lp-65 Rev. 1.6.15

9

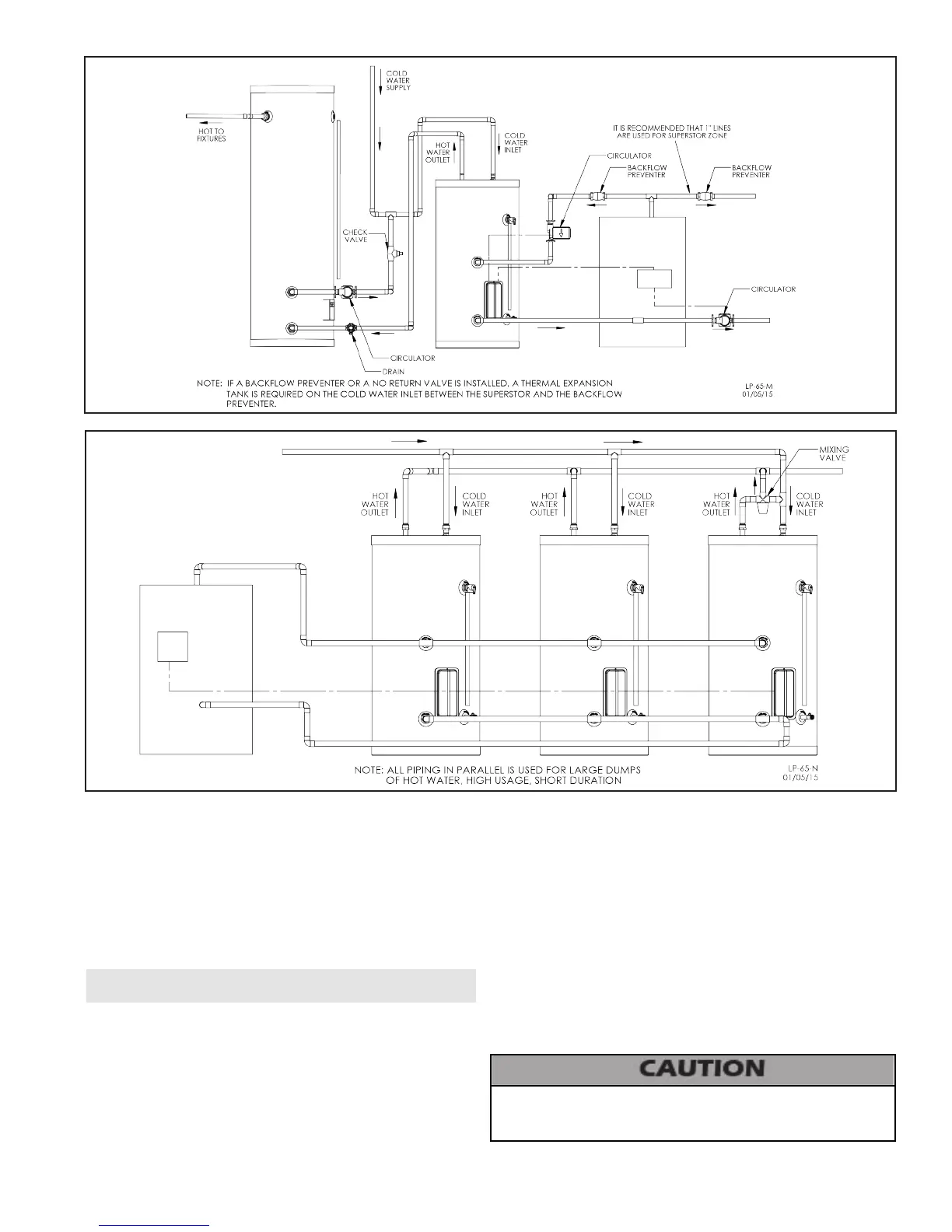

Figure 7 - Installation with Storage Tank

NOTES:

1. Minimum pipe size should match connection size. Upsize pipe accordingly if greater ow is required.

2. A thermal expansion tank suitable for potable water must be sized and installed within this piping system between the backow preventer

and the cold water inlet.

3. All circulators should have an integral ow check.

4. Drains and check valve between unit and storage tank will assist in purging air from system.

5. This drawing is meant to demonstrate system piping only. The installer is responsible for all equipment and detailing required by local codes.

In Massachusetts, you must install a vacuum relief valve per 248 CMR.

