English – 31

MAINTENANCE

Fine adjustment

When the machine has been ”run-in” the carburettor should be

finely adjusted. The fine adjustment should be carried out by a

qualified person. First adjust the L-jet, then the idling screw T

and then the H-jet.

The recommended engine speeds are as follows:

Conditions

• Before any adjustments are made the air filter should be

clean and the cylinder cover fitted. Adjusting the

carburettor while a dirty air filter is in use will result in a

leaner mixture next time the filter is cleaned. This can give

rise to serious engine damage.

• Carefully turn the L and H-jets clockwise as far as they will

go. Now turn the jets one turn anti-clockwise. The

carburettor is now set to H = 1 and L = 1.

• Now start the machine according to the starting

instructions and let it warm up for 10 minutes. CAUTION!

If the chain rotates while idling the T-screw must be

turned anti-clockwise until the chain stops.

• Place the machine on a flat surface so that the bar points

away from you and so that the bar and chain do not come

into contact with the surface or other objects.

Low speed jet L

Try to find the highest idle speed by turning the low speed jet

L clockwise then anti-clockwise. When the highest speed has

been found, turn the low speed jet L 1/4 turn anti-clockwise.

CAUTION! If the chain rotates while idling the T-screw

must be turned anti-clockwise until the chain stops.

Fine adjustment of the idle speed T

Adjust the idle speed using the idle adjustment screw T, if it is

necessary to readjust. First turn the idle adjustment screw T

clockwise until the cutting attachment starts to rotate. Then

turn the screw anticlockwise until the cutting attachment stops.

The idle speed is correctly adjusted when the engine will run

smoothly in every position. The idle speed should also be well

below the speed at which the cutting attachment starts to

rotate.

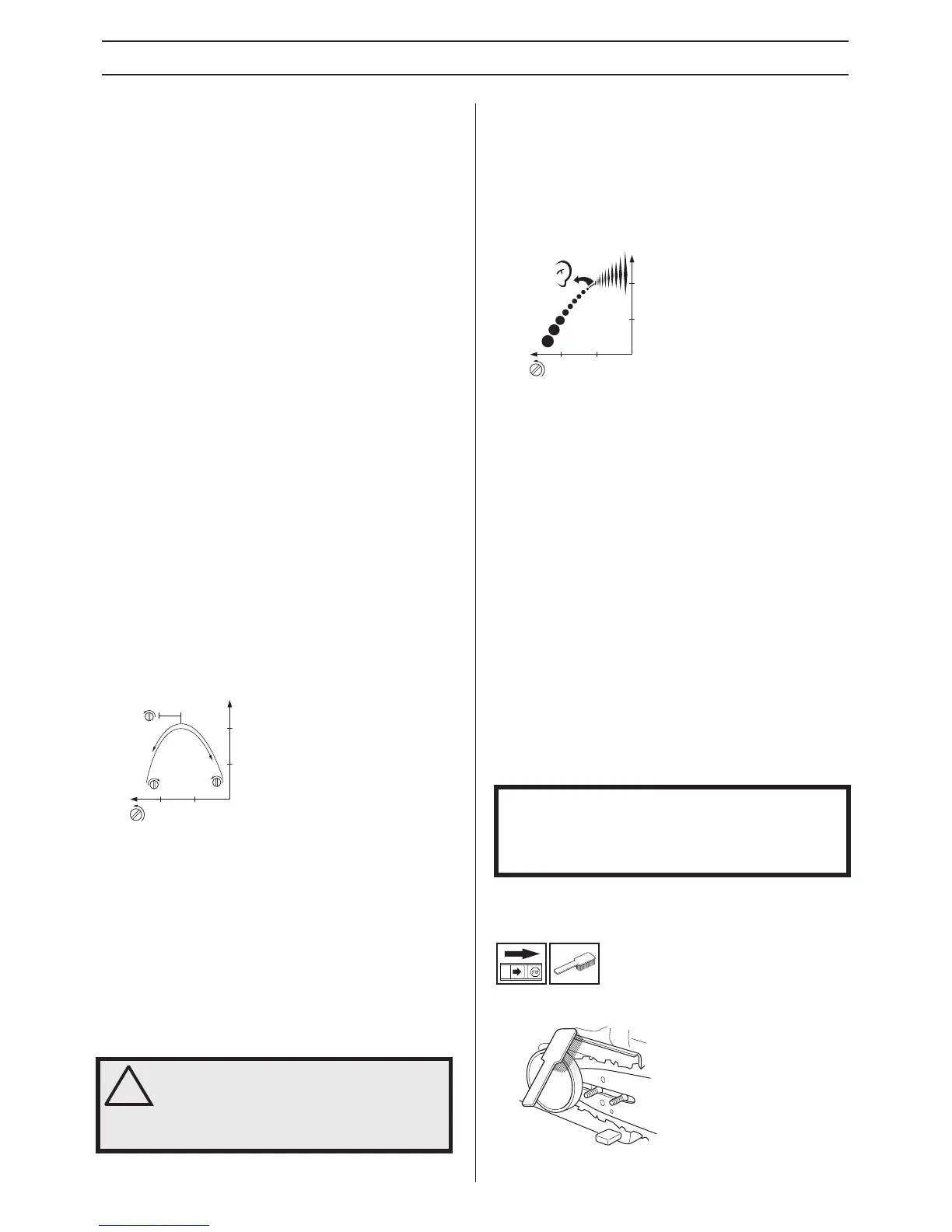

High speed jet H

•

The high speed jet H influences the power and engine speed of

the machine. If the high speed jet is set too rich (H-jet screwed

in too far) the machine will over-rev and this will damage the

engine. Run the machine at full throttle for about 10 seconds.

