REV D 4-10 604466

NOTES:

1. Initial oil change is after 5 hours of operation. Thereafter, change oil after every 40 hours operation. Change more often under dusty or dirty conditions and dur-

ing hot weather periods.

2. T

orque initially and after first 2 hours of operation.

3. Perform

initial hydraulic oil and filter change after 750 hours of operation.

4. Change engine

oil filter per the engine manufacturer’s recommendations. Refer to Engine Owner’s Manual for recommendations and other maintenance items.

5. Service more often under dusty or dirty conditions. U

se caution when servicing to prevent dust contamination in the engine. Do not clean filter element. Replace

with a new one.

6. Pump

drive belt only - Inspect every 100 hours and replace if worn or cracking is noticed. Otherwise, replace every 400 hours or 2 years whichever comes

first.

7. Chec

k fuel system for any crack or leaks including, but not limit to, fuel line hoses, fuel valve, vent line hoses, vent valve, vapor valve, carbon canister, and

grommets. Repair as needed.

8. M

ore often under dusty or dirty conditions and during hot weather.

9. Inspec

t ROPS after the first 20 hours of operation and then after every 500 hours of operation or yearly whichever comes first.

REFERENCES:

A. Refer to engine owner’s manual for engine service information.

NOTE: A

fter completing maintenance cycle (500 hours), repeat cycle.

