Loading...

Loading...

Do you have a question about the Iron Baltic ATV Series and is the answer not in the manual?

| Brand | Iron Baltic |

|---|---|

| Model | ATV Series |

| Category | Lawn Mower |

| Language | English |

Ensures all safety guards are securely attached before operating the mower.

Never contact rotating components while the mower is in operation to prevent severe injury.

Ensure the engine is stopped and rotor has stopped before clearing blockages.

Always wear appropriate personal protective equipment (PPE) for hearing and vision.

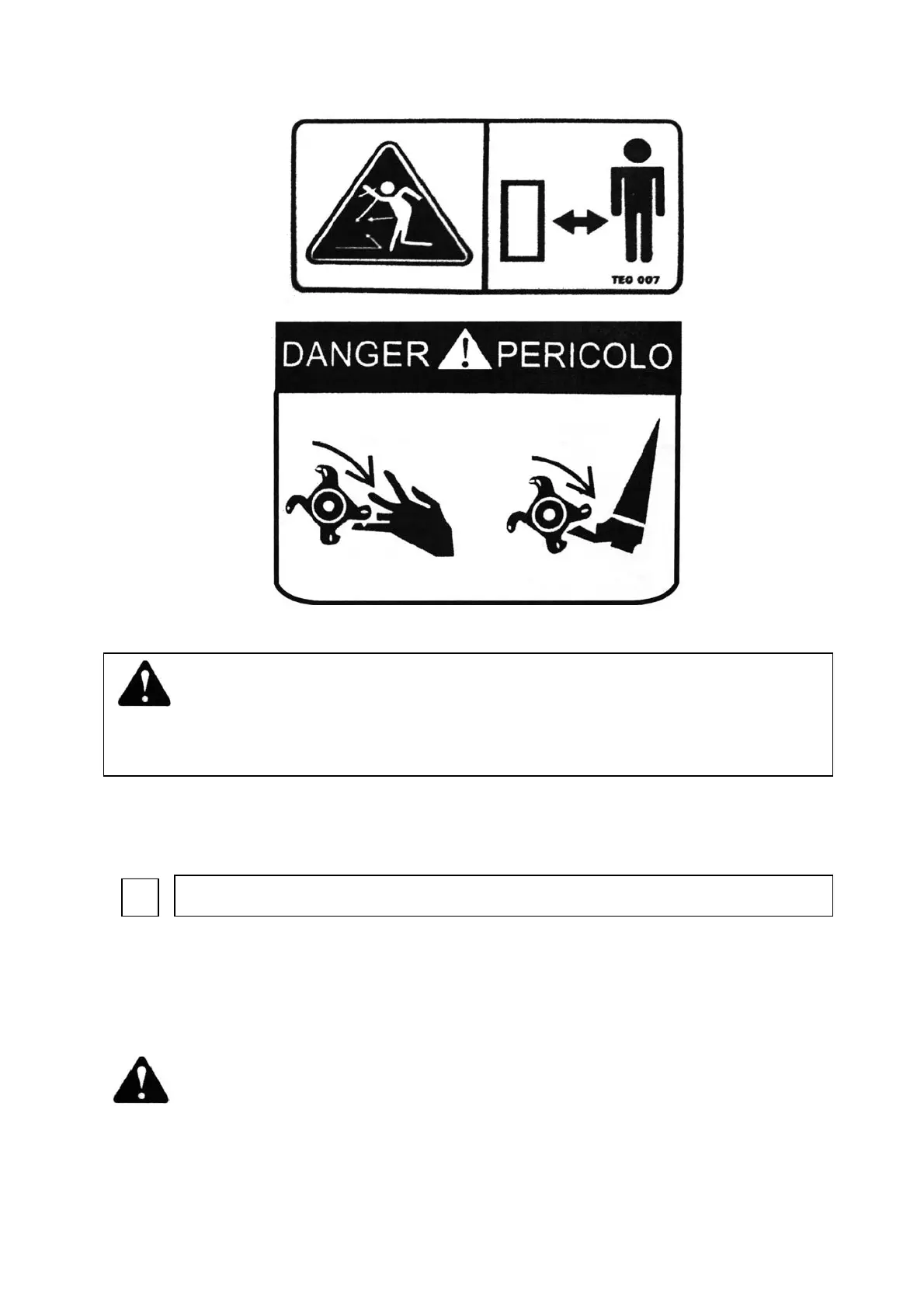

Maintain a safe distance for all bystanders during mower operation.

