6. ENGINE ASSEMBLY AND OTHERS

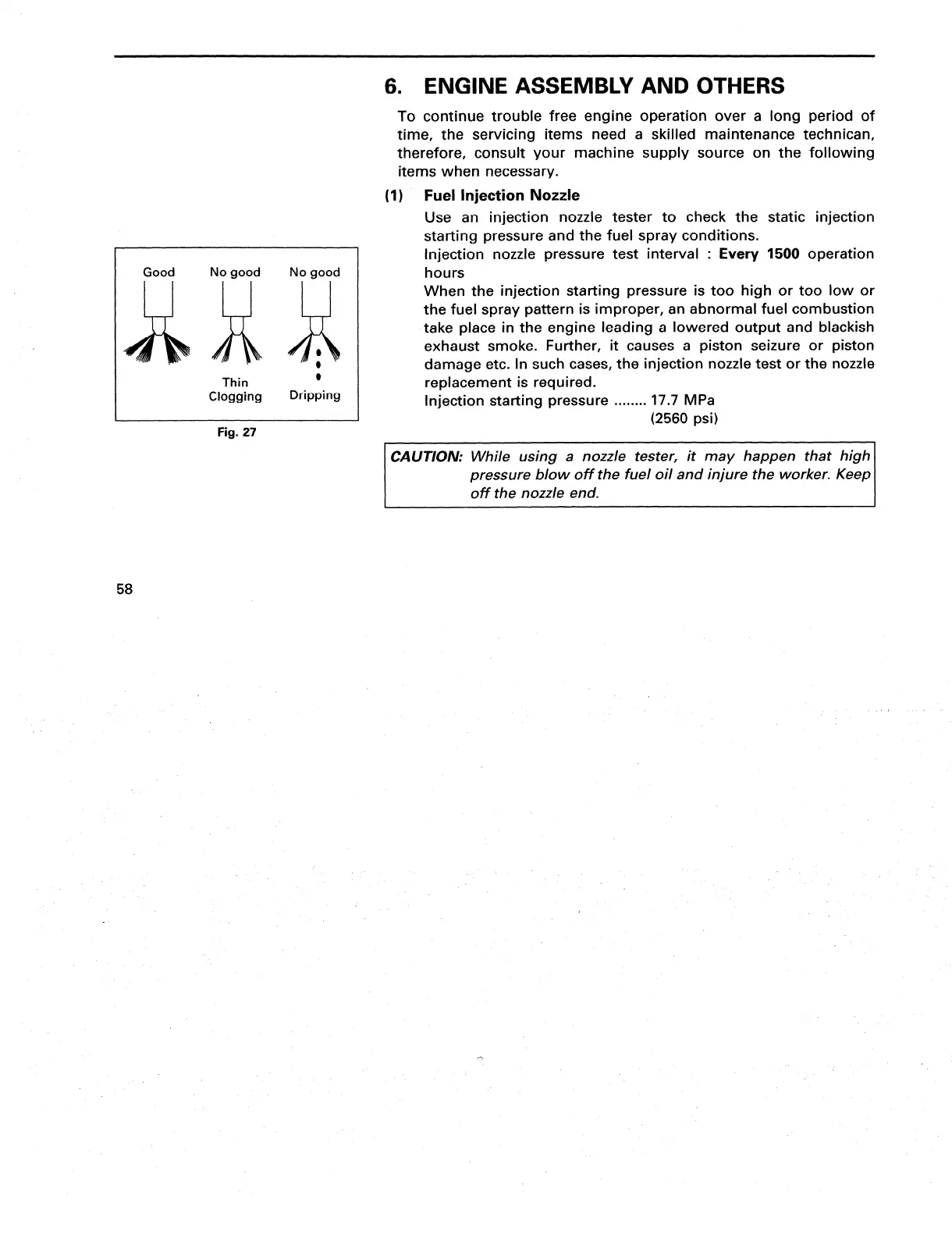

Good

No good No good

x

0

0

Thin

0

Clogging

Dripping

Fig. 27

58

To continue trouble free engine operation over a long period of

time, the servicing items need a skilled maintenance technican,

therefore, consult your machine supply source on the following

items when necessary.

(1) Fuel Injection Nozzle

Use an injection nozzle tester to check the static injection

starting pressure and the fuel spray conditions.

Injection nozzle pressure test interval : Every 1500 operation

hours

When the injection starting pressure is too high or too low or

the fuel spray pattern is improper, an abnormal fuel combustion

take place in the engine leading a lowered output and blackish

exhaust smoke. Further, it causes a piston seizure or piston

damage etc. In such cases, the injection nozzle test or the nozzle

replacement is required.

Injection starting pressure . . . . . . . . 17.7 MPa

(2560 psi)

CAUTION:

While using a nozzle tester, it may happen that high

pressure blow off the fuel oil and injure the worker. Keep

off the nozzle end.

Loading...

Loading...