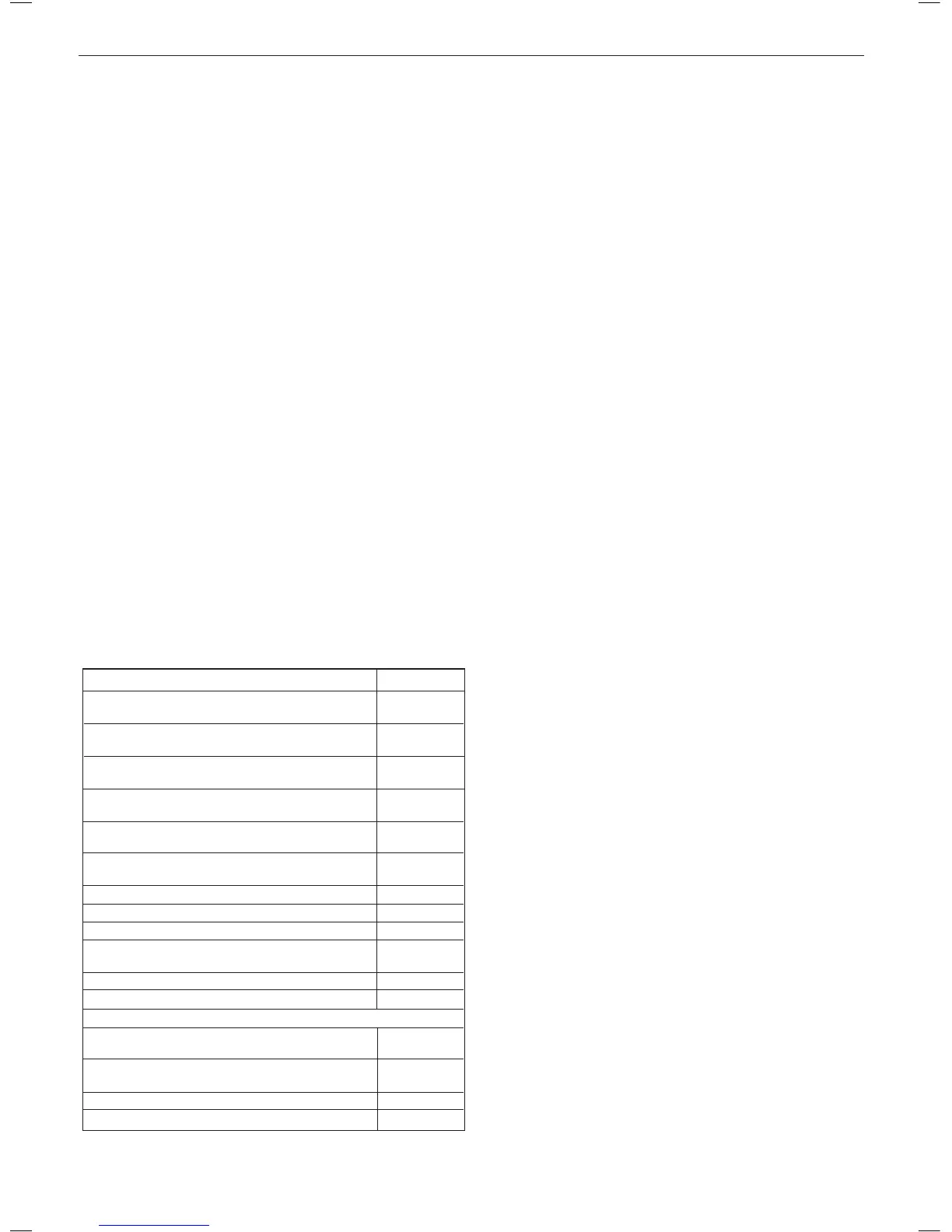

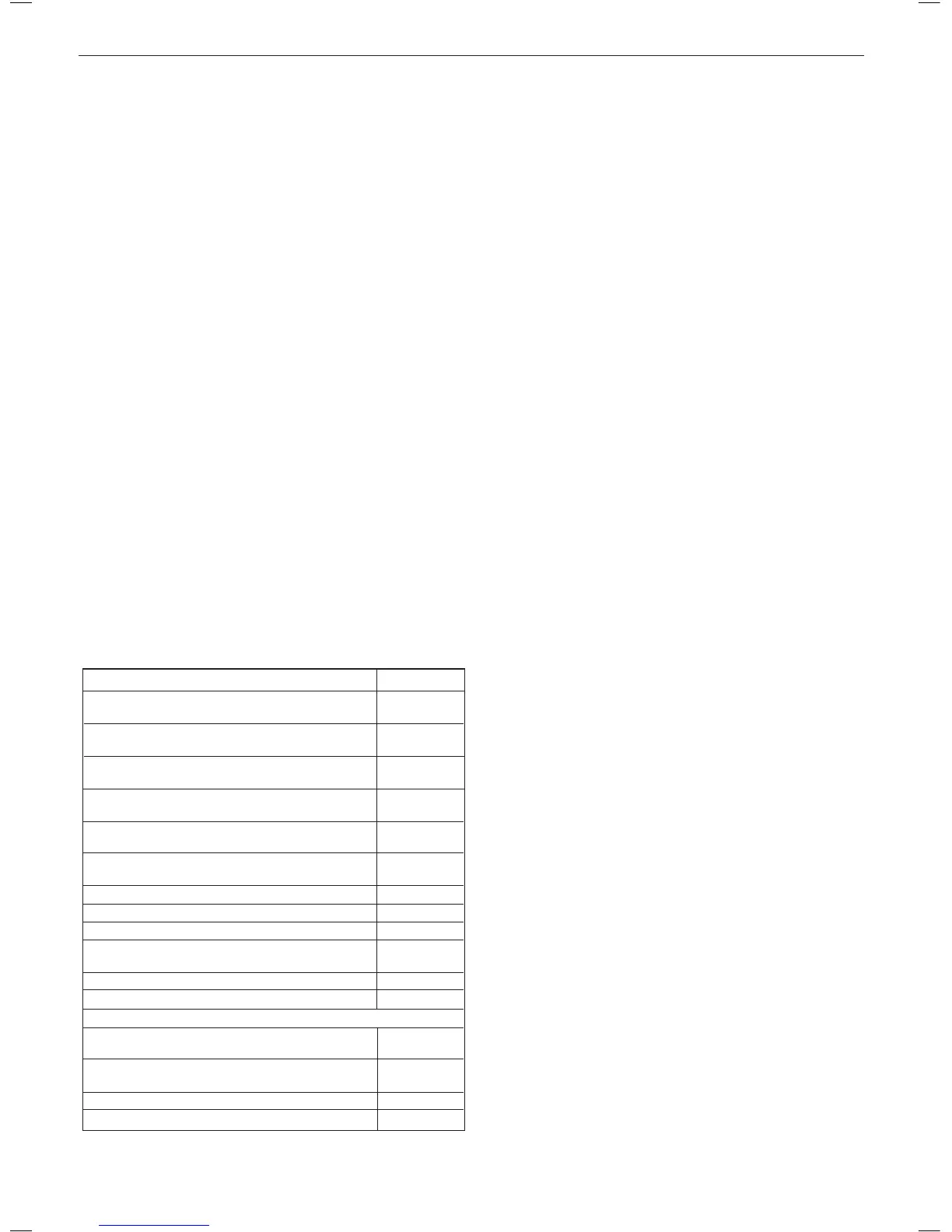

* Only one reduction down to 25mm is allowable per installation

otherwise BS5440-1 2008 dimensions must be followed.

Flue Terminal Positions

Min. Spacing*

1. Directly below, above or alongside an opening

window, air vent or other ventilation opening. 300mm (12”)

2. Below guttering, drain pipes or soil pipes. 25mm ( 1”)*

BS5440-1 2008 75mm (3”)

3. Below eaves. 25mm (1”)*

BS5440-1 2008 200mm (8”)

4. Below balconies or a car port roof. 25mm (1”)*

BS5440-1 2008 200mm (8”)

5. From vertical drain pipes or soil pipes. 25mm (1”)*

BS5440-1 2008 150mm (6”)

6. From an internal or external corner or to a 25mm (1”)*

boundary along side the terminal. BS5440-1 2008 300mm (12”)

7. Above adjacent ground, roof or balcony level. 300mm (12”)

8. From a surface or a boundary facing the terminal. 600mm (24”)

9. From a terminal facing a terminal. 1,200mm (48”)

10. From an opening in a car port

(e.g. door or window) into dwelling. 1,200mm (48”)