Perform routine maintenance and pre-operation checks for safety and reliability.

Operate at reduced speeds on uneven ground or slopes for better control.

Maintain a safe distance for hands and feet from the mower's rotating blades.

Crucial warning about operating the machine only after reading and understanding the manual.

Key user responsibilities including reading manuals, training, and ensuring guards are fitted.

Location and importance of danger and hazard warning decals on the mower.

Wear ear defenders when operating with an ATV or tractor due to noise levels.

Verify all nuts, bolts, and fittings are secure and packaging material is removed.

Ensure the engine has sufficient oil and the fuel tank is filled with petrol.

Adjust the drawbar link to ensure the cutting deck is horizontal for efficient cutting.

Use the screw jack handle to adjust the cutting deck to the desired height.

Crucial instruction to read and understand the engine manual before starting.

Follow safety rules, keeping hands and feet clear of moving parts.

Warning against altering RPM beyond limits; it voids warranty and affects performance.

Information on electric start options and connection to ATV power.

Guidance on optimal forward speeds based on cutting conditions and engine load.

Instruction to slow down immediately when encountering heavy cutting conditions.

Warning about severe damage to clutch and belts if engine is overloaded.

Cool down procedure: run at half speed for 4 minutes after heavy use.

Be cautious of hot components like the exhaust and belts after stopping.

Clean debris from cooling fins, belts, and rotors after the mower has cooled down.

Raise the cutting deck to its highest setting for safe transport.

Important notice: The mower is not street legal and must not be used on public roads.

The anti-scalping roller prevents ground damage by taking mower weight on uneven terrain.

Adjust roller and skids lower for rough conditions to increase ground clearance.

Overview of maintenance tasks required hourly, daily, weekly, and seasonally.

Refer to the engine manual for specific engine servicing and maintenance procedures.

Instructions for removing accumulated crop matter to prevent heat build-up and fires.

Inspect the mower for loose, missing, or damaged components and repair as needed.

Warning to not exceed the maximum recommended tyre inflation pressures.

Check rotor bearings for roughness or play by rotating the shaft manually.

Lift the mower to inspect wheel bearings for play and alignment.

Inspect the 50mm coupling and bushes for wear or damage and grease regularly.

Verify all fasteners, guards, and chains are secure and in good condition.

Replace broken or lost flail knives promptly to prevent unbalancing.

Step-by-step guide for replacing or reversing rotor flail knives.

Warning against using damaged or repaired shackles; replace with new parts.

Regularly inspect belts for wear and ensure correct tension to prevent premature wear.

Detailed instructions on how to safely change the mower drive belts.

First step: remove the protective cover from the belts housing.

Loosen the locknut on the tensioner arm to adjust belt tension.

Install new belts onto the pulleys one by one.

Adjust belt tension by turning the pulley arm until 10-15mm compression is achieved.

Belt specifications are available on the housing cover or the manual's first page.

Reattach the belts housing cover after completing belt replacement.

Warning: A worn clutch can lead to premature belt wear; check friction pads regularly.

Step-by-step guide for removing and replacing the clutch assembly.

First, remove the drive belts following the procedure in section 6.10.

Loosen and remove the locknut securing the clutch assembly.

Carefully remove the clutch assembly from the engine crankshaft, using tools if necessary.

Reinstall the drive belts according to the steps outlined in section 6.10.

For complex repairs, consult your authorized dealer for assistance.

Exploded view diagram of the ATV Flail Mower components.

Component: Arm weldment.

Component: Bracket for traction.

Component: Hook for traction.

Component: Axle sleeve.

Component: Shaft tube for traction.

Component: Lifting assembly.

Component: Axle.

Component: Split pin 5X32.

Component: Oil cup M6.

Component: Mut N12.

Component: Plain washer 12.

Component: Protection casing weldment.

Component: Bolt M12x35.

Component: Handle.

Component: Bearing 61904.

Component: Bearing seat.

Component: Bearing 51104.

Component: Screw M8x30.

Component: Adjusting screw.

Component: Sheath for handle.

Component: Cover for tyre.

Component: Bearing 80205.

Component: Tyre.

Component: Rubber cover.

Component: Supporting bracket for tyre.

Component: Nut M10.

Component: Plain washer 10.

Component: Bolt M10x65.

Component: Tension spring.

Component: Bolt M12x70.

Component: Adjusting coil.

Component: Crossbeam weldment.