5

English

HOW TO USE

CAUTIONS

䡬 Do not remove the insulation cover. It is necessary

to support the body of the tool.

䡬 During operation, the base of the tool should be

pressed against the material, as shown in Fig. 6,

herein. If the tool is not properly pressed against

the maerial, the blade may be damaged by vibration.

1. Cutting metallic materials

Ensure the material is firmly held in position during

operation. Always use an appropriate cutting agent

(spindle oil, soapy water, etc.). When a liquid cutting

agent is not available, apply grease to the material

to be cut.

2. Cutting lumber

When cutting lumber, ensure that the wooden

material is firmly fixed in position.

3. Sawing curved lines

Use a No. 6 or No. 7 blade (optional accessories)

as described below.

䡬 For metal-working - No. 6

䡬 For wood-working - No. 7

When sawing a small circular arc, reduce the feeding

speed of the machine.

4. Cut off guide for cutting pipe (optional accessory)

NOTE

Please refer to the cut off guide user’s manual for

details on how to use ti correctly.

SELECTION OF BLADES

To ensure maximum operating efficiency and results, it

is very important to select the appropriate blade best

suited to the type and thickness of the material to be cut.

Three types of blades are provided as standard

accessories.

The blade number is engraved in the vicinity of the

mounting position of each blade. Select appropriate

blades by refering to Tables 1 and 2 below.

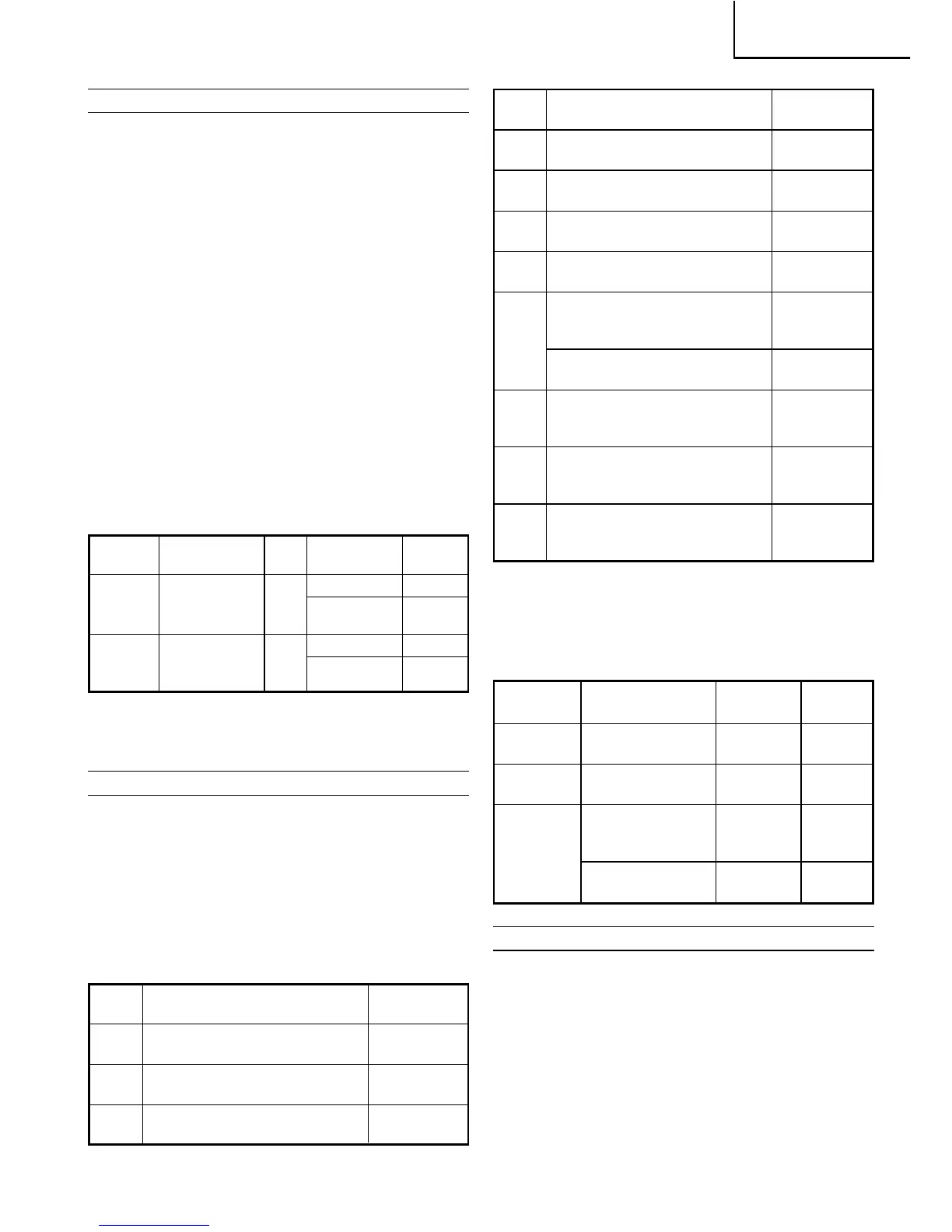

Table 1

Product

Cutting Blade Applicable

Code No.

application

used products

Cut-off Outer diameter

Model CR10V 984449

guide (L)

75mm – 175mm

No. 9

Model CR12,

CR12V

996420

Cut-off Outer diameter

Model CR10V 984448

guide (S) 10mm – 55mm

No. 1

Model CR12,

996429

CR12V

NOTE

No. 2, No. 4, No. 6, No. 7, No. 8, No. 9, No. 95,

and No. 96 blades are sold separately.

