CAUTION.

To avoid the possibility of injury during the installation, servicing or cleaning of

this appliance care should be taken when handling edges of sheet steel components.

All Gas Safe Registered Engineers carry a Gas Safe Register ID card, and have a registration number. Both should

be recorded in your Log Book. You can check your installer by calling Gas Safe Register direct on 0800 4085500

Introduction

The boilers are fully automatically controlled, oor

standing, fanned, super efcient condensing appliances.

Due to the very high efciency, condensate is produced from the

ue gases and this is drained to a suitable disposal point through

the plastic waste pipe at the bottom of the boiler. A condensate

'plume' will also often be visible at the ue terminal.

Safety

Current Gas Safety (Installation & Use)

Regulations or rules in force.

In your own interest, and that of safety, it is the law that this boiler

must be installed and maintained by a Gas Safe Registered

Engineer or in IE a competent person, in accordance with the

above regulations.

The appliance should be serviced at least once a year by a Gas

Safe Registered Engineer or in IE a competent person.

It is essential that the instructions in this booklet are strictly

followed, for safe and economical operation of the boiler.

Electricity Supply

The appliance must be earthed.

Supply 230 V - 50 Hz.

This appliance is intended to be connected to the supply via a

double-pole switch, having a 3mm contact separation in both

poles, serving only the boiler and system controls.

Important Notes

• This appliance must not be operated without

the casing correctly tted.

• Do not store objects around or on the boiler, and keep access

clear at all times.

• Do not obstruct ventilation ducts, grilles or openings in the

boiler room, room space or compartment that the appliance is

installed in, or the passage of combustion and ventilation to

the boiler.

• Do not turn off the boiler if it is to be left unattended in frosty

weather.

• If it is known or suspected that a fault exists on the boiler then

it MUST NOT BE USED until the fault has been corrected by a

Gas Safe Registered Engineer or in IE a competent person.

• Flammable materials must not be placed in close proximity to

the appliance. Materials giving off ammable vapours must not

be stored in the same room as the appliance.

In cases of repeated or continuous shutdown a Gas Safe

Registered Engineer or in IE a competent person should be called

to investigate and rectify the condition causing this and carry out

an operational test after each intervention on the device. Only the

manufacturers original parts should be used for replacement.

Minimum Clearances

Rear:

750mm or adequate space from the rear of the jacket to make the

ue connections, drain connection, ue and any safety or control

devices.

Left Side:

400mm.

Right Side:

450mm.

Front:

600mm for normal service and replacement of components.

However, it is noted that 1.2m is required in the event of heat

exchanger replacement.

Top:

300mm (clearance above boiler casing).

