13

Operations

The air band required adjustment to 1.8” opening and

fuel pressure lowered to 150 PSI for a high altitude

adjustment for both heat input adjustments and

combustion air intake with the same fuel type.

Fuel Pressure Adjustment:

To adjust fuel pressure, First install a pressure gage

into the port just after the pump fuel exit. Turn the

adjusting screw (located at the regulator port)

clockwise to increase, and counterclockwise to

decrease. Do not exceed 200 psi or lower the pressure

below 130 PSI, when checked at the post-pump

pressure port.

The fuel pressure may need to be adjusted due to

altitude. For every 500 ft altitude above sea level, the

boiling point of water goes down 1 °F. At high altitude

environments, this boiling point change may require

the heat input to be lowered so the water input does

not turn to steam earlier than at the factory settings and

activate the pressure sensors and pressure relief

equipment when the unit is operated and much higher

altitudes from factory settings or local dealer site

settings. Check with your dealer before making local

site fuel pressure adjustments.

Also, as ambient temperature changes seasonally, the

fuel temperature in the feed tank and air temperature

inlet can impact fuel flow. In more extreme

temperatures, this local-site adjustment may also

require different fuel nozzles for fuel inlet temperatures

that are at seasonal extremes (higher or lower) in

locations where the temperature changes are beyond

moderate temperatures of between 40°F and 90°F.

Colder temperatures will make for a thicker flow and

less fine a fuel spray while hotter temperatures will

make for a thinner flow a more fine spray with the same

nozzle. Consider alternate nozzle configurations from

the baseline factory-supplied nozzle for operating in

such temperature extremes if performance is not

meeting needs with air band and fuel pressure settings

alone.

NOTE: When changing fuel pump, a by-pass plug

must be installed in return line port or fuel pump will

not prime.

