SOLID STATE ECONOMIZER SYSTEM

63-2484—1

7

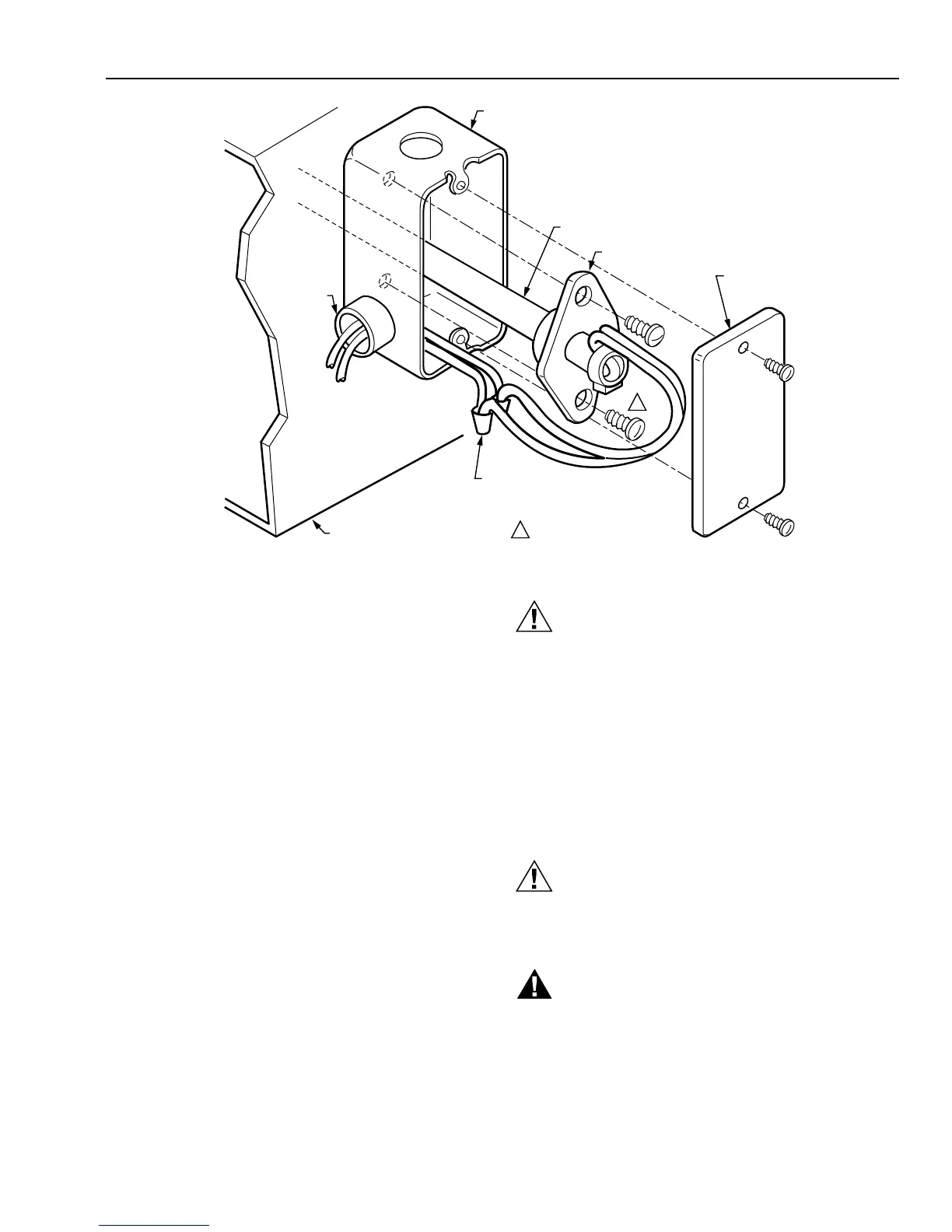

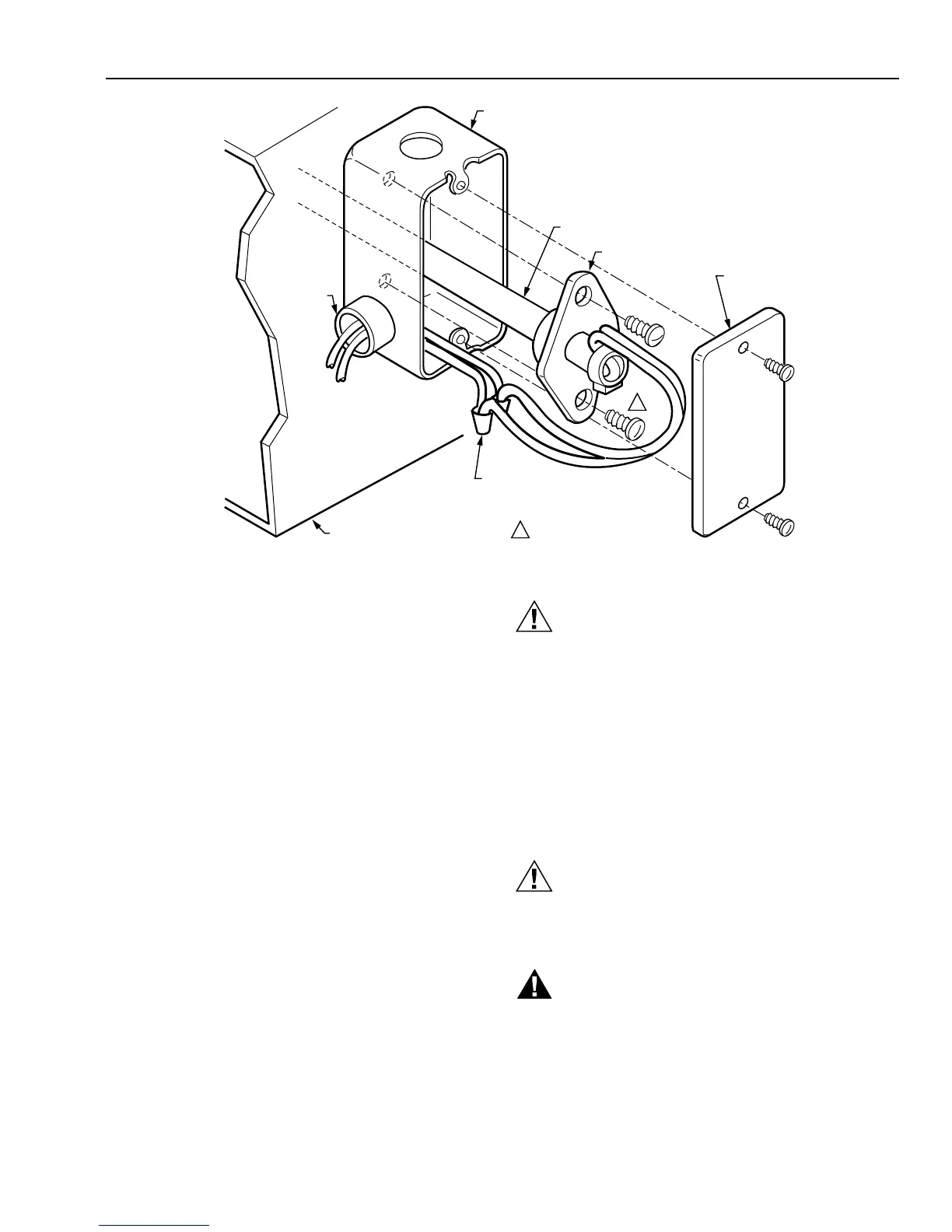

SCREWS NOT PROVIDED.1

1

SENSOR PROBE

SYSTEM DUCT OR PLENUM

FLANGE

STANDARD 2 X 4 (51 X 102)

OUTLET BOX (OPTIONAL)

CONNECTOR

AND

LOCKNUT

BLANK

FACEPLATE

(OPTIONAL)

TO APPROPRIATE

SYSTEM COMPONENTS

(SEE WIRING DIAGRAM)

SENSOR WIRES WITH 2

SOLDERLESS CONNECTORS

M9088

Fig. 8. Mounting C7046C Discharge Air Temperature Sensor in junction box.

Wiring

IMPORTANT

Failure to follow these wiring practices can introduce

electrical interference (noise) that can cause erratic

system operation:

a. Keep wiring at least one foot away from large

inductive loads such as motors, line starters,

lighting ballasts, and large power distribution

panels.

b. Shielded cable is required in installations where

these guidelines cannot be met.

c. Ground shield only to grounded controller case.

IMPORTANT

Minimize erratic temperature readings from a

sensor to assure proper operation by following

these wiring practices:

a. Route temperature sensor wiring away from

building power wiring, control contactors and

light dimming circuits, electric motors and

welding equipment.

b. Make good physical wiring connections to assure

good electrical connections.

c. Make sure that building earth ground connections

are not intermittent or missing.

d. Mount sensor only in recommended environment.

e. Use shielded cable to reduce interference if

rerouting of sensor wiring is not possible.

CAUTION

CAN CAUSE ELECTRICAL SHOCK OR

EQUIPMENT DAMAGE.

Disconnect the power supply before connecting the

wiring.

Make sure wiring complies with applicable local

codes, ordinances and regulations.

Connect low voltage wiring from the sensor to the appropriate

system component terminals using solderless connectors as

shown in Fig. 7 and 8.

M7415A, M8405A Damper Actuators

CAUTION

CAN CAUSE ELECTRICAL SHOCK OR

EQUIPMENT DAMAGE.

Disconnect power supply before connecting wiring.

WARNING

CAN CAUSE PERSONAL INJURY.

Do not remove end covers from actuator; spring

return assembly can release to harm installer.

Loading...

Loading...