? NOTE

• The indoor unit is equipped with an automatic air purger (factory

supplied) at the highest location of the indoor unit. Anyway, if there

are higher points in the water installation, air might be trapped inside

water pipes, which could cause system malfunction. In that case,

additional air purgers (eld supplied) should be installed to ensure

no air enters into the water circuit. The air vents should be located at

points which are easily accessible for servicing.

• The water pressure indicated on the indoor unit manometer may vary

depending on the water temperature (the higher temperature, the

higher pressure). Nevertheless, it must remain above 1 bar in order

to prevent air from entering the circuit.

• Fill in the circuit with tap water. The water in the heating installation

must comply with EN directive 98/83 EC. Non-sanitary controlled

water is not recommended (for example, water from wells, rivers,

lakes, etc.)

• The maximum water pressure is 3 bar (nominal opening pressure of

the safety valve). Provide adequate reduction pressure device in the

water circuit to ensure that the maximum pressure is NOT exceeded.

• For heating oor system, air should be purged by means of an external

pump and an open circuit to prevent the formation of air pockets.

• Check carefully for leaks in the water circuit, connections and circuit

elements.

5 ELECTRICAL AND CONTROL

SETTINGS

5.1 GENERAL CHECK

• Make sure that the following conditions related to power

supply installation are satised:

- The power capacity of the electrical installation is large

enough to support the power demand of the YUTAKI

system (outdoor unit + indoor unit + DHW tank (if apply)).

- The power supply voltage is within ±10% of the rated

voltage.

- The impedance of the power supply line is low enough

to avoid any voltage drop of more than 15% of the rated

voltage.

• Following the Council Directive 2014/30/EU, relating to

electromagnetic compatibility, the table below indicates the

Maximum permitted system impedance Z

max

at the interface

point of the user’s supply, in accordance with EN61000-3-11.

