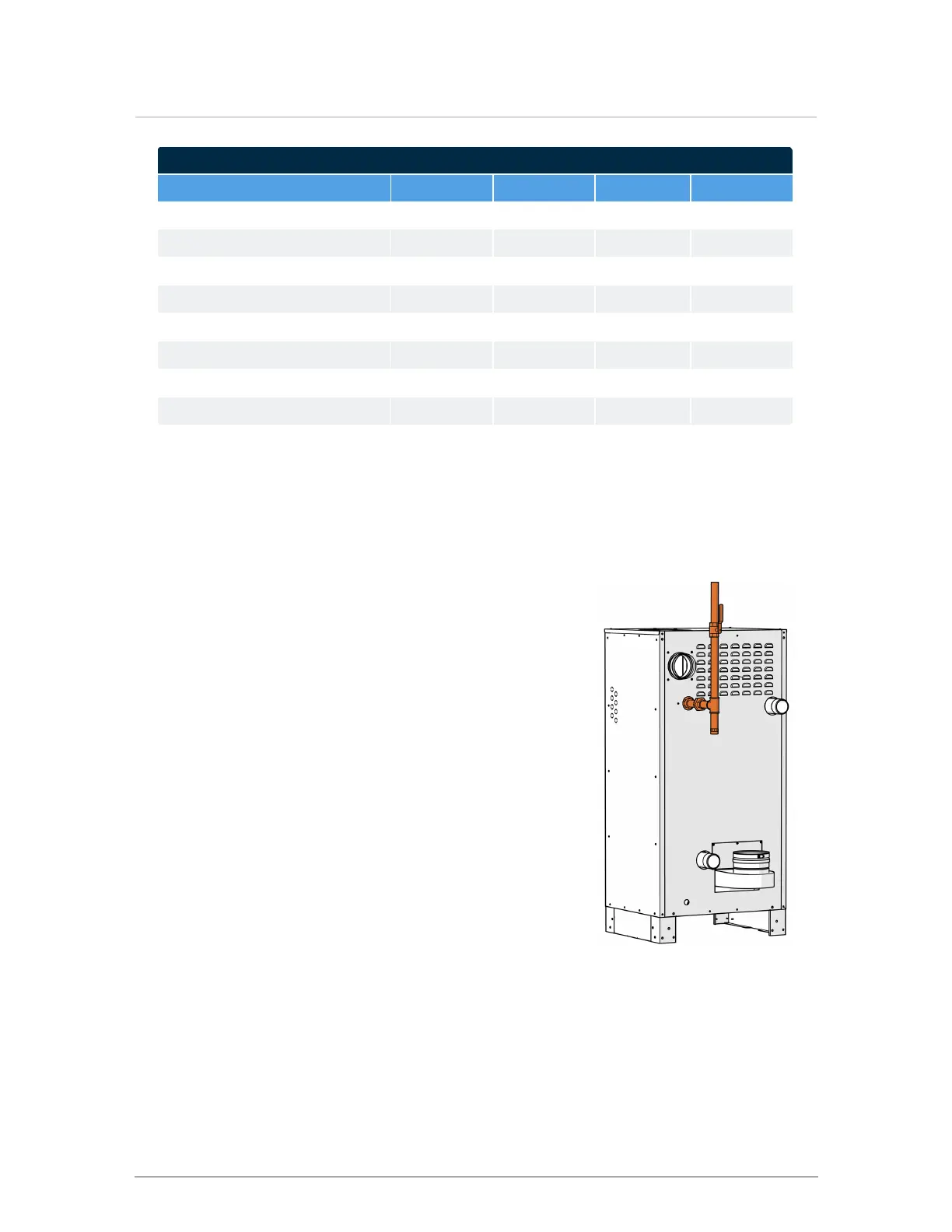

Maximum Gas Pipe Length (ft)

Model 1¼" IPS 1½" IPS 2" IPS 2½" IPS

EX 400 (Natural Gas) 150' 350' 1000' >2000'

EX 400 (Propane) 400' 900' >2000' >2000'

EX 500 (Natural Gas) 100' 200' 700' 1800'

EX 500 (Propane) 250' 600' 2000' >2000'

EX 700 (Natural Gas) 50' 100' 350' 800'

EX 700 (Propane) 150' 300' 900' 2000'

EX 850 (Natural Gas) 40' 80' 250' 600'

EX 850 (Propane) 100' 200' 700' 1600'

Table 9 Maximum Gas Pipe Length (ft)

Gas piping must have a sediment trap ahead of the boiler’s gas valve. A manual shutoff valve

must be located outside the boiler, in accordance with local codes or standards. All threaded

joints in gas piping should be made with an approved piping compound resistant to the action of

natural gas or propane. Use proper hangers to support gas supply piping as per applicable codes.

