15

USER’S INFORMATION MANUAL

SFT SERIES WATER HEATERS

Relief Valve - Maintenance and Testing

The eld-supplied relief valve manufacturer requires that under normal operating

conditions a “try lever test” must be performed every two months. Under severe

service conditions, or if corrosion and/or deposits are noticed within the valve

body, you must test more often. Also perform a “try lever test” at the end of any

non-service period.

Test at or near maximum operating pressure by holding the test lever fully open

for at least 5 seconds to ush the valve seat free of sediment and debris. Then

release the lever and permit the valve to snap shut.

If the lever does not activate, or there is no evidence of discharge, discontinue

use of equipment immediately, and contact a licensed contractor or qualied

service personnel.

If the relief valve does not completely seal, and uid continues to leak from

the discharge pipe, perform the test again to try and ush any debris that may

be lodged in the valve. If repeated attempts fail to stop the leakage, contact a

licensed contractor or qualied service personnel to replace the valve.

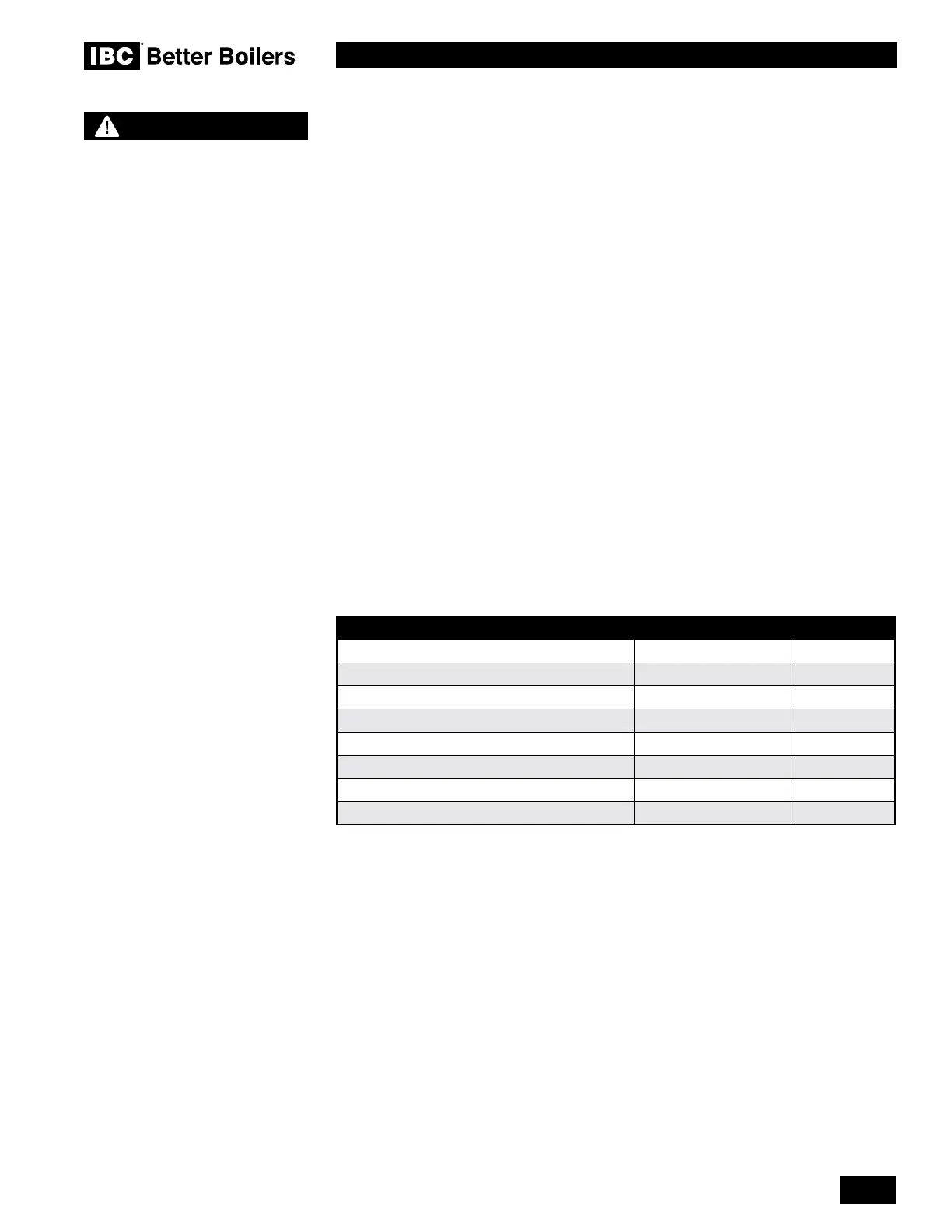

Domestic Hot Water System

Quality of the domestic cold water is very important to the longevity of the unit.

The recommended pH of the domestic water is between 6.5 and 8.5. The internal

domestic water heat exchanger tubing and the ow sensor is subject to fouling if

exposed to hard water (over 7 grains of hardness) or has a TDS of 500mg/L or

higher. See Table 3.

DESCRIPTION MAX MIN

Water Pressure 150 psi 40 psi

Programmable water temperature 149°F (65°C) 104°F (40°C)

Minimum Flow Rate to Activate DHW Sensor N/A 0.5 GPM

Acceptable pH range 8.5 pH 6.5 pH

Chloride 250 mg/L

Iron 0.3mg/L

Total Dissolved Solids 500mg/L

Total Hardness 7 grains

Table 3: Domestic Water Quality Guidelines

CAUTION

Before testing the relief valve,

make certain the discharge

pipe is properly connected to

the valve outlet and arranged

to contain and safely dispose

of equipment discharge.

Loading...

Loading...