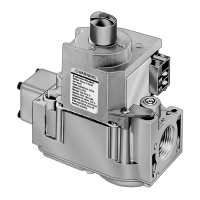

Do you have a question about the Honeywell VR8305 and is the answer not in the manual?

| Brand | Honeywell |

|---|---|

| Model | VR8305 |

| Category | Control Unit |

| Language | English |

Details product capacity based on inlet/outlet size and pressure drop for natural gas.

Covers body pattern, available inlet/outlet sizes, and electrical ratings for the gas control.

Covers critical safety warnings and cautions for installing the gas control.

Detailed instructions for converting the gas control between natural and LP gas.

Steps for installing adapters, choosing a location, and installing piping for the gas control.

Procedures for mounting the gas control, connecting gas piping, and using wrenches.

Illustrates wiring connections for S87 Direct Ignition and S89C Direct Ignition systems.

Important notes on power supply, wiring compliance, and heat anticipator adjustment.

Instructions for performing a gas leak test on pipe connections and the gas control.

Procedures for checking and adjusting gas input to the main burner using a meter or manometer.

Guidance on adjusting the pressure regulator to match appliance specifications.

Steps to test the safety shutdown mechanism of the gas control system.

Importance of regular maintenance, factors affecting frequency, and when to replace the control.

Guidance on diagnosing and resolving issues like the main burner not coming on.

Critical safety warnings for homeowners regarding gas appliance operation.

Instructions for operating the appliance and performing vacation or complete shutdown.

Loading...

Loading...