Then turn the H-jet 1/4 turn anti-clockwise. Run the machine at

full throttle for another 10 seconds or so and listen to the

difference in the fast idle speed. Repeat this procedure with the

H-jet turned a further 1/4 turn anti-clockwise.

•

You have now run the machine at settings of H =±0, H=+1/4,

H=+1/2 relative to the basic settings. At full throttle the engine

has sounded different for each setting. The H-jet is correctly

adjusted when the machine burbles a little. If the machine

”screams” then the machine is set too lean. If the muffler emits

a lot of smoke and the machine burbles a lot then the setting is

too rich. Turn the H-jet clockwise until the setting sounds right

CAUTION! To ensure correct adjustment you should enlist a

qualified mechanic who has access to a tachometer. The

recommended maximum fast idle speed must not be exceeded.

Correctly adjusted carburettor

When the carburettor is correctly adjusted the machine

accelerates without hesitation and 4-cycles a little at full throttle.

It is also important that the chain does not rotate at idle. If the L-

jet is set too lean it may cause starting difficulties and poor

acceleration. If the H-jet is set too lean the machine will have less

power, poor acceleration and could suffer damage to the engine.

If both the L and H jets are set too rich it will results in

acceleration problems or too low a working speed.

Checking, maintaining and servicing

chain saw safety equipment

Chain brake and front hand guard

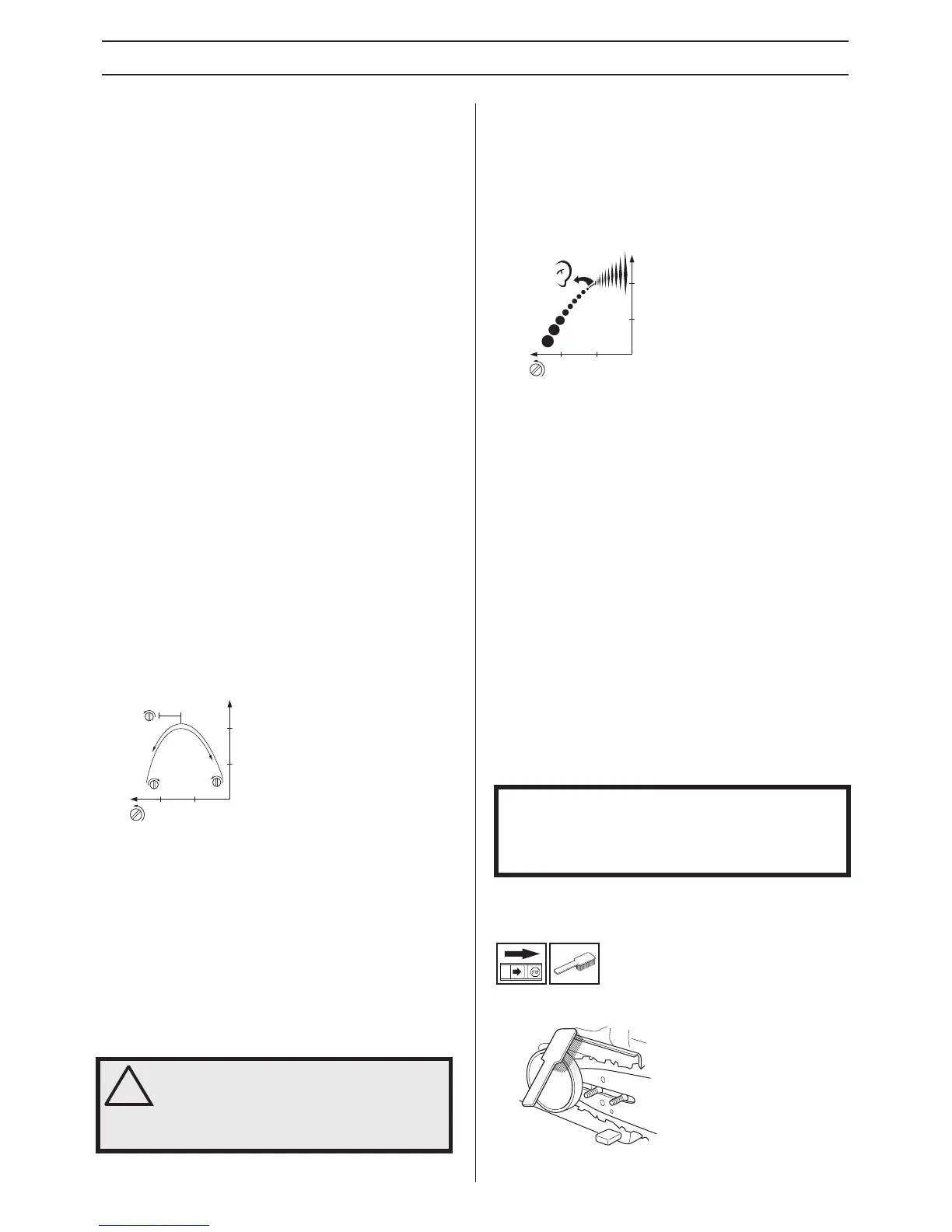

Checking brake band wear

Brush off any wood dust, resin and dirt from the chain brake and

clutch drum. Dirt and wear can impair operation of the brake.

Regularly check that the brake band is at least 0.6 mm thick at

its thinnest point.

Max. fast idle speed, rpm Idle speed, rpm

385XP 12500 2700

390XP 13500 2700

!

WARNING! Contact your servicing dealer, if

the idle speed setting cannot be adjusted so

that the chain stops. Do not use the chain

saw until it has been properly adjusted or

repaired.

L

+ 1/4

Note! All service and repair work on the machine demands

special training. This is especially true of the machine’s

safety equipment. If your machine fails any of the checks

described below we recommend that you take it to your

service workshop.

H

Loading...

Loading...