The boiler must be disconnected or otherwise isolated from the

gas supply during any pressure testing of the system at test

pressures in excess of ½ psig. Dissipate test pressure prior to

reconnecting. The boiler and its gas piping shall be leak tested

before being placed into operation.

The gas valve is provided with pressure taps to measure gas

pressure upstream (supply pressure) and downstream (manifold

pressure) of the gas valve (see Figure 42 or Figure 43 ). Note that

manifold pressure varies slightly in accordance with firing rates

with the modulating series boilers, but will always be close to 0"

wc. An adapter fitting is supplied with the boiler.

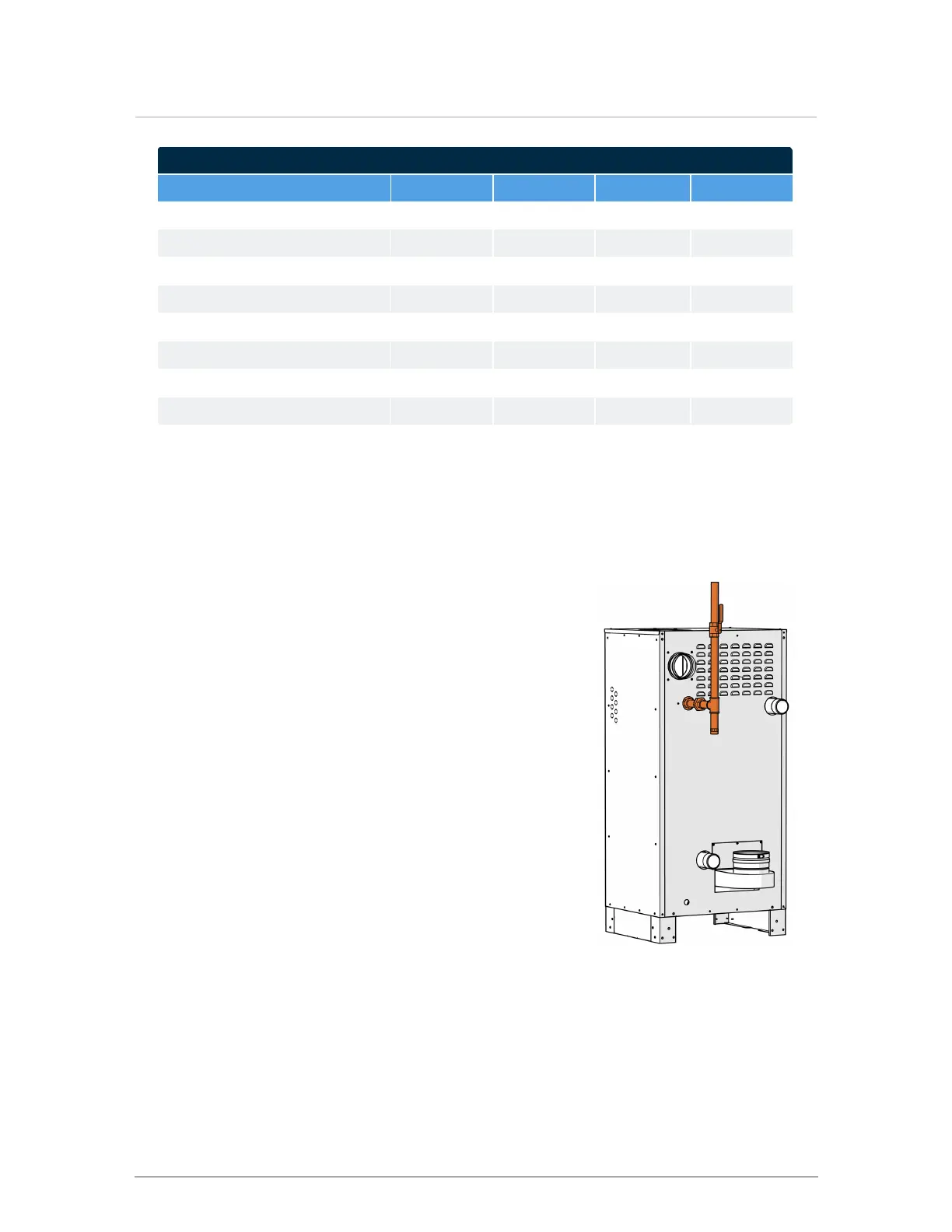

Figure 35 Typical gas piping

3.10 Electrical connections

All electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or

to the National Electrical Code, ANS/NFPA No. 70 – latest edition, or to the Canadian Electrical

Code, C22.1 - Part 1.

Loading...

Loading...