MPD Operating Manual

13

2. Installation

WARNING

The Code of Practice regarding ‘Selection, Installation and Maintenance of

Electrical Apparatus for use in Potentially Explosive Atmospheres’ must be

complied with at all times. Refer to the appropriate local and/or national regulations

relative to the installation site. Elsewhere the appropriate local and/or national

regulations should be used.

CAUTIONS

The catalytic detector element is resistant to catalyst poisons, however, abnormally

high concentrations of halogenated hydrocarbons, vapors of heavy metals or

compounds, some silicone compounds and sulfur compounds may cause loss of

sensitivity.

The MPD must never be used in conditions where there is insufficient oxygen to

totally oxidize the combustible gas. For most combustible gases, an oxygen level

of at least 15% is sufficient.

The sintered disc on the sensor assembly must be kept free from contaminants;

i.e. oil and dirt.

2.1 Unpacking

On receipt the equipment must be carefully unpacked, observing any instructions

printed on the packaging, and the contents checked for deciencies and transit

damage.

2.2 Sensor Orientation

The sensor must be installed with the Sensor facing downwards. For MPD-BT-

IC1 and MPD-UT-IC1 performance approval, the supplied SPXCDWP weather

protector must be installed in order to meet published performance standards. In

environments requiring IP66 protection, the SPXCDWP must be tted.

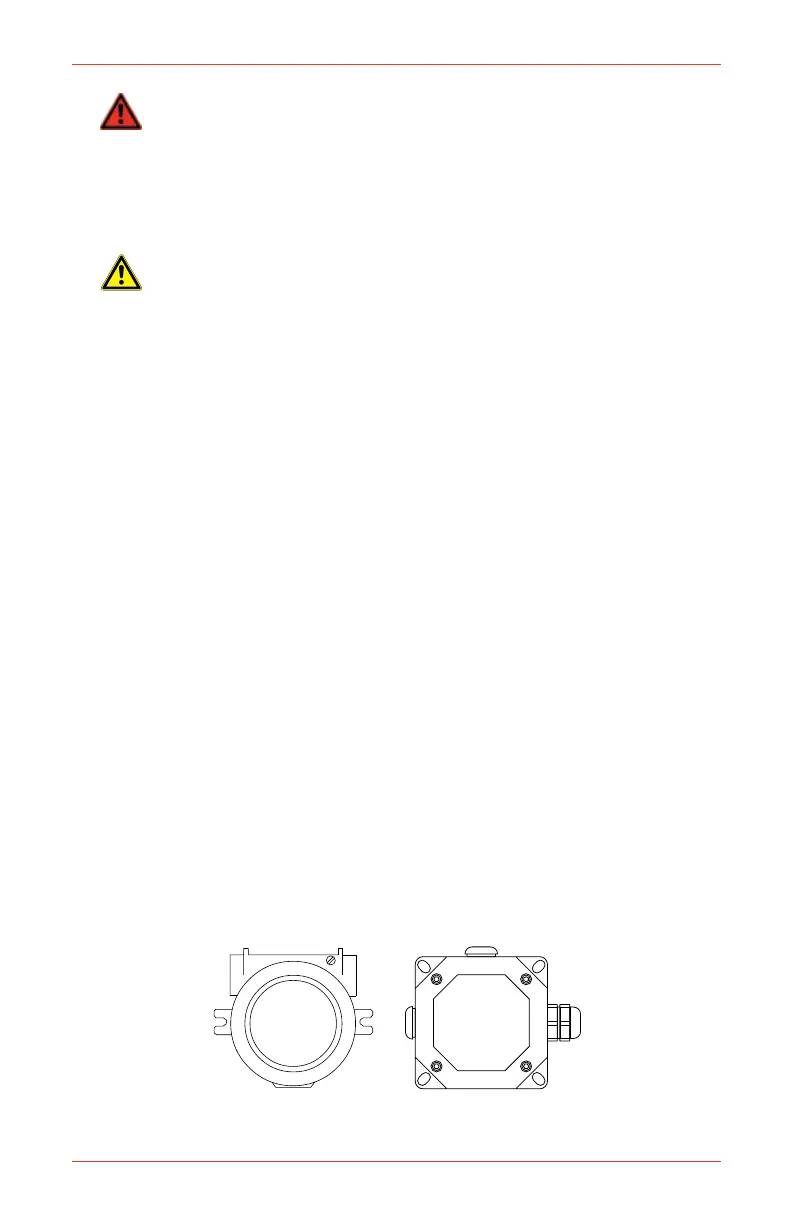

2.3 MPD Remote Mount

The MPD can be remote mounted using an approved junction box and

interconnecting conduit or cabling. The Junction Box and installation must be in

compliance with all local requirements for the area in which the unit is installed.

• The MPB UT versions must be installed a minimum of 5 1/4 turns into the

Junction box or Transmitter to maintain approval rating.

• The MPD Leads are factory sealed, which relieves the requirement for a

pour tting between the junction box and sensor.

UL/CSA Aluminum Junction Box

2441-0022

ATEX/IEC Junction Box

00780-A-0100

Figure 8. Terminal Housings

Loading...

Loading...