MERLIN NX ROOM CONTROLLER – INSTALLATION & COMMISSIONING INSTRUCTIONS

EN1Z-1035GE51 R0420 18

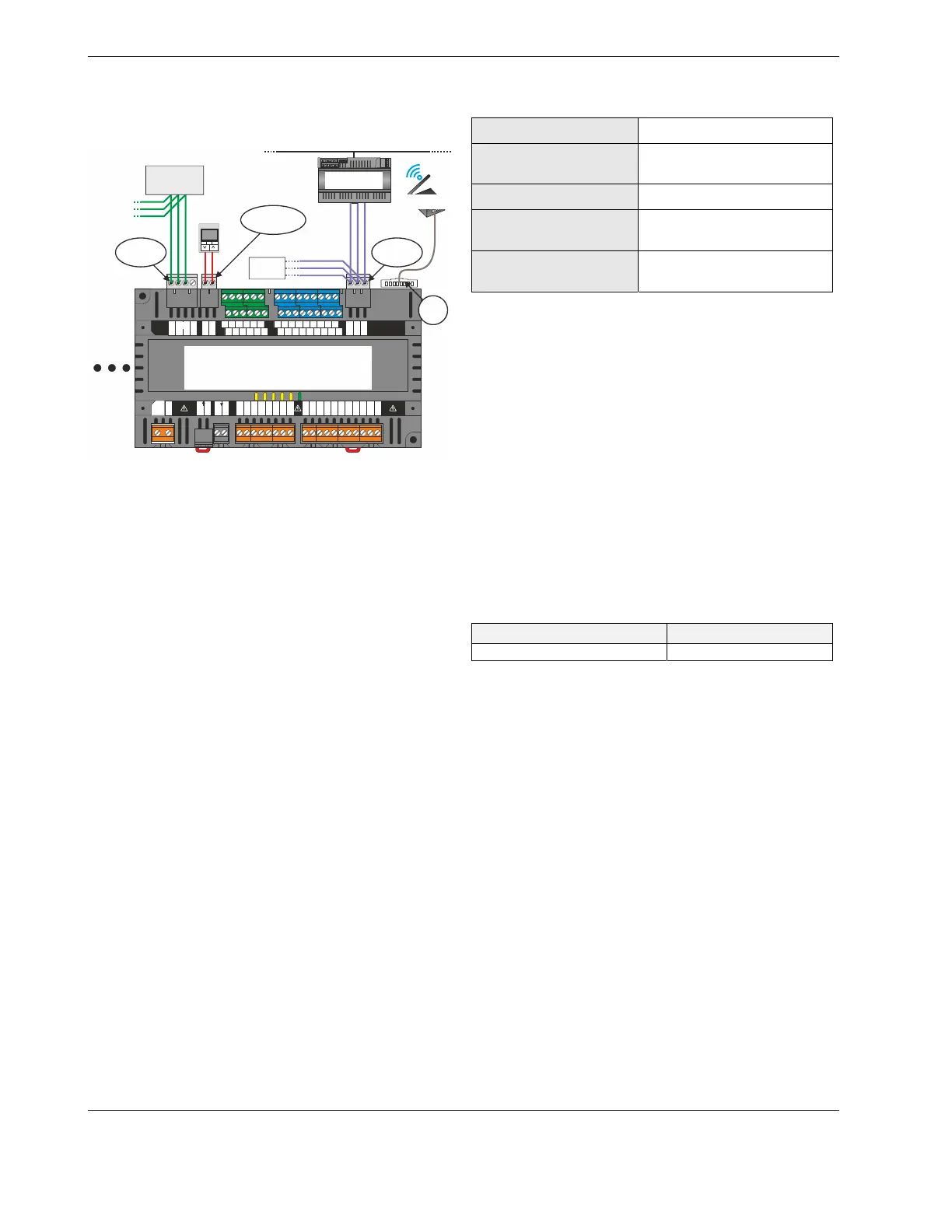

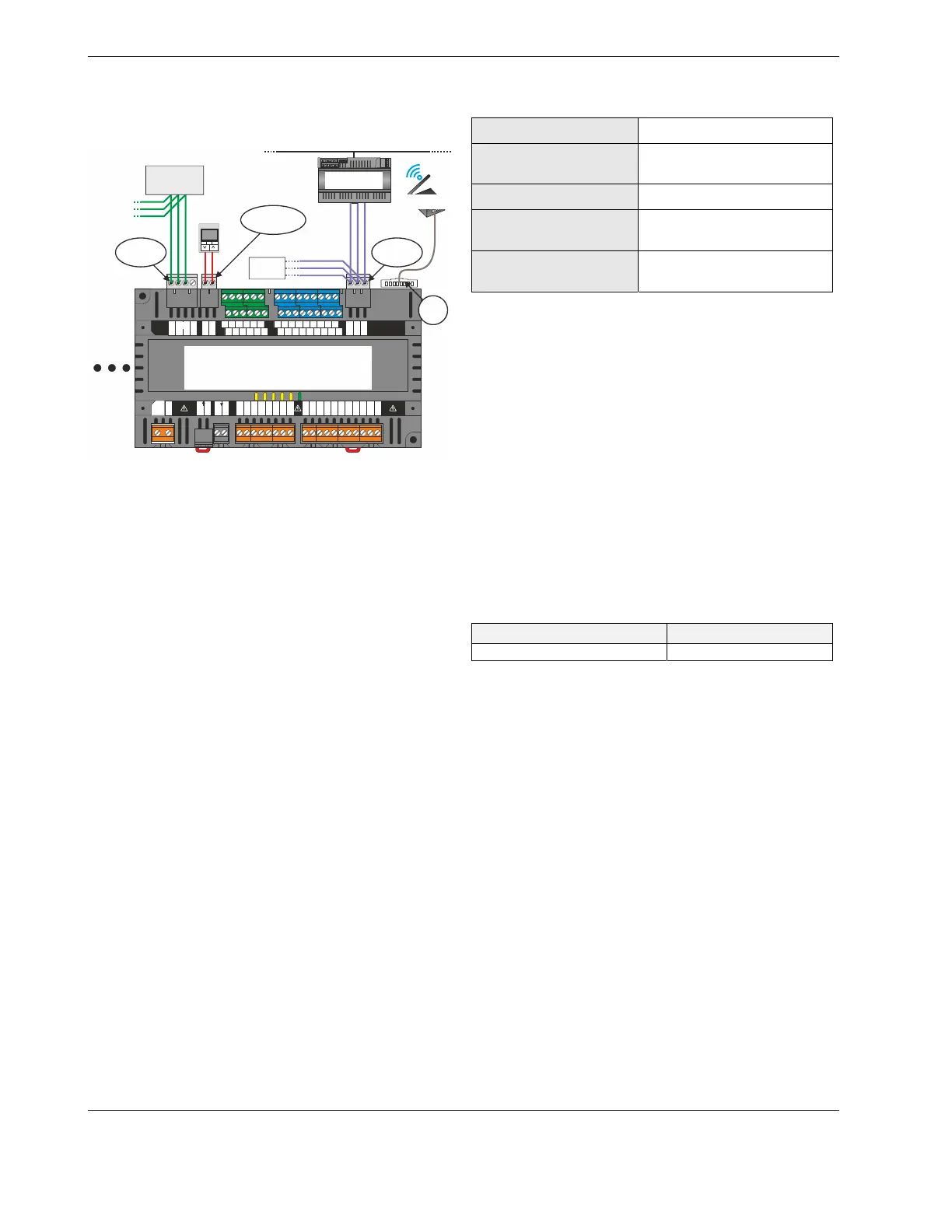

COMMUNICATION INTERFACES

Overview of Interfaces

BACnet IPTCP/IP

BACnet MS/TP

MODBUS

CLCM

TR40x/TR42x

2

N

3

24V~

7

TN

8

T~

9

T01

10

TN

11

T02

12

T03

13

TN

14

T04

15

RC4

16

RO4

17

IN4

18

RN

19

RN

20

IN1

21

RO1

22

IN2

23

RO2

24

IN3

25

RO3

4

24V0

5

24V~

6

24V0

1

L

26

C2+ GND

28

24V~

2927

C2-

WM1

30

WM2

31

3832

AO1

34

AO2

36

AO3

AO4

40

AO5

42

AO6

33

GND

35

24V~

37

GND

39

24V~

41

GND

43

24V~

44

24V~

46

GND

48

UI2

50

UI3

52

GND

54

UI6

56

UI7

58

GND

60

UI10

45

LED

47

UI1

49

GND

51

UI4

53

UI5

55

GND

57

UI8

59

UI9

61

GND

62

C1+

63

C1- GND

64

BACnet MS/TP

SERVICE

RS485-1

INTERF.

