the vent pipe. Adhere to all clearances.

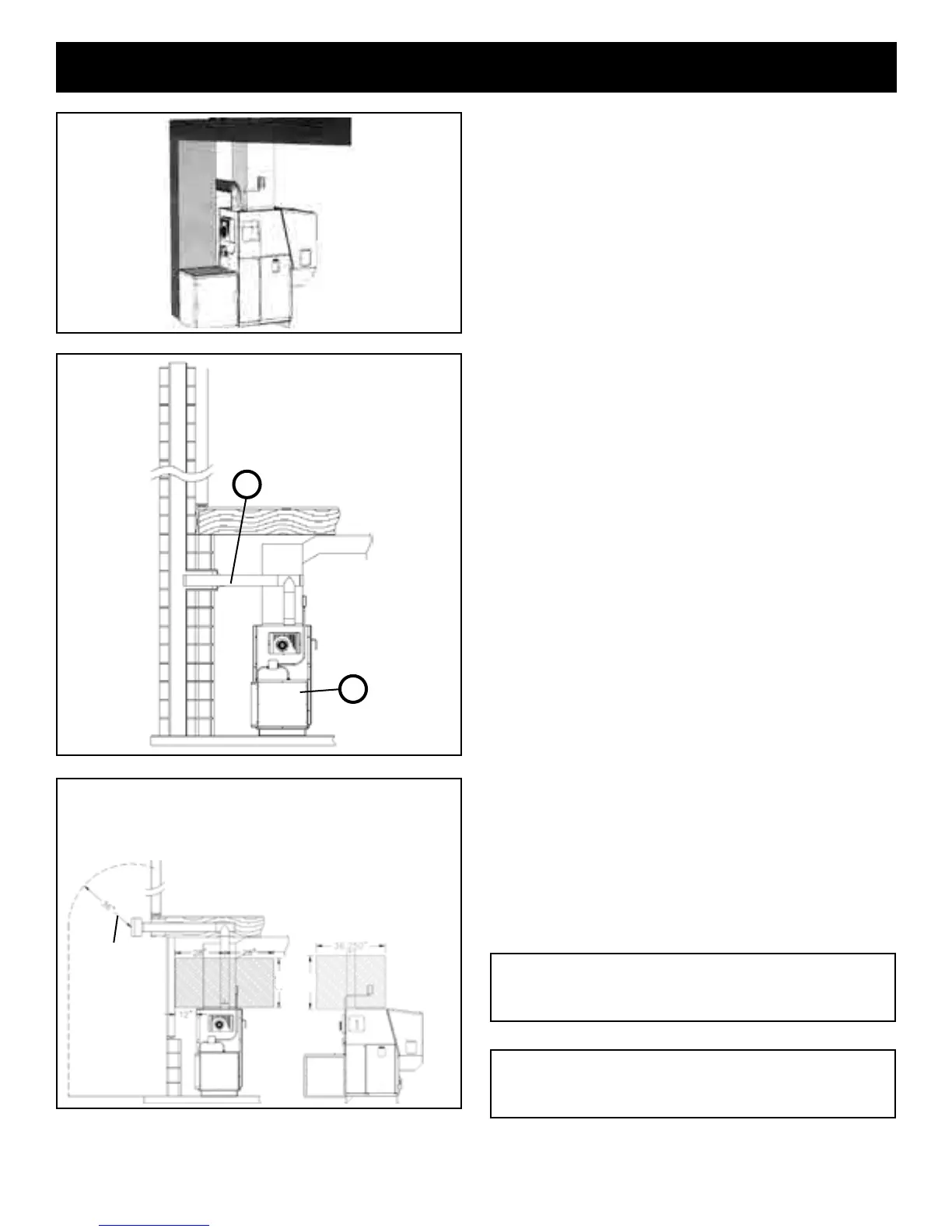

Clearances and Venting

Theshadedareasarewheretheclearances

forthePLventpipemustbemaintained

at3”.Aftertheventingleavestheshaded

area it may be installed as per the vent

manuafacturerinstructions.(Onlylistedwall

pass-throughsandrestopsmaybeused.)

See NOTES:

on page 12

16”

16”

NOTE: Use only 4” diameter “PL” venting system.

Be sure to inspect and clean exhaust venting system

frequently.

Fig. 2

+

-

Loading...

Loading...