11. Vertically from a terminal on the same wall. 1,500mm (60”)

12. Horizontally from a terminal on the wall. 300mm (12”)

13. Above the roof pitch with roof slope of all angles. 300mm (12”)

Above at roof. 300mm (12”)

14. From a single wall face. 300mm (12”)

From corner walls. 300mm (12”)

15. Below velux window 2000mm (79”)

16. Above or side of velux window 600mm (24”)

3. Minimum acceptable spacing from the terminal to

obstructions and ventilation openings are specied in

Table 4.

4. Where the lowest part of the terminal is tted less than 2m

(6’6”) above a balcony, above ground or above a at roof

to which people have access then the terminal MUST be

protected by a purpose designed guard.

Terminal guards are available from boiler suppliers. (Ask for

TFC ue guard model no. K6 - round, plastic coated). In case

of difculty contact:

TFC Group Ltd. Tel. + 44 (0) 01732 351 680

Tower House, Vale Rise Fax. + 44 (0) 01732 354 445

Tonbridge. Kent TN9 1TB www.tfc-group.co.uk

Ensure that the guard is tted centrally.

5. The ue assembly shall be so placed or shielded as to

prevent ignition or damage to any part of any building.

6. The air inlet/products outlet duct and the terminal of the

boiler MUST NOT be closer than 25mm (1”) to combustible

material. Detailed recommendations on the protection of

combustible material are given in BS. 5440-1:2008.

IMPORTANT. It is essential to ensure, in practice, that products

of combustion discharging from the terminal cannot re-enter the

building or buildings through any openings into the building such

as ventilators, windows, doors, or other sources of natural air

inltration, such as forced ventilation openings etc.

If products of combustion re-entry is identied or suspected this

should be immediately investigated and corrected following the

guidance provided in the current Gas Industry Unsafe Situation

Procedure.

TERMINAL

The terminal assembly can be adapted to accommodate various

wall thicknesses. Refer to Frame 10 .

AIR SUPPLY

It is NOT necessary to have a purpose-provided air vent in the

room or internal space in which the boiler is installed. Neither is

it necessary to ventilate a cupboard or compartment in which the

boiler is installed, due to the low surface temperatures of the boiler

casing during operation; therefore the requirements of BS 6798,

Clause 12, and BS 5440:2 may be disregarded.

WATER CIRCULATION SYSTEM

IMPORTANT.

A minimum length of 1 metre of copper pipe MUST be tted to both

ow and return connections from the boiler before connection to

any plastic piping.

The central heating system should be in accordance with BS.6798

and, in addition, for smallbore and microbore systems, BS.5449.

WATER TREATMENT - see Frame 5

BOILER CONTROL INTERLOCKS

Central heating systems controls should be installed to ensure

the boiler is switched off when there is no demand for heating, in

compliance with Building Regulations.

Heating systems utilising full thermostatic radiator valve control

of temperature in individual rooms should also be tted with a

room thermostat controlling the temperature in a space served by

radiators not tted with such a valve.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

a heating requirement of at least 10% of the minimum boiler heat

output should be achieved using a room thermostat, whilst other

rooms are individually controlled by thermostatic radiator valves.

However, if the system employs thermostatic radiator valves on all

radiators, or two port valves, then a bypass circuit must be tted

with an automatic bypass valve to ensure a ow of water should all

valves be in the closed position.

ELECTRICAL SUPPLY

WARNING.

This appliance must be earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply. For IE reference should be made to the

current ETCI rules for electrical installations.

The mains supply to the boiler and system wiring centre shall

be through one common fused double pole isolator and for new

heating systems, and where practical replacement installations, the

isolator shall be situated adjacent to the appliance.

CONDENSATE DRAIN

Refer to Frames 22, 23 & 42

A condensate drain is provided on the boiler. This drain must be

connected to a drainage point on site. All pipework and ttings in

the condensate drainage system MUST be made of plastic - no

other materials may be used.

IMPORTANT.

Installation must be in accordance with BS 6798.

The drain outlet on the boiler is sized for standard 21.5mm (3/4”)

overow pipe. It is a universal tting to allow use of different

brands of pipework.

Loading...

Loading...