S8600B,C,H,M; S8610B,C,H,M; S8670D,E,J,K INTERMITTENT PILOT GAS IGNITION CONTROL

บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

POWER TO

MODULE? (24 V

NOMINAL)

SPARK

ACROSS IGNITER/

SENSOR

GAP?

REPEAT PROCEDURE UNTIL

TROUBLE FREE OPERATION

IS OBTAINED.

PULL IGNITION LEAD AND

CHECK SPARK AT MODULE.

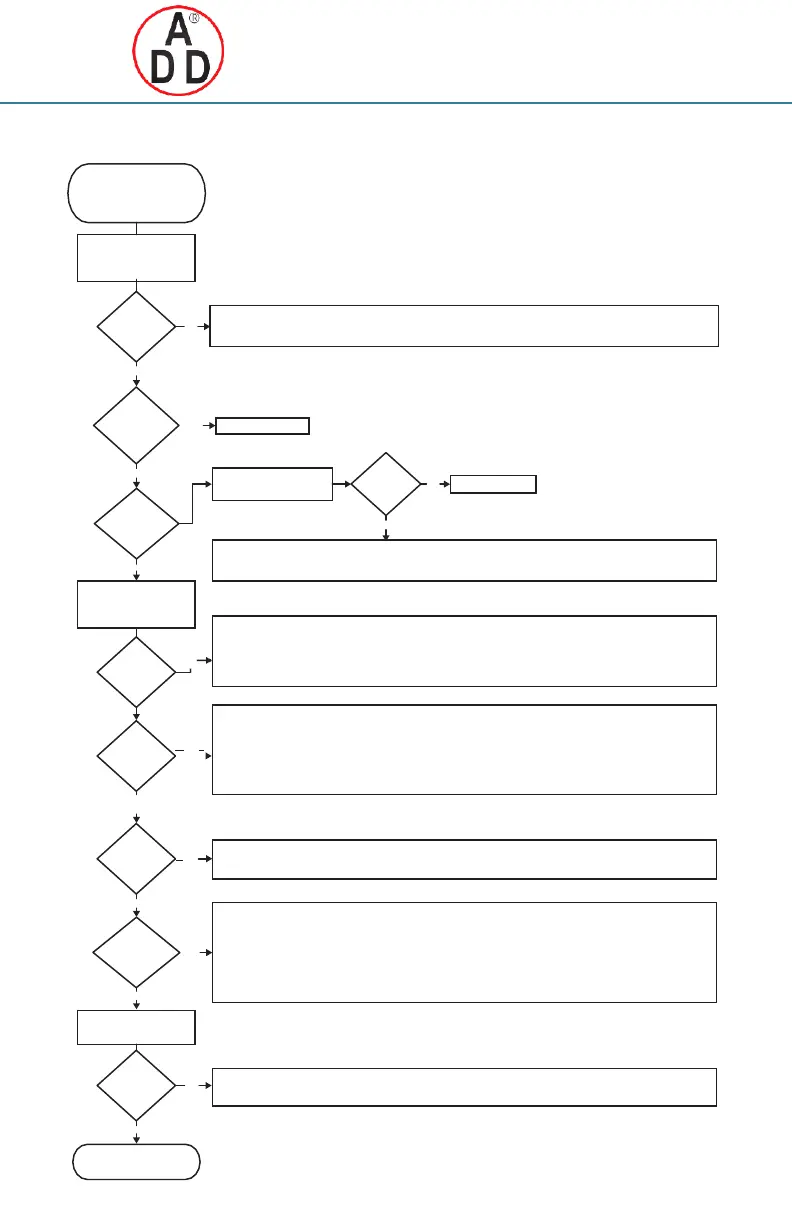

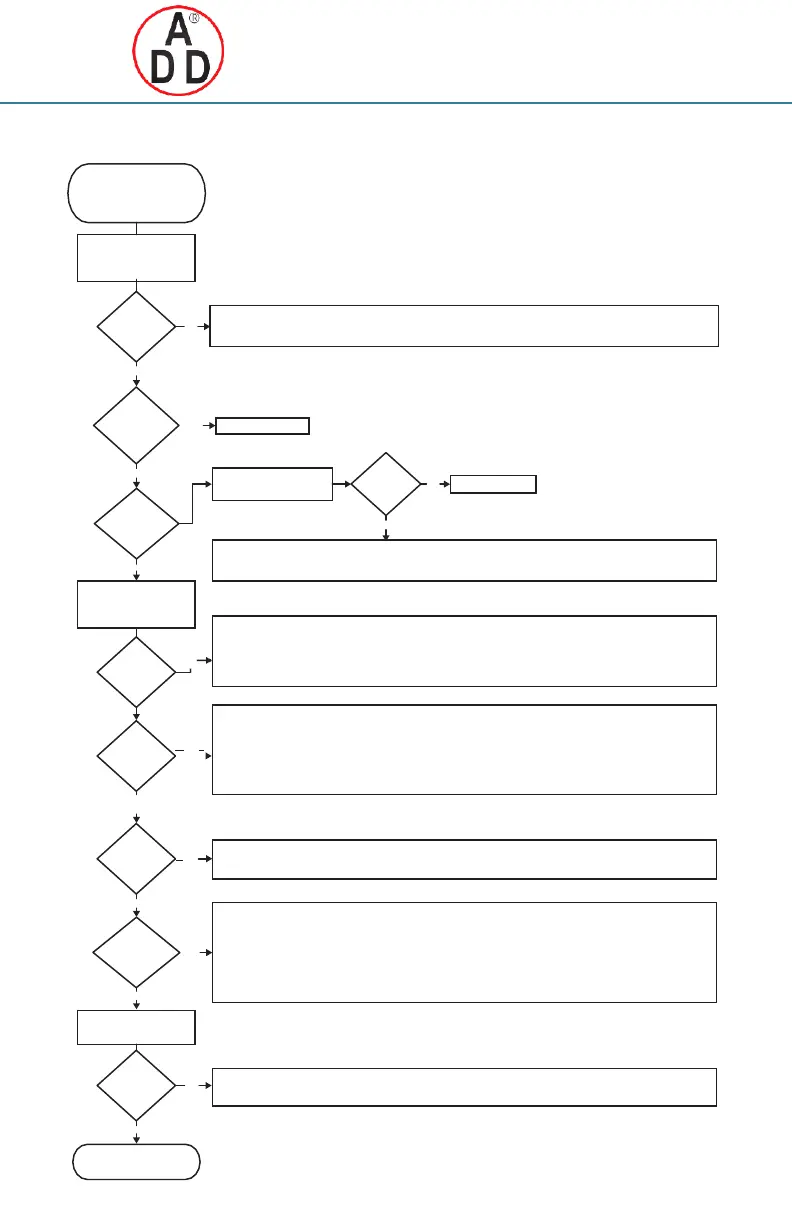

Troubleshooting Guide

Refer to the following guide for troubleshooting (Fig. 14).

NOTE: “CALL FOR HEAT” 24 VAC SUPPLY IS CONNECTED TO THE 24 V TERMINAL ON THE CONTROL.

NO

YES

30 SECOND

PREPURGE

NO

DELAY?(S8670

ONLY)

YES

NO

YES

YES

SPARK

STOPS WHEN

PILOT IS

NO

LIT?

YES

NO

YES

SYSTEM

RUNS UNTIL “CALL

NO

FOR HEAT”

ENDS?

YES

YES

Fig. 14. Troubleshooting Guide.

M29921

TURN GAS SUPPLY OFF.

TURN THERMOSTAT

(CONTROLLER)TO “CALL

FOR HEAT.”

TURN GAS SUPPLY ON AND

RECYCLE “CALL FOR HEAT.”

CHECK FOR PROPER THERMOSTAT (CONTROLLER) OPERATION.