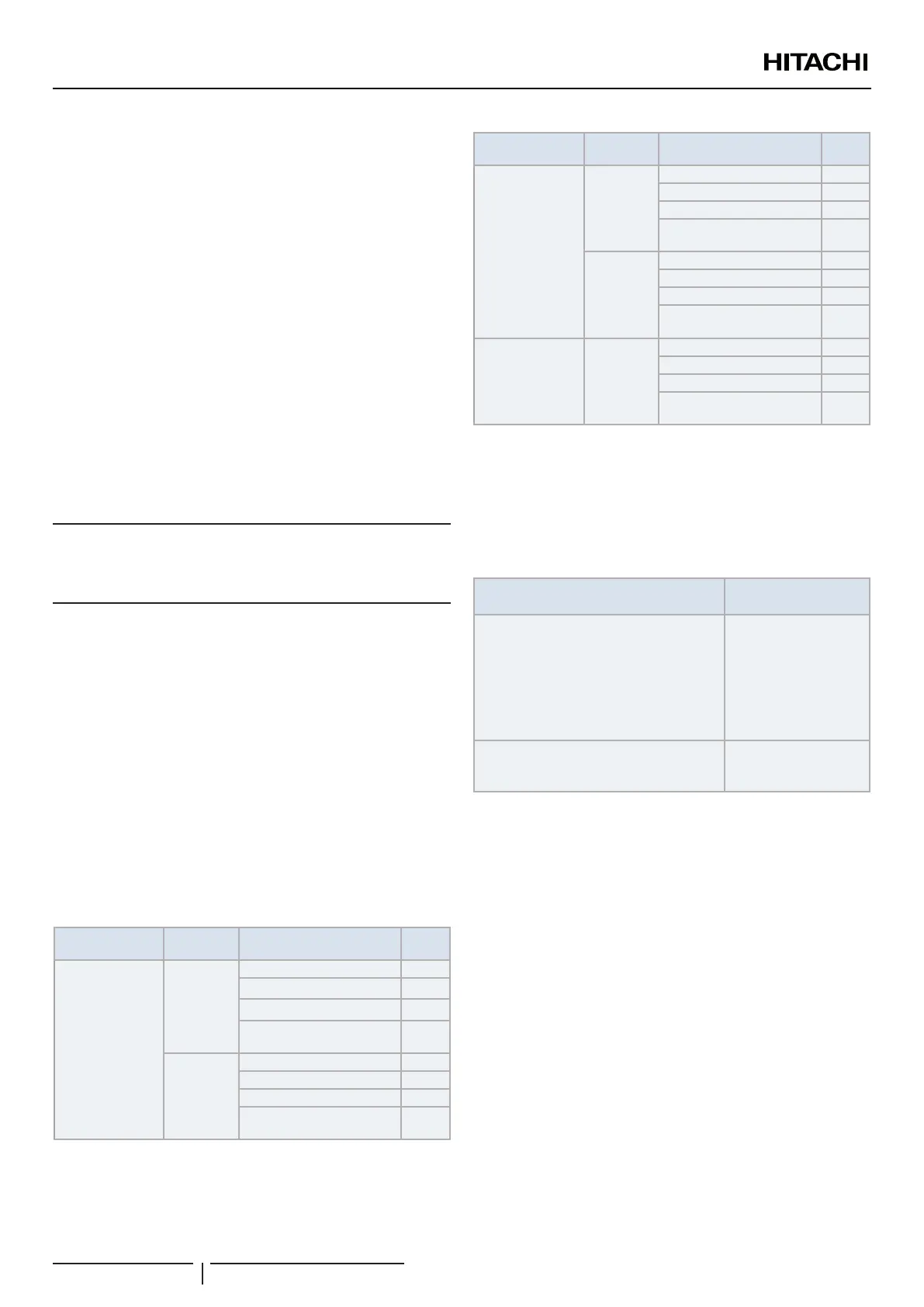

Model

Power

supply

Operation mode

Z

max

(Ω) (*)

RWM-(2.0-3.0)R1E

1~ 230V

50Hz

Without electric heaters -

With electric heater -

With DHW tank heater -

With electric and DHW tank

heaters

0.28

3N~ 400V

50Hz

Without electric heaters -

With electric heater -

With DHW tank heater -

With electric and DHW tank

heaters

-

Model

Power

supply

Operation mode

Z

max

(Ω) (*)

RWM-(4.0-6.0)N1E

1~ 230V

50Hz

Without electric heaters -

With electric heater 0.28

With DHW tank heater -

With electric and DHW tank

heaters

0.19

3N~ 400V

50Hz

Without electric heaters -

With electric heater -

With DHW tank heater -

With electric and DHW tank

heaters

-

RWM-(8.0/10.0)N1E

3N~ 400V

50Hz

Without electric heaters -

With electric heater -

With DHW tank heater -

With electric and DHW tank

heaters

-

? NOTE

The data corresponding to DHW tank heater is calculated in combination

with the domestic hot water tank accessory “DHWT-(200/300)S-3.0H2E”.