2

Natural Gas only

Destination Countries: GB, IE

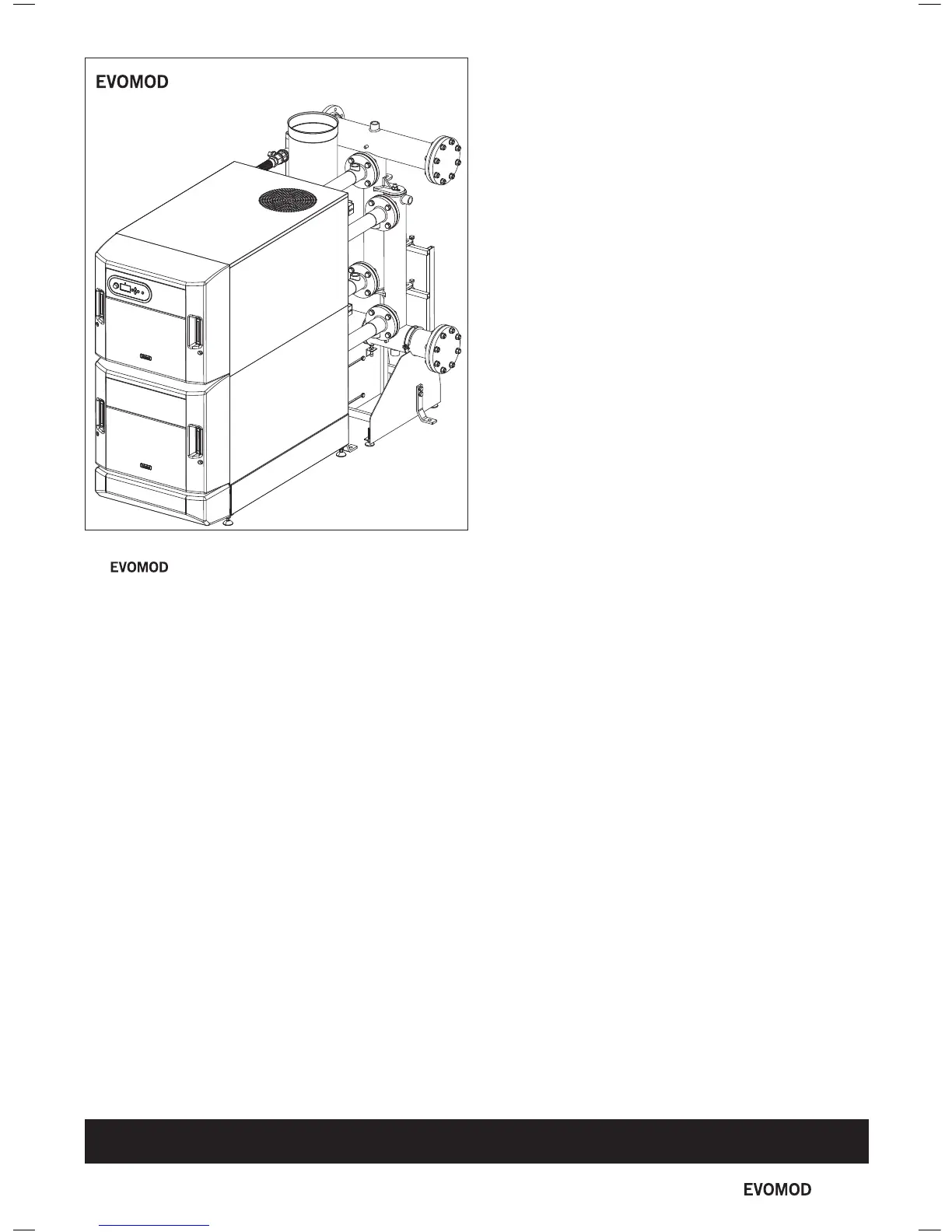

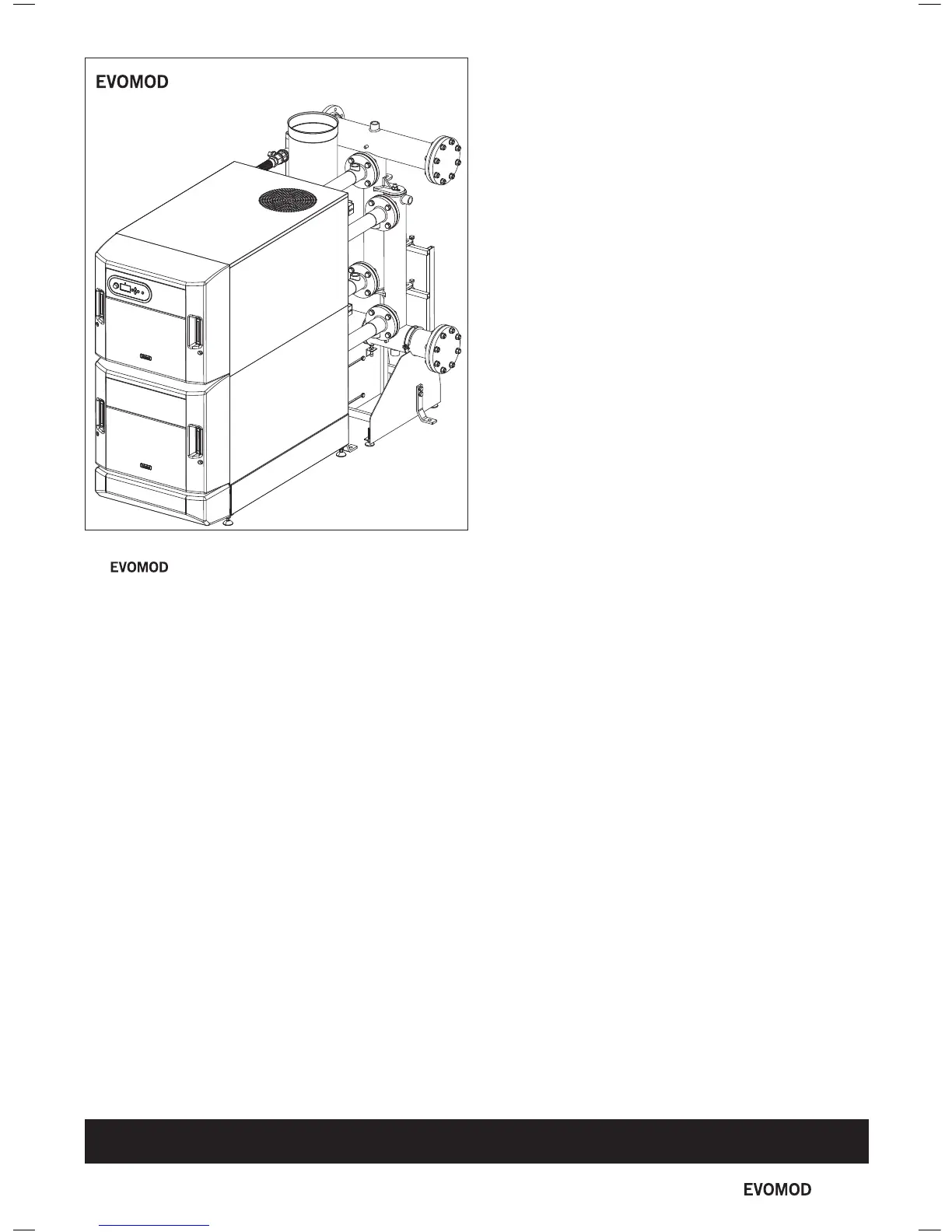

EVOMOD 500 model shown

- Users

Loading...

Loading...