REMOVE MV LEAD AT MODULE. IF VALVE CLOSES, RECHECK TEMPERATURE CONTROLLER AND WIRING. IF NOT, REPLACE

GAS CONTROL.

START

BEFORE TROUBLESHOOTING,

FAMILIARIZE YOURSELF WITH THE

STARTUP AND CHECKOUT

PROCEDURES.

CHECK LINE VOLTAGE POWER, LOW VOLTAGE TRANSFORMER, LIMIT CONTROLLER, THERMOSTAT (CONTROLLER), AND WIRING. ALSO,

CHECK AIR PROVING SWITCH ON COMBUSTION AIR BLOWER SYSTEM (IF USED) AND THAT THE VENT DAMPER END SWITCH (IF USED) IS

MADE.

CHECK IGNITION CABLE, GROUND WIRING, CERAMIC INSULATOR, AND SPARK GAP AND CORRECT.

CHECK BOOT OF THE IGNITION CABLE FOR SIGNS OF MELTING OR BUCKLING. TAKE PROTECTIVE ACTION TO SHIELD CABLE

AND BOOT FROM EXCESSIVE TEMPERATURES.

CHECK THAT ALL MANUAL GAS VALVES ARE OPEN, SUPPLY TUBING AND PRESSURES ARE GOOD, AND PILOT BURNER

ORIFICE IS NOT BLOCKED (PILOT GAS FLOWING).

CHECK ELECTRICAL CONNECTIONS BETWEEN MODULE AND PILOT OPERATOR ON GAS CONTROL.

CHECK FOR 24 VAC ACROSS PV-MV/PV TERMINALS ON MODULE. IF VOLTAGE IS OKAY, REPLACE GAS CONTROL. IF NOT,

REPLACE MODULE.

NOTE: IT MAY BE NECESSARY TO RECYCLE THE “CALL FOR HEAT” MORE THAN ONCE TO CLEAR THE PILOT SUPPLY TUBES OF AIR.

NOTE: IF CONTROL GOES INTO LOCKOUT OR RETRY DELAY, RESET THE “CALL FOR HEAT.”

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

CLEAN FLAME ROD.

CHECK ELECTRICAL CONNECTIONS BETWEEN FLAME ROD AND MODULE.

CHECK FOR CRACKED CERAMIC FLAME ROD INSULATOR.

CHECK THAT PILOT FLAME COVERS FLAME ROD AND IS STEADY AND BLUE.

ADJUST PILOT FLAME.

IF PROBLEM PERSISTS, REPLACE MODULE.

CHECK FOR 24 VAC ACROSS PV-MV/PV TERMINALS ON MODULE. IF NO VOLTAGE, REPLACE MODULE.

CHECK ELECTRICAL CONNECTIONS BETWEEN MODULE AND GAS CONTROL INCLUDING SAFETY CONTROLS WIRED IN THE CIRCUIT. IF

OKAY, REPLACE GAS CONTROL.

NOTE: IF CONTROL GOES INTO LOCKOUT OR RETRY DELAY, RESET THE “CALL FOR HEAT.”

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

NOTE: IF GROUND IS POOR OR ERRATIC, SHUTDOWNS MAY OCCUR OCCASIONALLY EVEN THOUGH OPERATION IS NORMAL

AT THE TIME OF CHECKOUT.

CHECK THAT PILOT FLAME COVERS FLAME ROD AND IS STEADY AND BLUE. PILOT FLAME MUST NOT BE MOVING AROUND DUE TO

OUTSIDE AIR FLOWS, ETC.

ADJUST PILOT FLAME. CHECK GAS PRESSURE MEETS APPLIANCE SPECIFICATIONS WHILE APPLIANCE MAIN BURNER ON AND ALL

OTHER GAS APPLIANCES ON THE SUPPLY ARE OPERATING AT FULL RATE.

IF CHECKS ARE OKAY, REPLACE MODULE.

Loading...

Loading...