6. Mixing valve application is optional, but recommended to help prevent scalding.

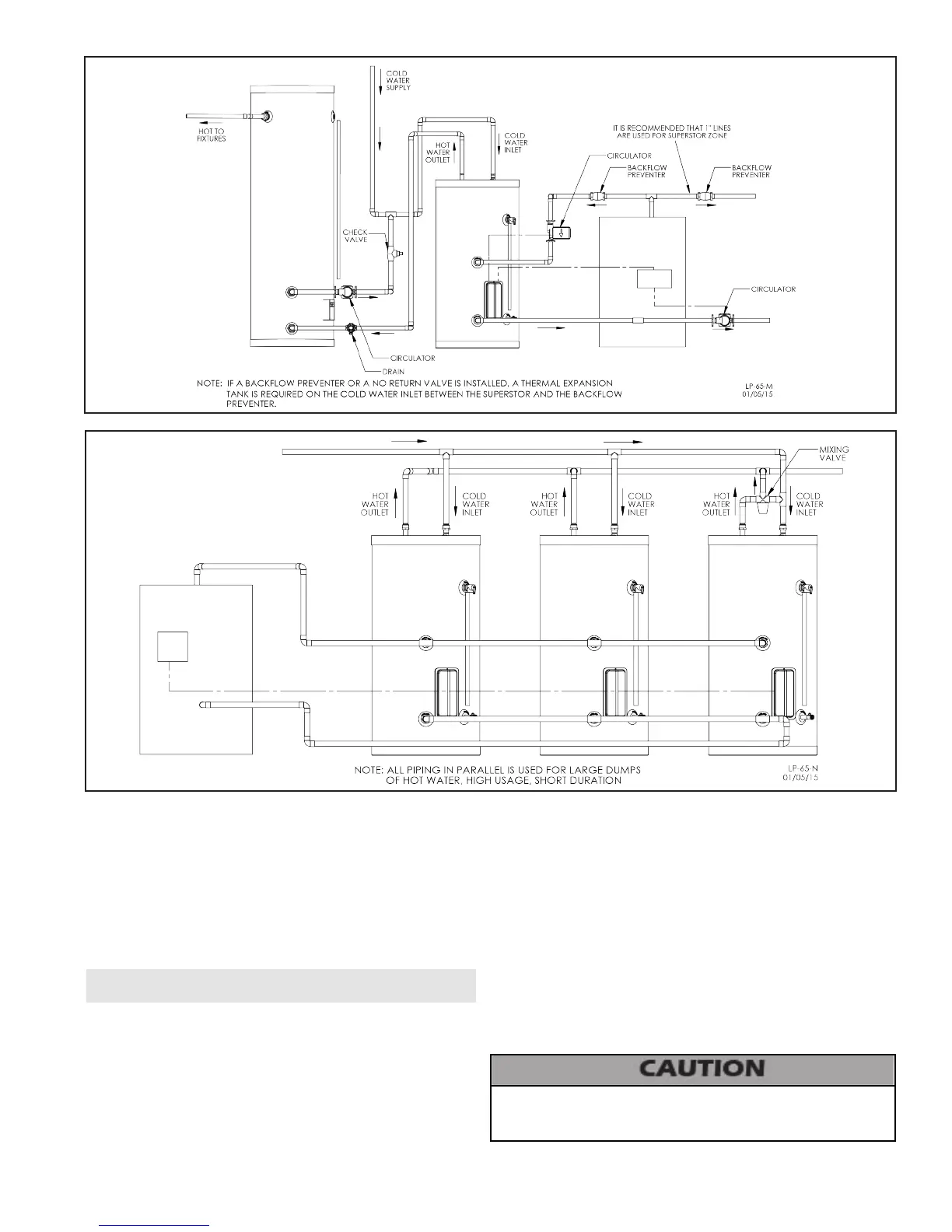

Figure 8 - Multiple Tank Installlation

Part 4 - Heater Control and Wiring

A. Control

A surface mounted control is provided and mounted inside

of the control access compartment. There is an insulation

blanket under the control access cover to ensure accurate

readings of water temperature. The control is factory set at

120

o

F for your safety (see scaled danger warning below). The

dierential is xed at 3 to 5

o

F (not adjustable).

B. Wiring

Wiring is to be done in accordance with all applicable local

When wiring the water heater and controls be sure to label

all wires to ease future maintenance. Wiring errors can cause

improper and dangerous operation.

and state codes. Turn o all power related to the boiler before

starting any wiring procedures.It is recommended that a

disconnect switch be installed between the boiler control and

the water heater.

Loading...

Loading...