Maintenance Manual for J2 Sedan

Electronic Control System

163

Section II Structural Principle and

Engine Control System

I. System

Generally, the engine management system is mainly composed of three parts, namely sensors,

micro-processor (ECU), and actuators, to control the intake volume, fuel injection amount, and ignition

advance angle during the running of the engine. The basic structure is shown in the figure below:

Basic Structure of Engine Control System

In the engine electronic control system, the sensors are functioned as input parts to measure all kinds of

physical signals (tempera

etc.) and convert to

ing electric signals, the ECU is

functioned to receive the input signals from sensors, calculate and process as per preset programs,

generate corresponding control signals, and output to power drive circuits, and the power drive circuits

execute different actions by driving corresponding actuators and control the engine to run as per preset

control strategy. At the same time, the malfunction diagnosis system of ECU monitors various

components and control functions in the system. Once a malfunction is detected and confirmed, the

system will save the malfunction code and activate the “Limp home” function. Upon the detection that

the malfunction is resolved, the system will resume to normal values.

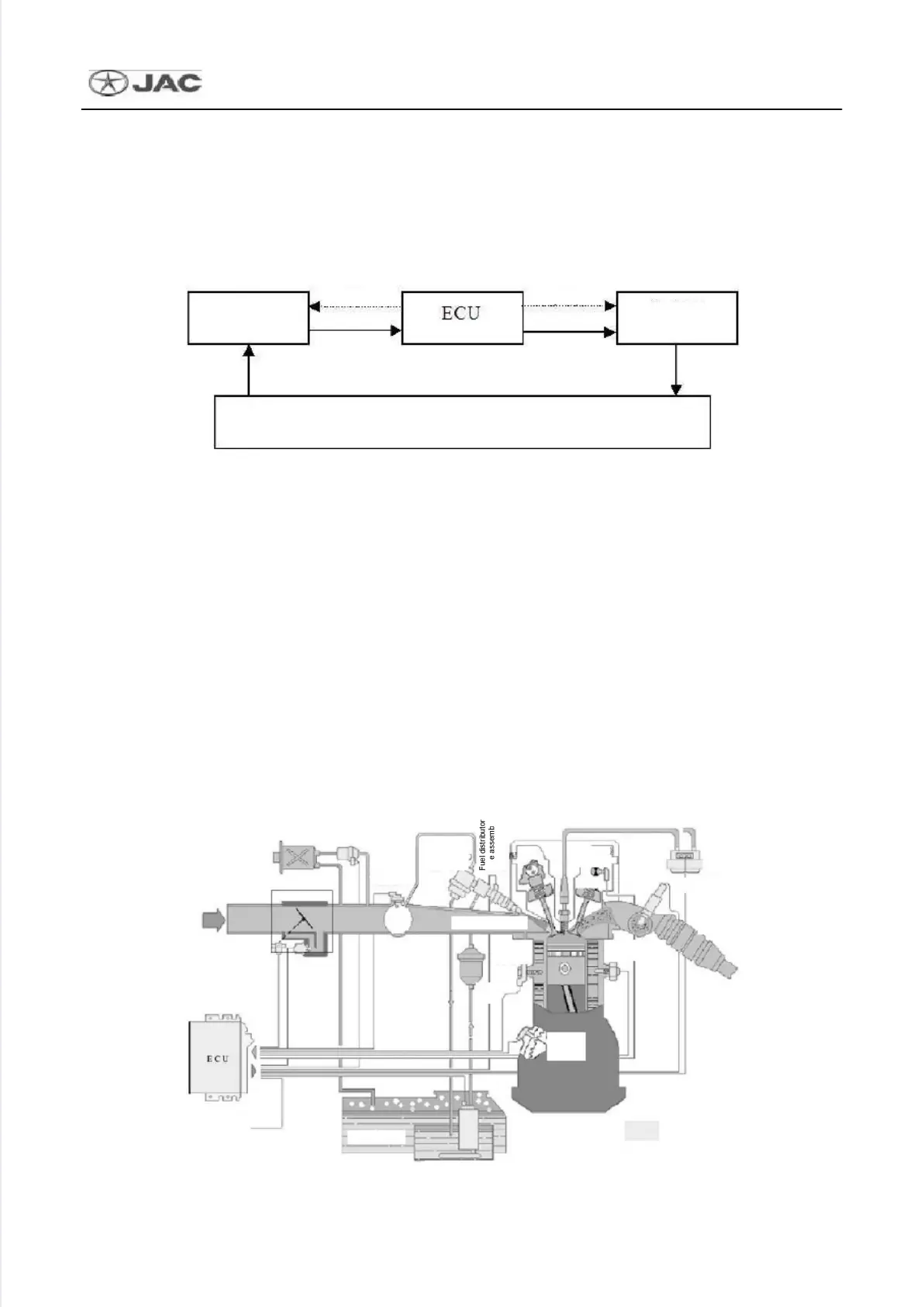

The greatest characteristic in the electronic control system of the M7 engine is the adoption of

torque-based control strategy. The torque-based control strategy is mainly intended to link a great

amount of different control objectives. This is the sole method to integrate flexibly all kinds of functions

into different variants of ECU depending on the engine and vehicle models. The structural diagram of

the electronic control system is shown as below:

Engine

Actuators

Sensors

interface

sensor

sensor

Phase

Intake

sensor

Fuel tank

sensor

control valve

Carbon canister

Loading...

Loading...