- 28 -

7. Oil

WARNING

• Please use only pure gear oils for lubrication as the movements of the mechanical brake

and slip clutch may be affected resulting in performance degradation if lubricant oils other

than pure gear oils are used. Please replace old gear oil early as continued use of old gear

oil may hasten gear wear and result in noise.

• When replacing the gaskets with new ones, the gear oils may spread initially but this will not

progress further as the gaskets are swelling-type gaskets.

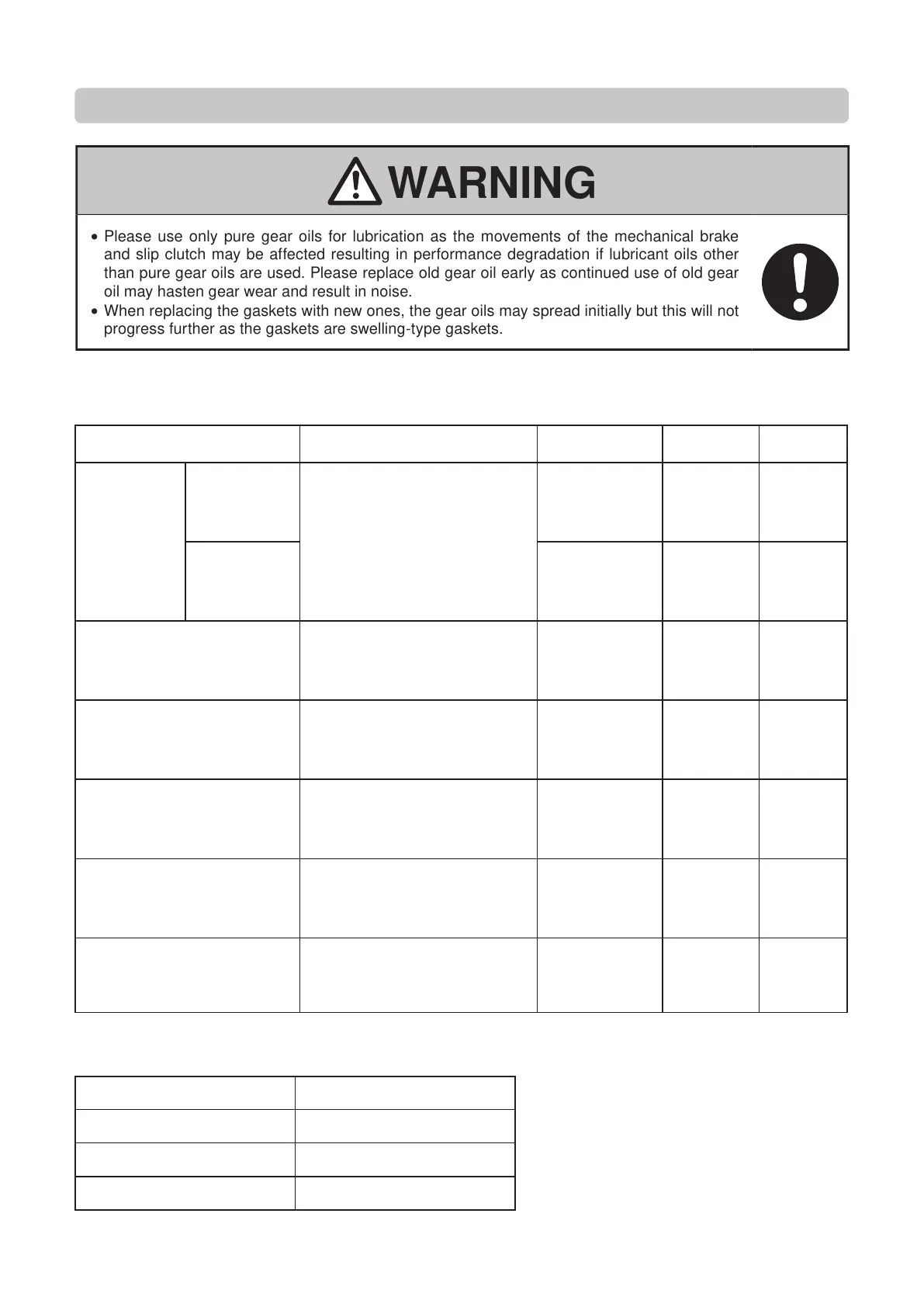

The oiling criteria are shown in the table below. As these are applicable for standard use only, a suitable oiling

method needs to be established after checking the actual usage condition.

* When filling or changing oil, wipe old grease and iron dust before putting in new grease.

* Wipe as needed when oil separated from grease accumulates on the cover or other parts.

Oiling Location Type of Oil

Application

Amount

Volume

Oiling

Criteria

Upper / Lower

hook assembly

Hook thrust

bearing

EPINOC grease No.1

(JXTG Nippon Oil & Energy corp.)

or NIPPECO SEP No.1

(NIPPECO LTD.)