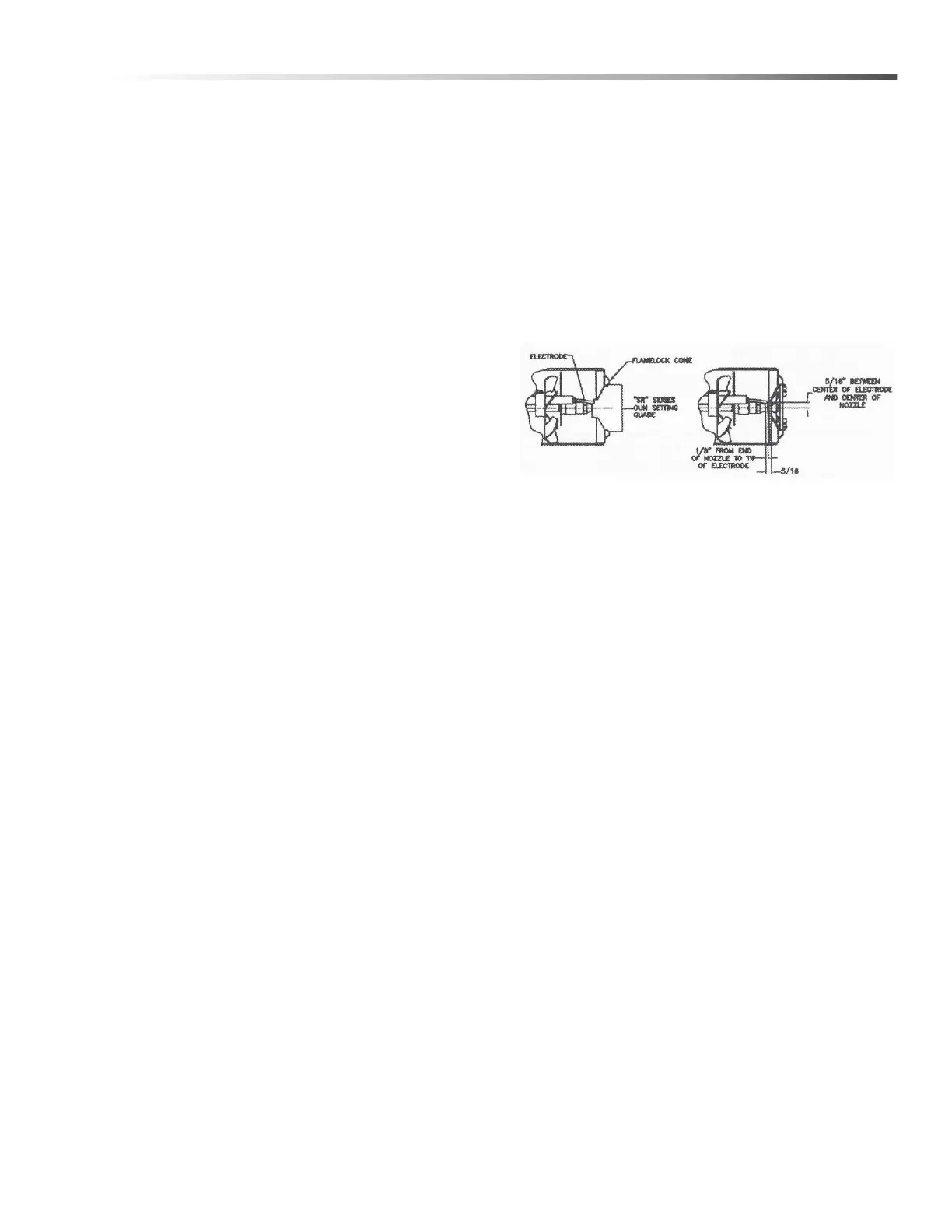

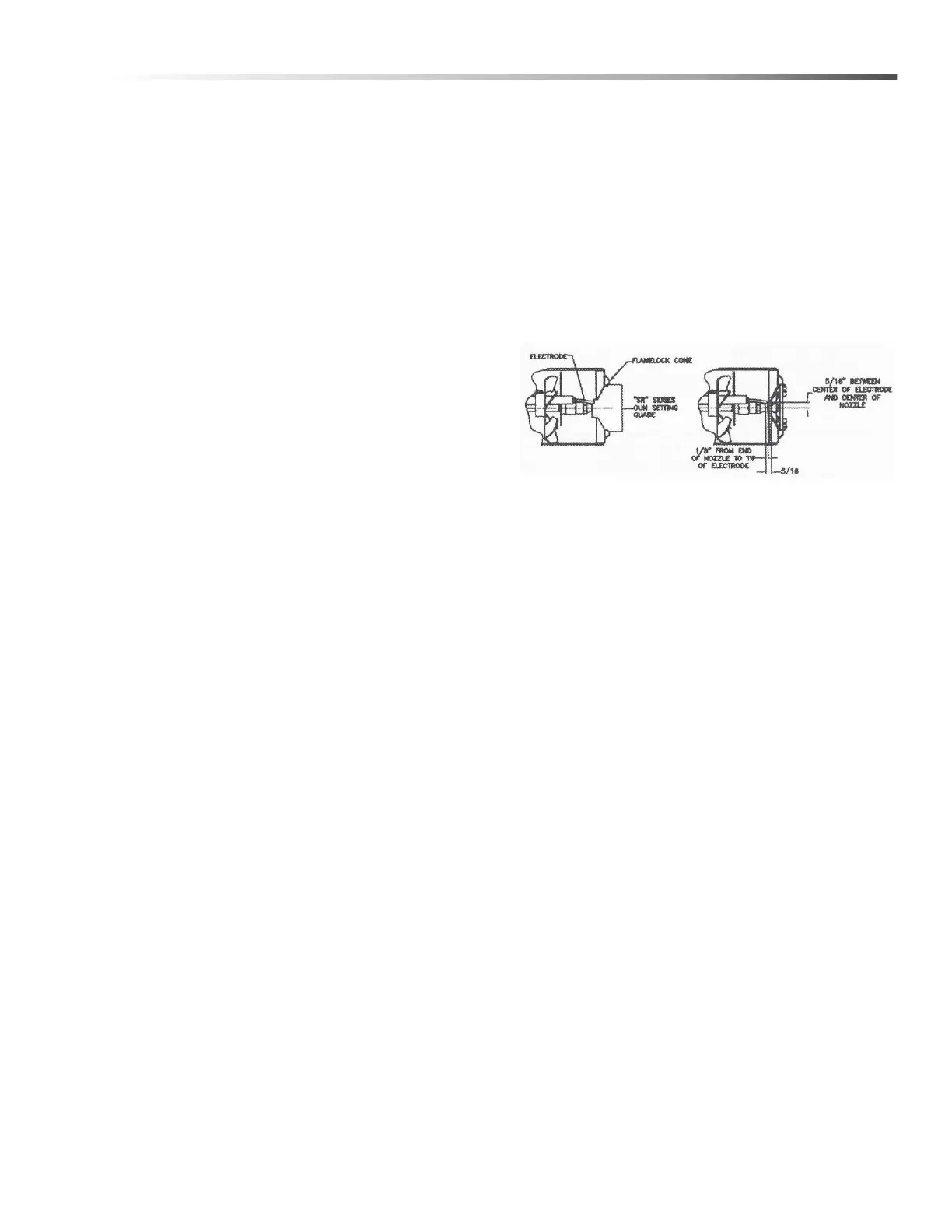

Electrode Setting

Burner Nozzle

Keep the tip free of surface deposits by wiping it with a

clean, solvent-saturated cloth, being careful not to plug

or enlarge the nozzle. For maximum efficiency, replace

the nozzle each season.

Gun Setting Instructions

For EHASR Only

SR-Series gage KNA Part

Number 8.717-379.0

CAUTION: If white smoke appears from burner

exhaust vent during start-up or operation, discon-

tinue use and readjust air bands.

ATTENTION: Si de la fumée blanche s'échappe de

l'évacuation du brûleur pendant le démarrage ou le

fonctionnement, cesser d'utiliser et réajuster les

bandes d'air.

NOTE: If a flue is installed, have a professional

serviceman adjust your burner for a #1 or #2 smoke

spot on the Bacharach scale.

Gasoline Engine

This gasoline engine is preset for operation at altitudes

below 3000 feet above sea level. If operated at higher

altitudes, it may be necessary to install a high altitude

main jet in the carburetor. Contact an authorized engine

sales and service center for details.

Water Supply

This machine is designed to be connected to a pressur-

ized (20 to 100 PSI) water supply, capable of maintaining

a minimum of 6.0 GPM. If it is necessary to use a gravity

feed water tank, the following plumbing modifications will

be required.

Hotsy Gas Belt Drive Series Operator’s Manual 8.931-236.0 - BD

Loading...

Loading...