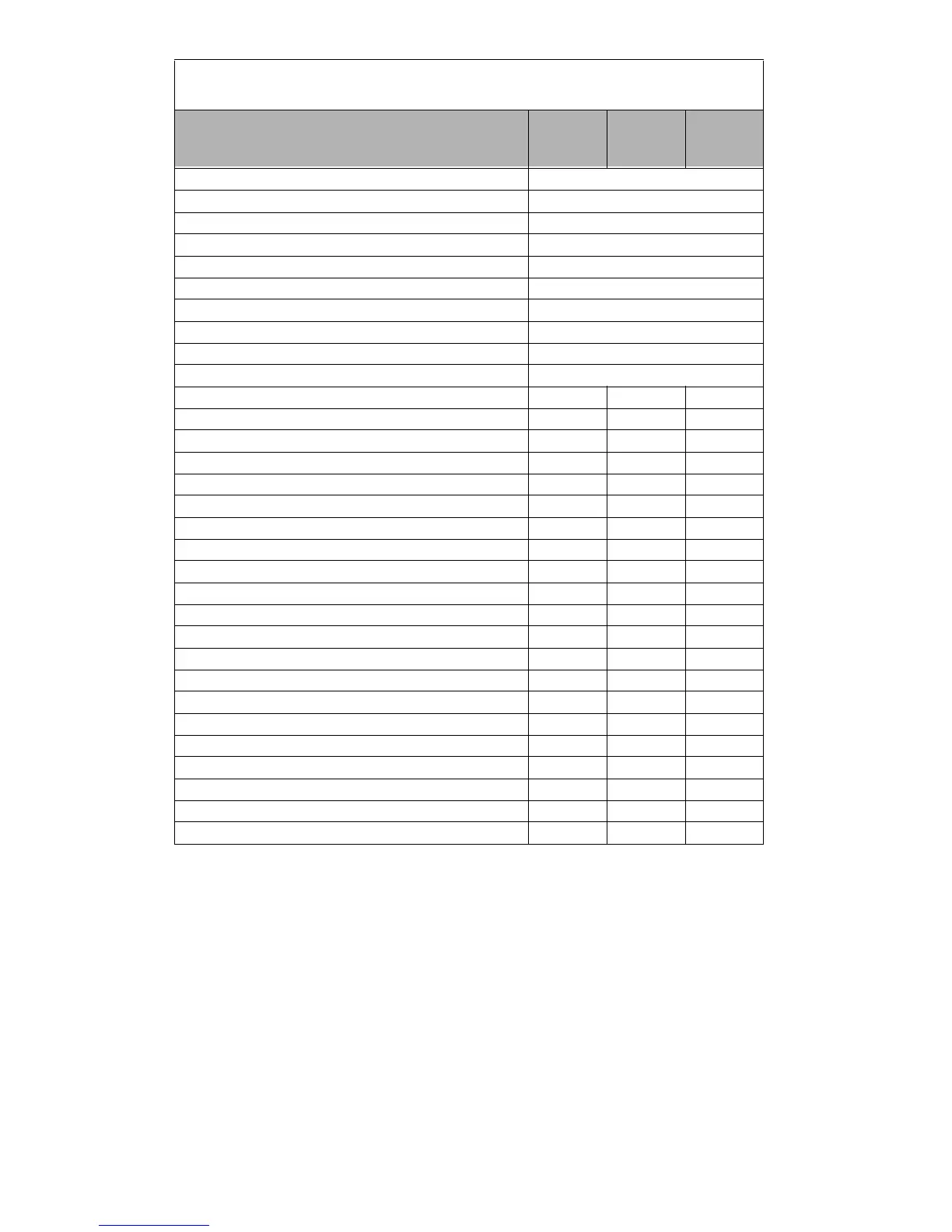

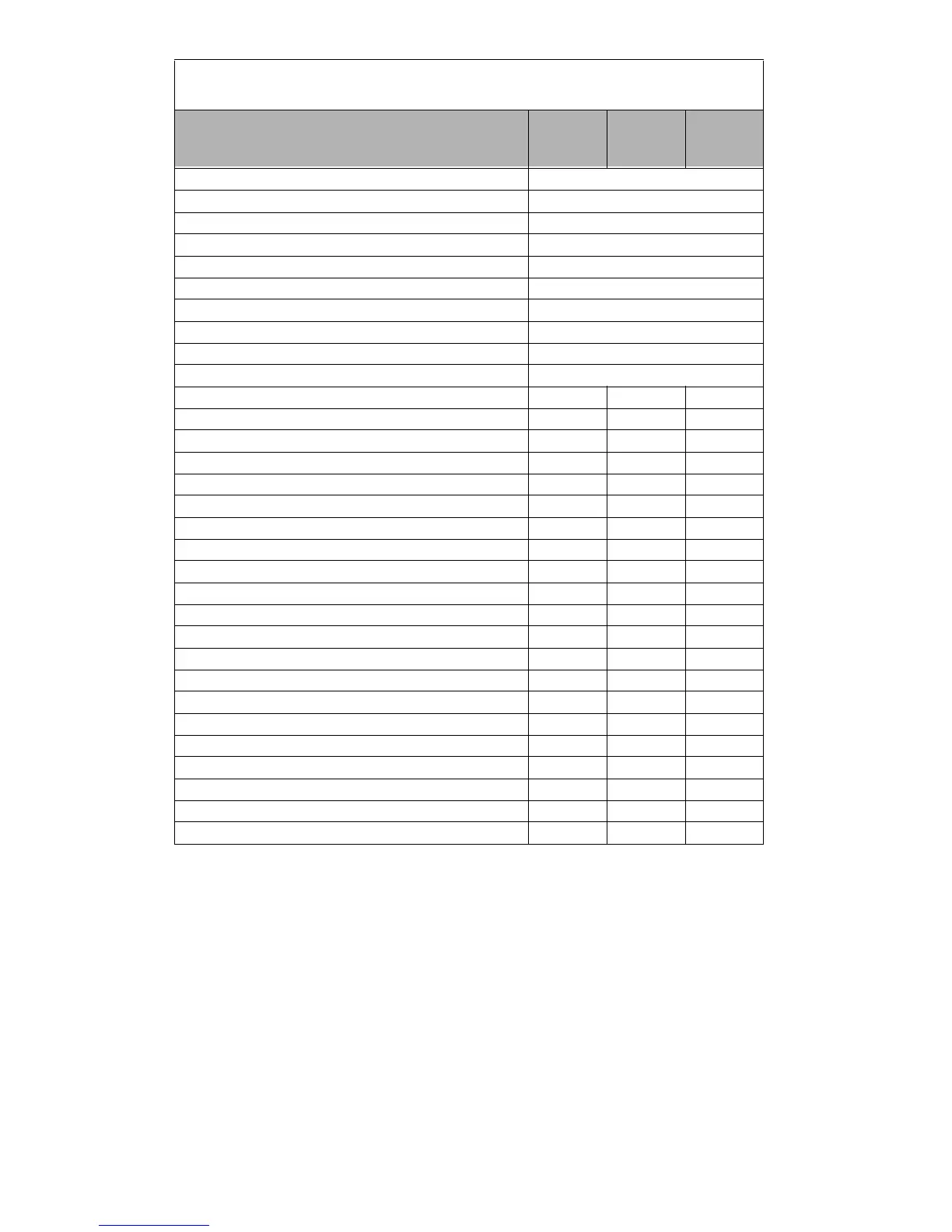

Maintenance Schedule

Figure 4-15, Figure 4-16, Figure 4-17, Figure 4-18 & Figure 4-19

SERVICE AT

INTERVALS INDICATED

WEEKLY

OR 50

HOURS

MONTHLY

OR 100

HOURS

ANNUALLY

OR 500

HOURS

Verify safety start interlock system Prior to each use

Visually inspect unit for loose hardw

are and/or damaged parts Prior to each use

Visually inspect tires Prior to each use

Check oil level, engine (1) Prior to each use or every 4 hours

Clean air intake screen (8) Prior to each use or every 4 hours

Check fuel level Prior to each use

Blades - sharpen & securely fastened Prior to each use

Discharge chute - securely in place & in lowest position Prior to each use

Clean engine and transaxle compartment Daily

Replace air cleaner paper element (5) As needed

Change engine oil and filter (1) (4) X

Clean cylinder and head fins (a) X

Check battery connections X

Check tire pressure with a gauge X

Check hydraulic oil level X

Clean engine exterior (a) X

Grease deck pusher arms (8) X

Grease pump idler (8) X

Grease deck height pivots (8) X

Grease gauge wheel bearings (8) X

Clean & regap spark plugs (a) X

Check pump and deck belt tension and condition (6) X

Check fuel system (7) X

Check hydraulic lines X

Check fuel valve and grommet (7) X

Tighten lug nuts on wheels (2) X

Change fuel filter (7) X

Change hydraulic filter & oil (3) X

Replace spark plugs X

Check ROPS mounting hardware (9) X

Replace fuel evaporation system filter (8) X

Loading...

Loading...