About 3g Twice a year

Suspention pin

Enough to cover

the surface

Once a year

Coupling

Moly PS grease No.2

(Sumico Lubricant co LTD.)

or CALFOREX EP No.2

(NIPPECO LTD.)

About 10g Once a year

Reduction gear

Moly PS grease No.2

or NIPPECO SEP No.1

(NIPPECO LTD.)

About 80g Twice a year

Apply to

teeth

Limit lever (ball / pin surface) Moly PS grease No.2

Enough to cover

the surface

Once a year

Chain

Tonna Oil S3 M 220

(Parts code: 836492)

About 30g Once a week

Apply to

meashing

part

Rolor Moly PS grease No.2 About 1g Once a year

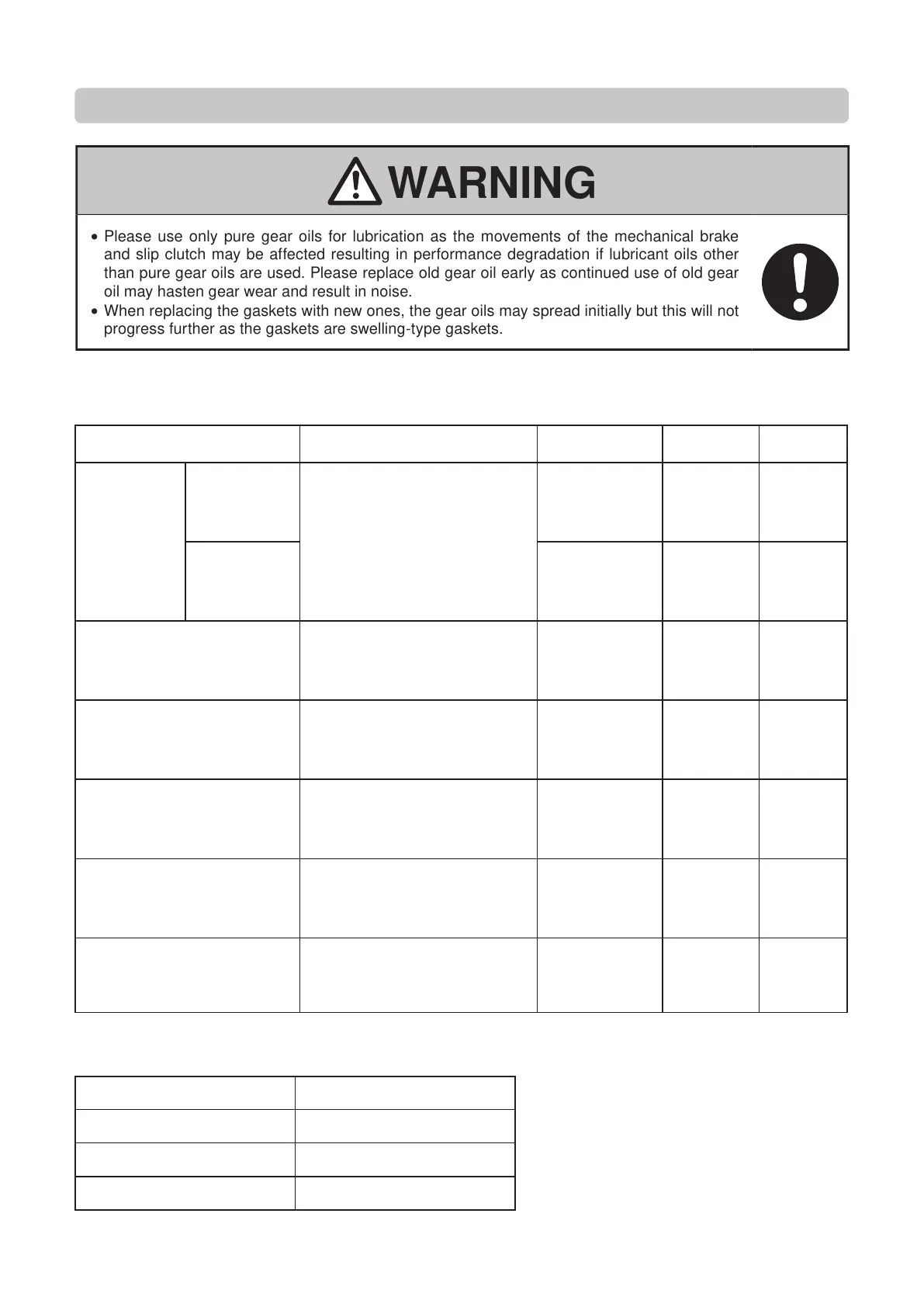

Type of Oil PART No.

NIPPECO SEP No.1 813872

Moly PS grease No.2 850089

Tonna Oil S3 M220 836492

Loading...

Loading...