Preventive Maintenance Program

XPR Instruction Manual 809480 25

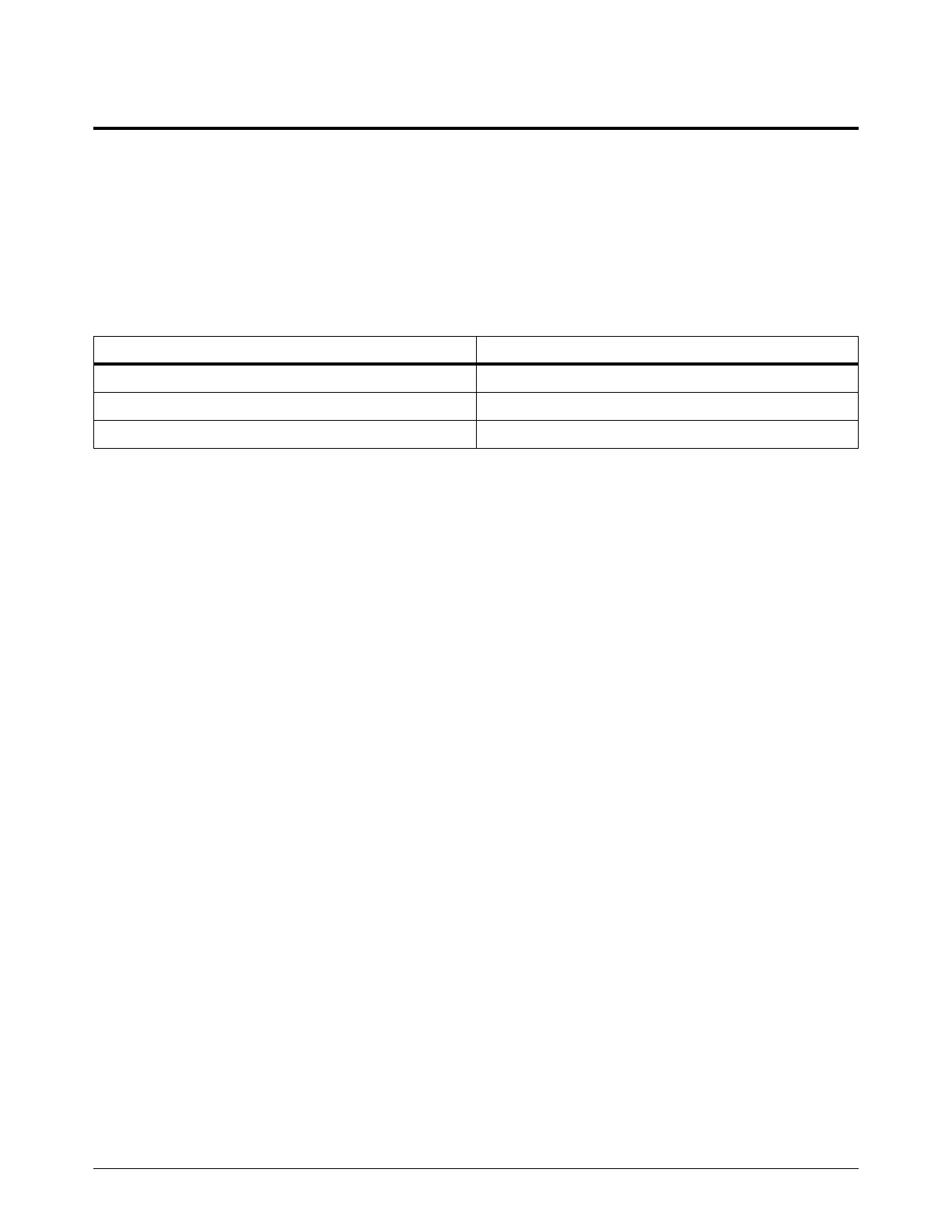

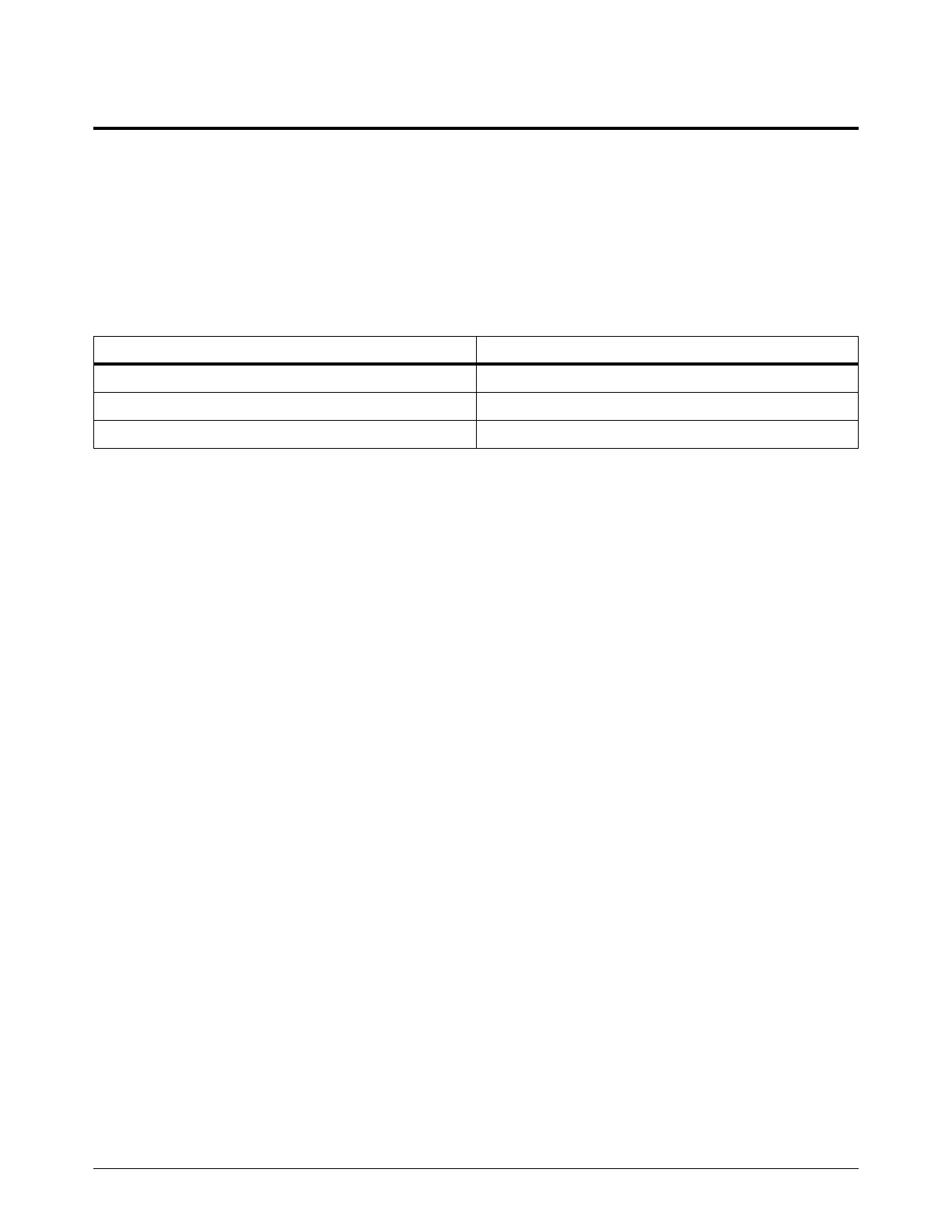

Component replacement schedule

This is a list of components and their recommended replacement schedules. The schedule uses

total arc hours to estimate when to replace a component. The use of cumulative arc hours is the

most accurate method to estimate when you need to replace a component.

If you do not have a Hypertherm CNC and your CNC cannot track arc hours, use the guide below to

estimate arc hours per year. This guide uses the average number of 8-hour shifts that the system

operates on an average work day. For more information about calculating arc hours, contact your

table manufacturer.

Your cutting area and operations can have an effect on this schedule. See Cutting area and

operation effects on page 28.

Record information about your system and its replacement requirements in the following places:

Part numbers for hoses, cables, and leads on page 32

System information on page 39

Notes on page 40

Average shifts per day Estimated arc hours per year

1500

2 1,000

31,500

Loading...

Loading...