Loading...

Loading...

Do you have a question about the Honeywell CLMERL8N and is the answer not in the manual?

| Brand | Honeywell |

|---|---|

| Model | CLMERL8N |

| Category | Controller |

| Language | English |

Important recommendations and precautions to follow before powering up the unit.

Information on the various communication ports available on the controller.

Safety precautions and general information for connecting the controller's power supply.

Lists of compatible actuators and sensors for system optimization and control.

Details on Blinds, Light, and other function blocks for implementing control logic.

Methods for manual blinds positioning and handling application command inputs.

Managing emergency inputs and interpreting feedback signals from function blocks.

Features and operation of the light function block, including manual control methods.

Using application commands, manual inputs, and sensors for lighting control logic.

How the controller automatically assigns MAC addresses on a BACnet MS/TP bus.

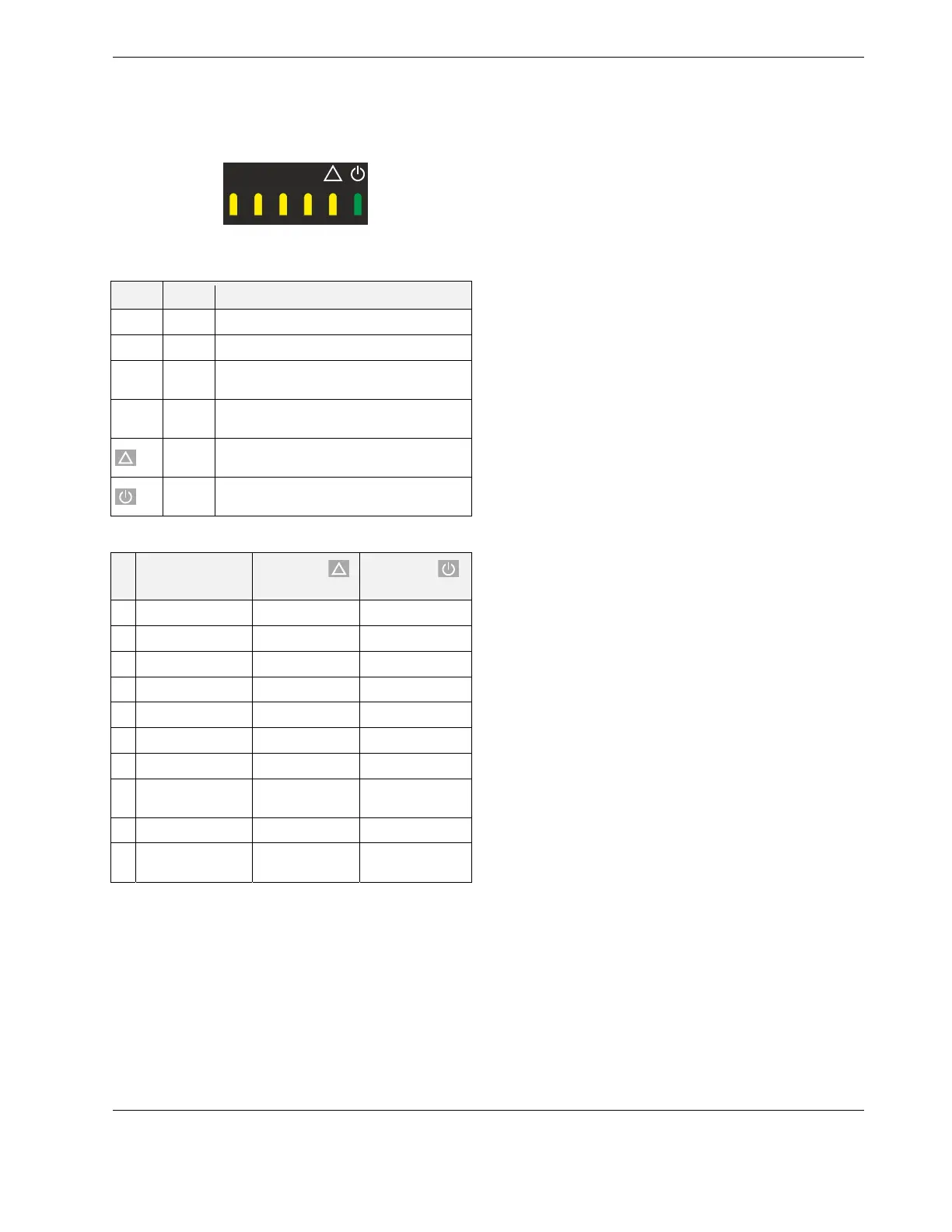

How to use the service button for resets, firmware updates, and operational functions.

Information on BACnet MS/TP interface, considerations, and WiFi adapter connection.

Details on the non-isolated RS485 interface for Modbus master communication.

Maximum permissible current outputs for power terminals to prevent device damage.

Steps and advice for diagnosing and resolving common controller issues.