For other materials.

Table 2

MAINTENANCE AND INSPECTION

1. Inspecting the blade

Continued use of a dull or damaged blade will

result in reduced cutting efficiency and may cause

overloading of the motor. Replace the blade with

a new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

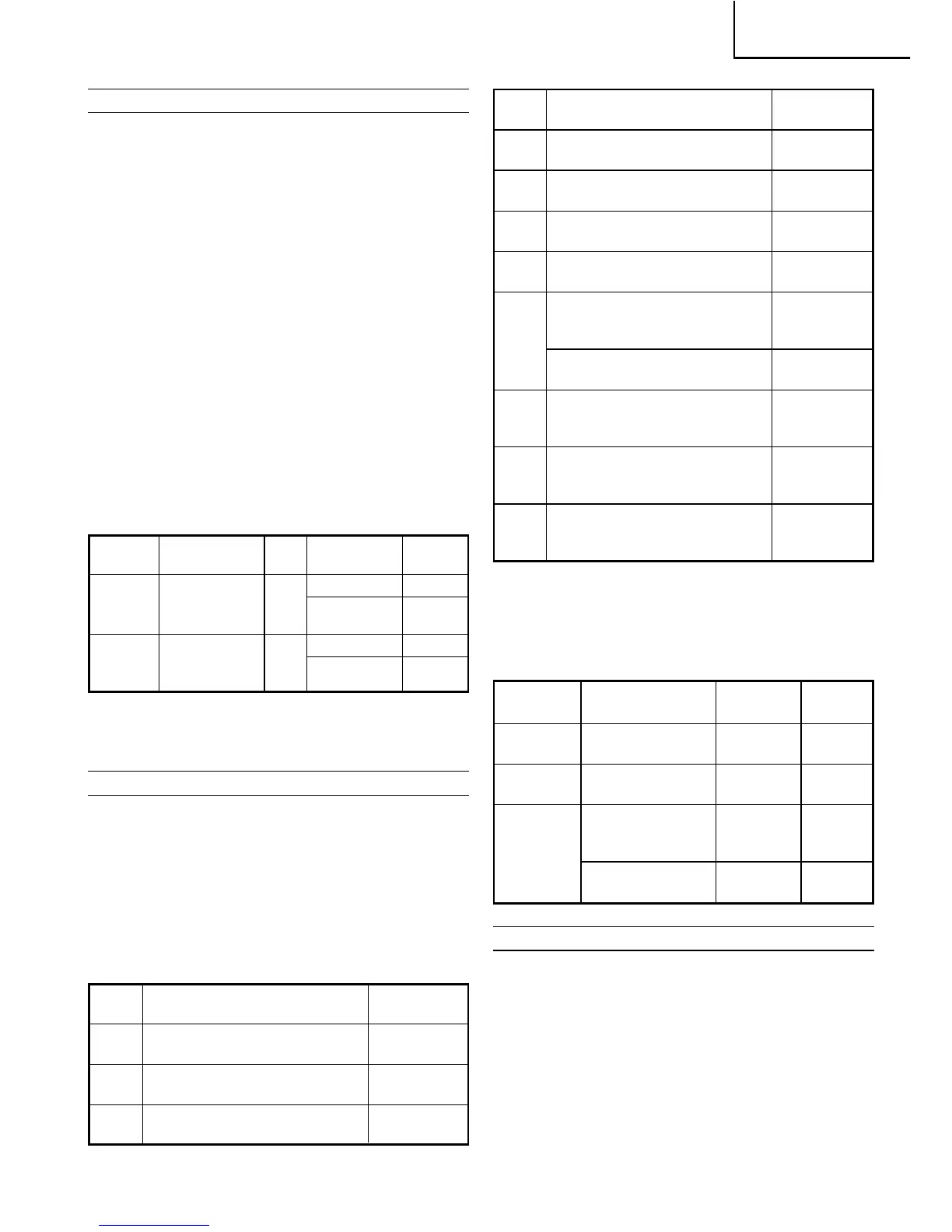

Blade

Uses

Thickness

No. (mm)

No.1

For cutting steel pipe less

than 115mm in diameter

2.5 – 6

No.2

For cutting steel pipe less

than 40mm in diameter

2.5 – 6

No.3

For cutting steel pipe less

than 40mm in diameter

Below 3.5

Blade

Uses

Thickness

No. (mm)

No.4

For cutting and roughing

lumber

50 – 100

No.5

For cutting and roughing

lumber

Below 50

No.6

For sawing curved lines

iron plate

Below 3.5

No.7

For sawing curved lines

lumber

Below 30

No.8

For cutting vinyl chloride

pipe less than 115mm in

diameter

2.5 – 15

For cutting and roughing

lumber

Below 50

No.9

For cutting mild steel pipe

less than 175mm in diameter

when used with cut off guide

2.5 – 6

No.95

For cutting stainless steel

pipe less than 115mm in

diameter

Below 2.5

No.96

For cutting stainless steel

pipe less than 40mm in

diameter

Below 2.5

Material

Material quality

Thickness Blade

to be cut (mm) No.

Iron plate Mild steel plate

Below 3.5 No.3,6

2.5 – 12 No.1,2

Nonferrous Aluminium, Below 5 No.3,6

metal Copper, Brass 5 – 20 No.1,2

Synthetic

Phenol resin,

restin

Melamine

5 – 30 No.3,5,8

resin, etc.

10 – 50 No.1,2,4,

Vinyl chloride 5 – 30 No.3,5,8

Acrylic resin, etc. 10 – 60 No.1,2,4

Loading...

Loading...