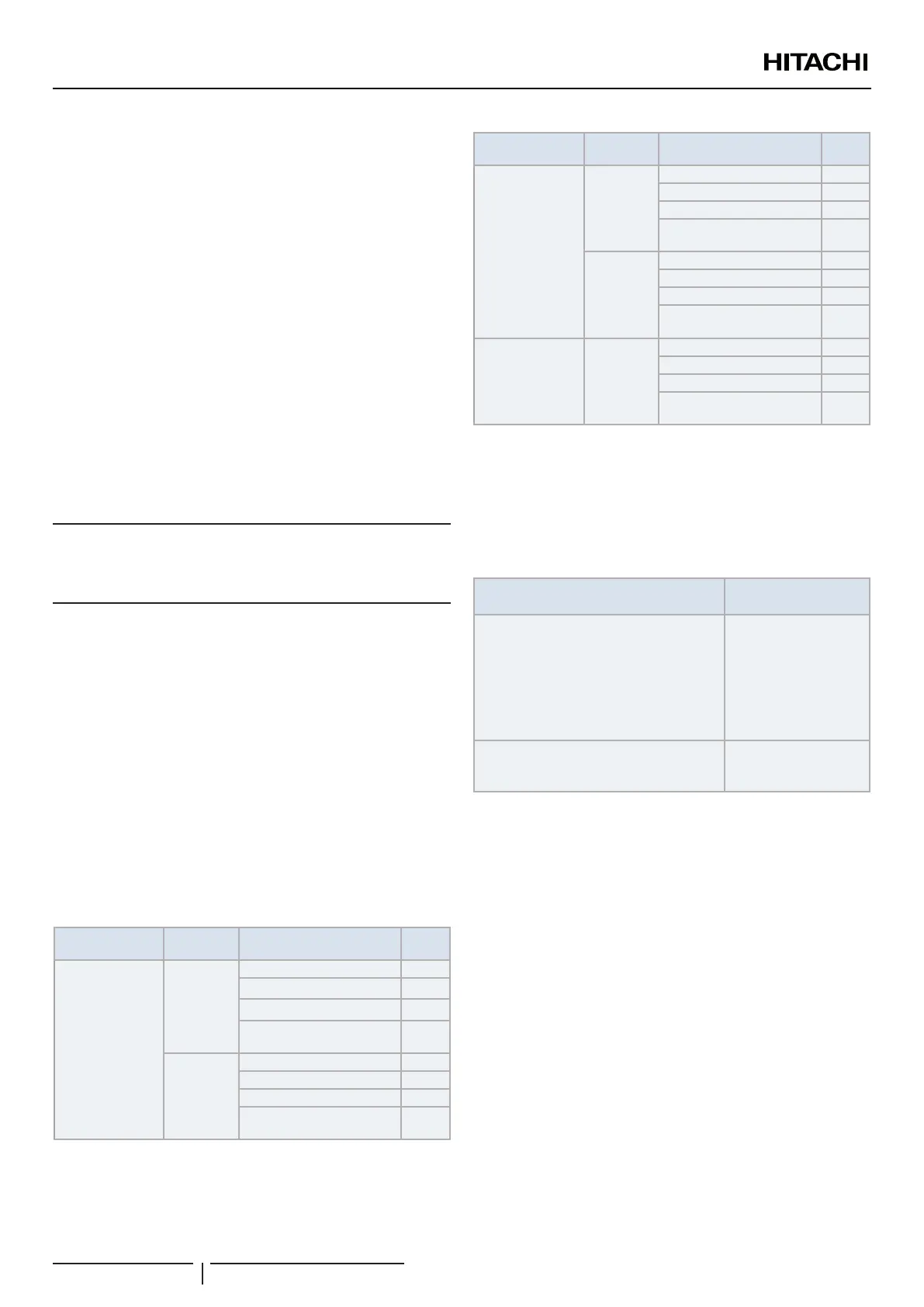

• The status of Harmonics for each model, regarding compliance

with EN 61000-3-2 and EN 61000-3-12, is as follows:

Status regarding compliance with

EN 61000-3-2 and EN 61000-3-12

Models

Equipment complying with EN 61000-3-2

RWM-2.0R1E

RWM-2.5R1E

RWM-3.0R1E

RWM-4.0N1E (3N~)

RWM-5.0N1E (3N~)

RWM-6.0N1E (3N~)

RWM-8.0N1E

RWM-10.0N1E

Equipment complying with EN 61000-3-12

RWM-4.0N1E (1~)

RWM-5.0N1E (1~)

RWM-6.0N1E (1~)

• Check to ensure that existing installation (mains power

switches, circuit breakers, wires, connectors and wire

terminals) already complies with the national and local

regulations.

• The use of the DHW tank heater is disabled as setting. If it

is desired to enable the DHW tank heater operation during

normal indoor unit operation, adjust the DSW4 pin 3 of the

PCB1 to the ON position and use the adequate protections.

Refer to the section “5.6 Setting of DIP switches and RSW

switches” for the detailed information.

Electrical and control settings

PMML0574 rev.1 - 09/2021

12

Loading...

Loading...