3.13.1 Power management, quality and electrical protection

In areas of unreliable power, appropriate surge protectors and or power conditioning equipment

should be installed in power supply wiring circuits.

Note

The IBC boiler (like any modern appliance that contains electronic equipment) must have

a “clean” power supply, and is susceptible to power surges and spikes, lightning strikes

and other forms of severe electrical “noise”. Power conditioning equipment (surge

protectors, APC or UPS devices) may be required in areas where power quality is

suspect.

In temporary or manual operation, for example in new construction heating, use a construction

thermostat or jumper with an in-line on/off switch for on/off management of the boiler. Do not turn off

the heat by removing power to the boiler. This will interrupt the moisture management routine (fan turns

at ultra low rpm for 90 minutes after burner shutdown) resulting in serious damage to the boiler. Treat the

boiler like a computer, where you do not just pull the plug when done.

3.13.2 120VAC line-voltage hook-up

Line-voltage wiring is done within the field-wiring box (see Wiring diagrams on page 97). Connect the

boiler to the grid power using a separate, fused circuit and on/off switch within sight of the boiler. Use

14-gauge wire in BX cable or conduit properly anchored to the boiler case for mains supply and pump

circuits.

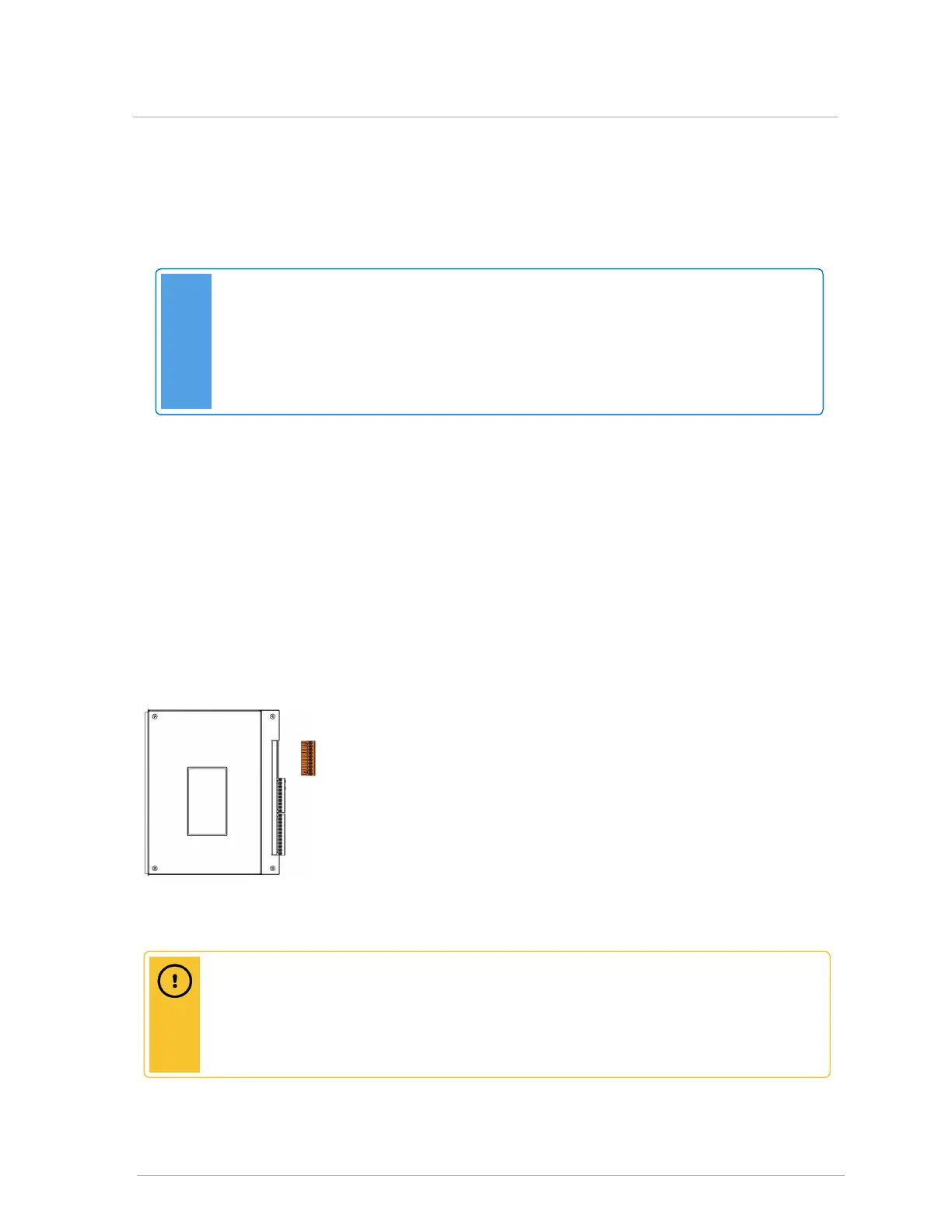

Figure 40 Line voltage load pump terminals

Caution

The on-board controller load pump relays are protected with 5 Amp fuses. The maximum

recommended load on each fuse is 4 Amps (80% of rating). The maximum combined pump

load is 10 Amps. Isolation relays or contactors must be used if the loads exceed these

maximums.

3.13.1 Power management, quality and electrical protection

Loading...

Loading...