5-5

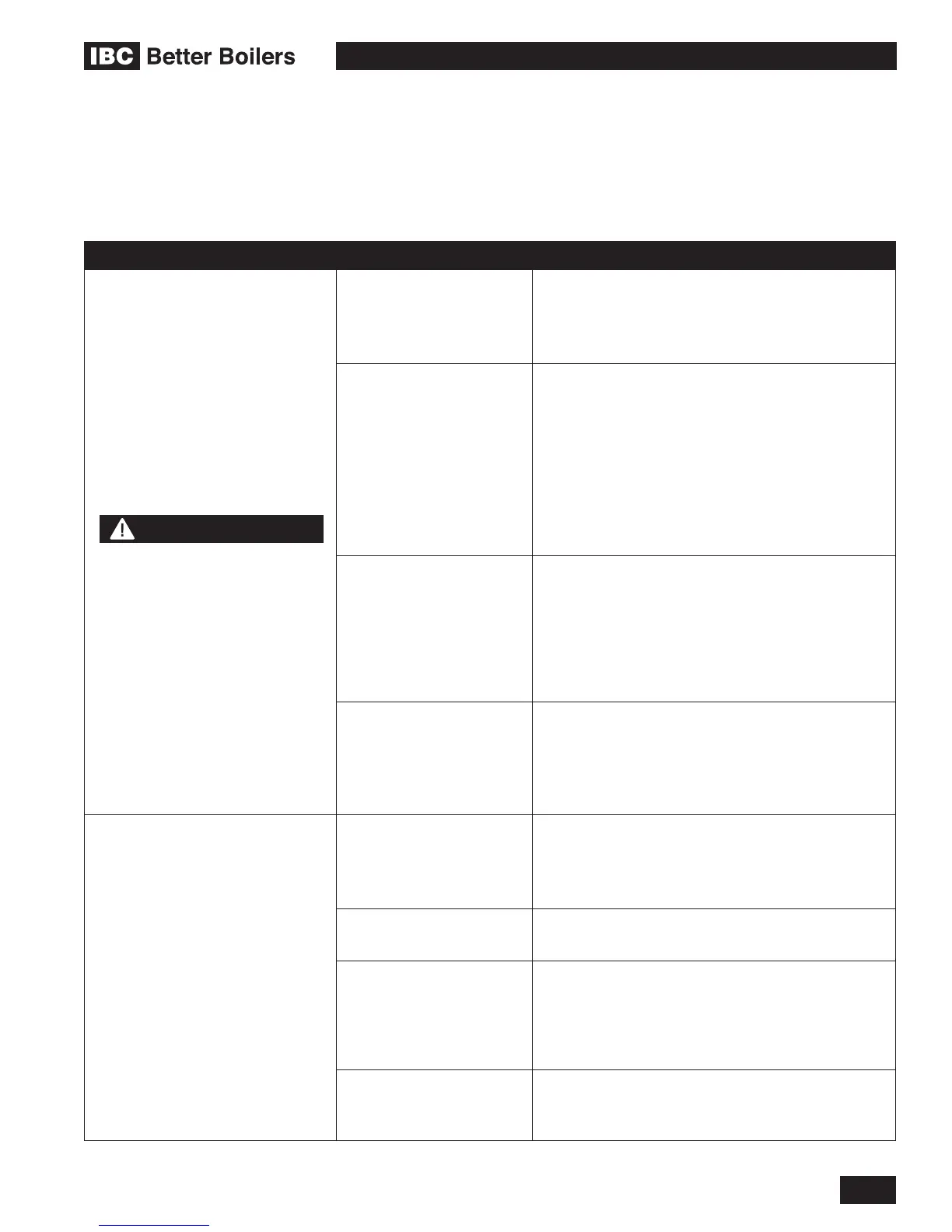

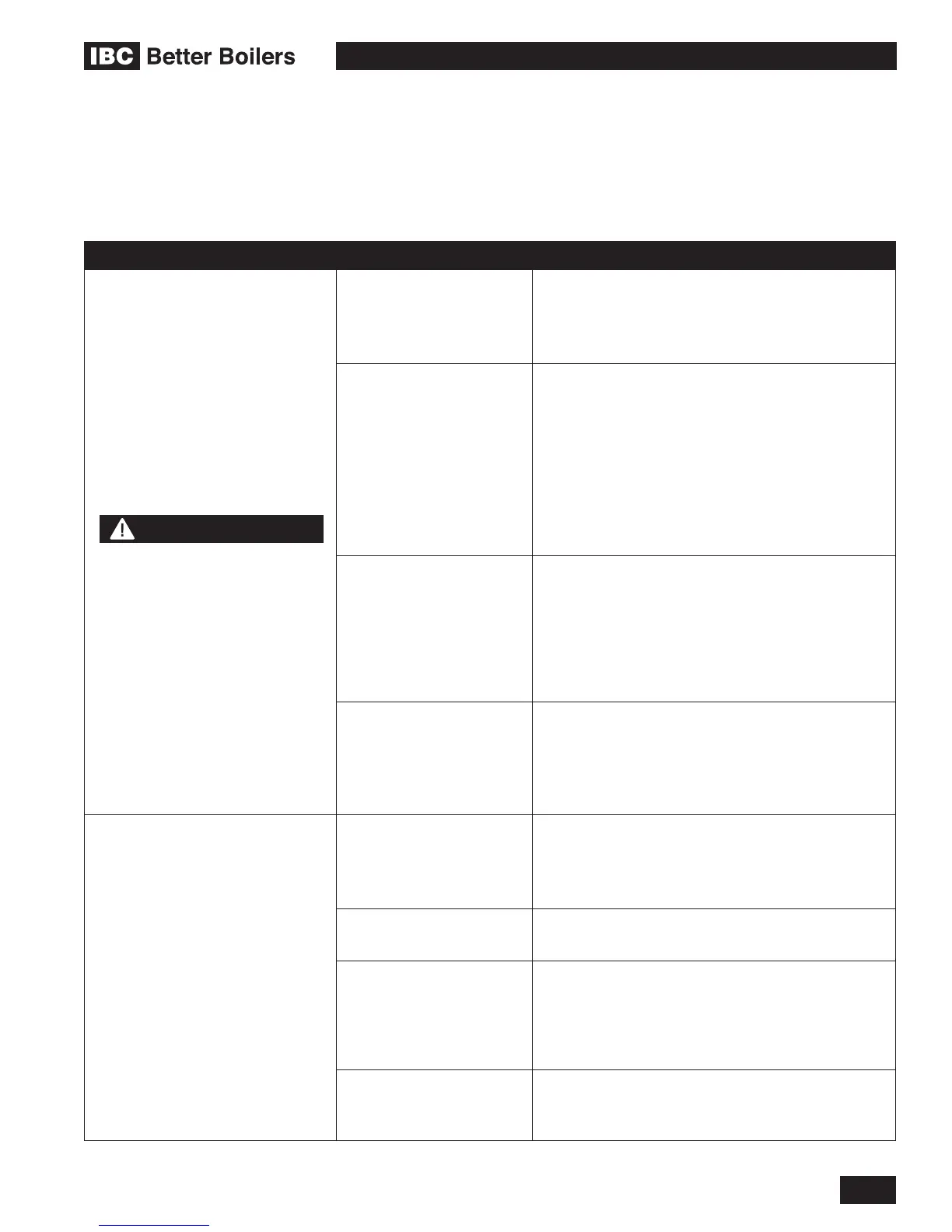

TROUBLESHOOTING

VFC 15-150, VFC 45-225 MODULATING GAS BOILERS

5.3 TROUBLESHOOTING GUIDE

SYMPTOM DIAGNOSIS REMEDY

AIRFLOW ERROR

Touch Screen Message:

Error – Low Air Flow

Low combustion airow; soft

error; will retry in 5 minutes

Check fan operation • Check lead is attached at fan.

• Cycle power off/on; listen for fan initialization.

If no action, focus your attention on the fan

itself.

Check for fouled

reference lines and air

sensor

• Check clear vinyl air reference lines below

gas valve for any sign of water. After

disconnecting from black sensor, blow clear.

Check for exhaust re-ingestion, or repeated

power interruptions .

• Ensure condensate trap is not blocked.

• Go to Advanced Diagnostics and check

differential air pressure sensor (at rest and

with fan on). See Section 5.2.3.

Check achieved fan

power

In Diagnostics, Fan Operation, during Pre-

purge, Fan Pressure (FP) should move close to

Required Pressure (RP); if FP only 480 to 600

vs. RP of 1,000 to 1,200, then check for actual

vent system blockage: (a) disconnect intake

within boiler case; (b) open burner then fan/gas

valve looking for debris.

Water noise in vent.

Excess condensate in

venting.

• Check condensate trap for obstructions.

Remove obstructions and rell condensate

trap with water.

• Check vent length, size and conguration,

particularly re: horizontal 2" piping.

WATERFLOW ERROR

Touch Screen Message:

Error - No Water Flow

Low water ow – soft error; will

retry in 5 minutes

Check pressure

sensors

• Check wiring: water pressure sensors to

controller.

• Check pressure sensors. See Section 5.2.4

– 2nd paragraph.

Check for proper

piping

Refer to Section 1.6 Water Piping for

recommended piping installation.

Check primary pump If there is a valve on the primary loop, close it

and listen for cavitation (evidence ow). If not,

go to Installer Setup; select pump purge “on” to

run pumps without a heat call - check for heat

buildup at pump body (indicates no ow).

Check for restriction

in water pipe

Check temperature differential across heat

exchanger at low –medium ring rate if possible.

Examine air strainer components for scale.

WARNING

Never attempt to repair

the control module (circuit

board). If the control module

is defective, replace it

immediately.

5.3.1 Using Control Module Errors Displayed

Loading...

Loading...