RS485-2

INTERF.

SYLK BUS

INTERFACE

PLANT

CONTROLLER

e.g., LIGHT I/O or WALL MODULE

RxxN #62

(MODBUS MASTER)

RxxN #61

(SLAVE)

PREVIOUS

MODBUS

SLAVE

RJ45

BACnet WiFi

ADAPTER

MODBUS

SLAVE

24V0

(GND)

Fig. 23. System overview (example: RLxN)

The TIA/EIA-485 Standard

According to the TIA/EIA-485 standard ("Electrical Charac-

teristics of Generators and Receivers for Use in Balanced

Digital Multipoint Systems"), only one driver communicating

via an RS485 interface may transmit data at a time. Further,

according to U.L. requirements, each RS485 interface may be

loaded with a max. of 32 unit loads. E.g., Honeywell /

CentraLine devices have as little as ¼ unit load each, so that

up to 128 devices can be connected.

BACnet and Modbus connections to the RS485 interfaces

must comply with the aforementioned TIA/EIA-485 standard.

Thus, it is recommended that each end of every bus be

equipped with a termination resistor (not included in ship-

ment) having a resistance equal to the cable impedance

(120 Ω; the wattage should be in the range of 0.25 – 0.5 W).

RS485 systems frequently lack a separate signal ground wire.

However, the laws of physics still require that a solid ground

connection be provided for in order to ensure error-free

communication between drivers and receivers – unless all of

the devices are electrically isolated and no earth grounding

exists.

IMPORTANT

A separate signal ground wire must be used. Failing to

obey this requirement can lead to unpredictable

behavior if other electrically non-isolated devices are

connected and the potential difference is too high.

TIA-EIA 485 Cable Specifications

The following cable specification is valid for all EIA 485 buses

(incl. Modbus and BACnet MS/TP).

Table 9. TIA/EIA 485 cable specifications

max. length

1200 meters (9.6 – 78.8 kbps)*

cable type

twisted pair, shielded (foil or

braided shields are acceptable)

charac. impedance

100…130 Ω

distributed capacitance

between conductors

Less than 100 pF per meter

(30 pF per foot)

distributed cap. between

conductors and shield

Less than 200 pF per meter

(60 pF per foot)

*A higher communication rate (necessitating a shorter max.

length) is possible for Modbus. See section "Modbus

Considerations" on pg. 20.

The following cables fulfill this requirement:

• AWG 18;

• shielded, twisted pair cable J-Y-(St)-Y 4 x 2 x 0.8;

• CAT 5,6,7 cable (use only one single pair for one bus);

• Belden 9842 or 9842NH.

BACnet MS/TP Interface

The controller features an isolated RS485 interface (RS485-

1) suitable for BACnet MS/TP communication:

▪ RLxN: terminals 62, 63, and 64;

▪ RSxN: terminals 40, 41, and 42.

The terminal block containing it is gray. The cable length

affects the communication rate. Table 10 provides a few

examples.

Table 10. Baud rate vs. max. cable length

baud rate max. cable length (L)

9.6, 19.2, 38.4, 57.6, and 76.8 kbps 1200 m

The controller supports auto-baud rate adaption for BACnet

MS/TP communication at all of the aforementioned baud

rates (default: 38.4 kbps).

For information on wire gauge, max. permissible cable length,

possible shielding and grounding requirements, and the max.

number of devices which can be connected to a bus, refer to

standard TIA/EIA-485.

BACnet MS/TP Considerations

The controller communicates via its isolated RS482-1 inter-

face with other BACnet MS/TP-capable devices (e.g., other

room controllers or plant controllers like the EAGLE / Excel

Web II or EAGLEHAWK NX). In doing so, the following con-

siderations should be taken into account.

▪ Max. BACnet MS/TP bus length (= "L" in Fig. 24): See

Table 10.

▪ Twisted-pair cable, e.g.:

- AWG 18;

- J-Y-(St)-Y 4 x 2 x 0.8;

- CAT 5,6,7 cable – use only one single pair for one

bus;

- Belden 9842 or 9842NH);

and daisy-chain topology.

Loading...

Loading...