15 - Engine

09 - Bedplate

00 - General

15 - 47 9813/9750-1 15 - 47

Figure 135.

D Lower bearing shells (x5)

F Shoulder half-rings (x2)

G Guide pins

6. Apply a 1.0mm (0.04in) thick bead of Loctite 5188

around the crankcase/bedplate mating face as

shown.

Figure 136.

H Crankcase

J Loctite 5188

K Oil feed holes

L Return oil grooves

7. Make sure that you do not block the oil feed holes

and the return oil grooves.

8. Assemble the bedplate to the crankcase. Make

sure that the guide pins on the crankcase are

engaged properly in the slots on the bedplate.

9. Note: The bedplate is heavy. Two people will be

required to lift and rotate the bedplate safely on

to the crankcase.

10. Install the main bearing bolts (x10).

11. Tighten the bolts to the correct torque value in

three stages. Strictly follow the torque sequence

shown.

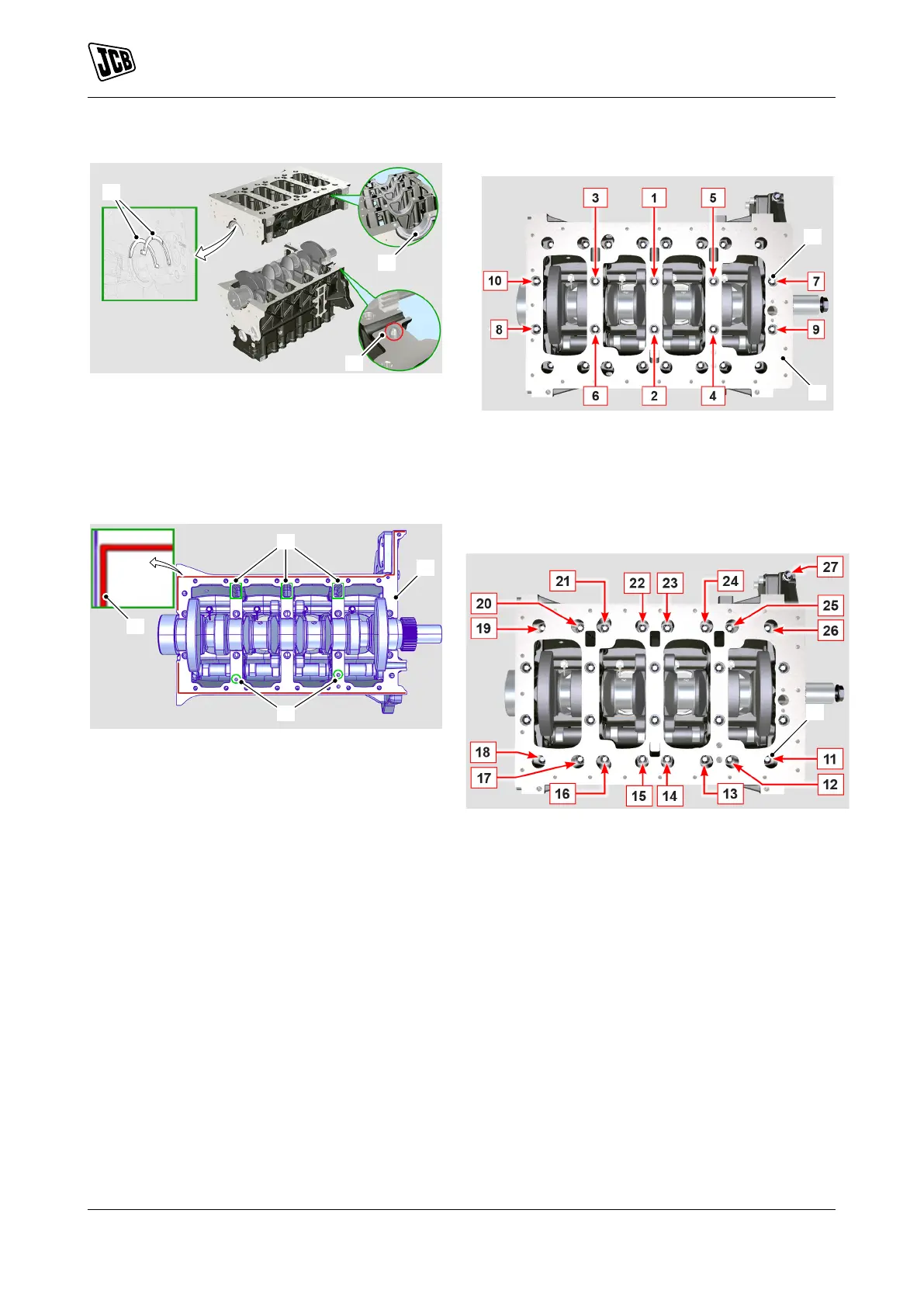

Figure 137.

12. Install the bedplate peripheral bolts (x17).

13. Tighten the bolts to the correct torque value in

two stages. Strictly follow the torque sequence

shown.

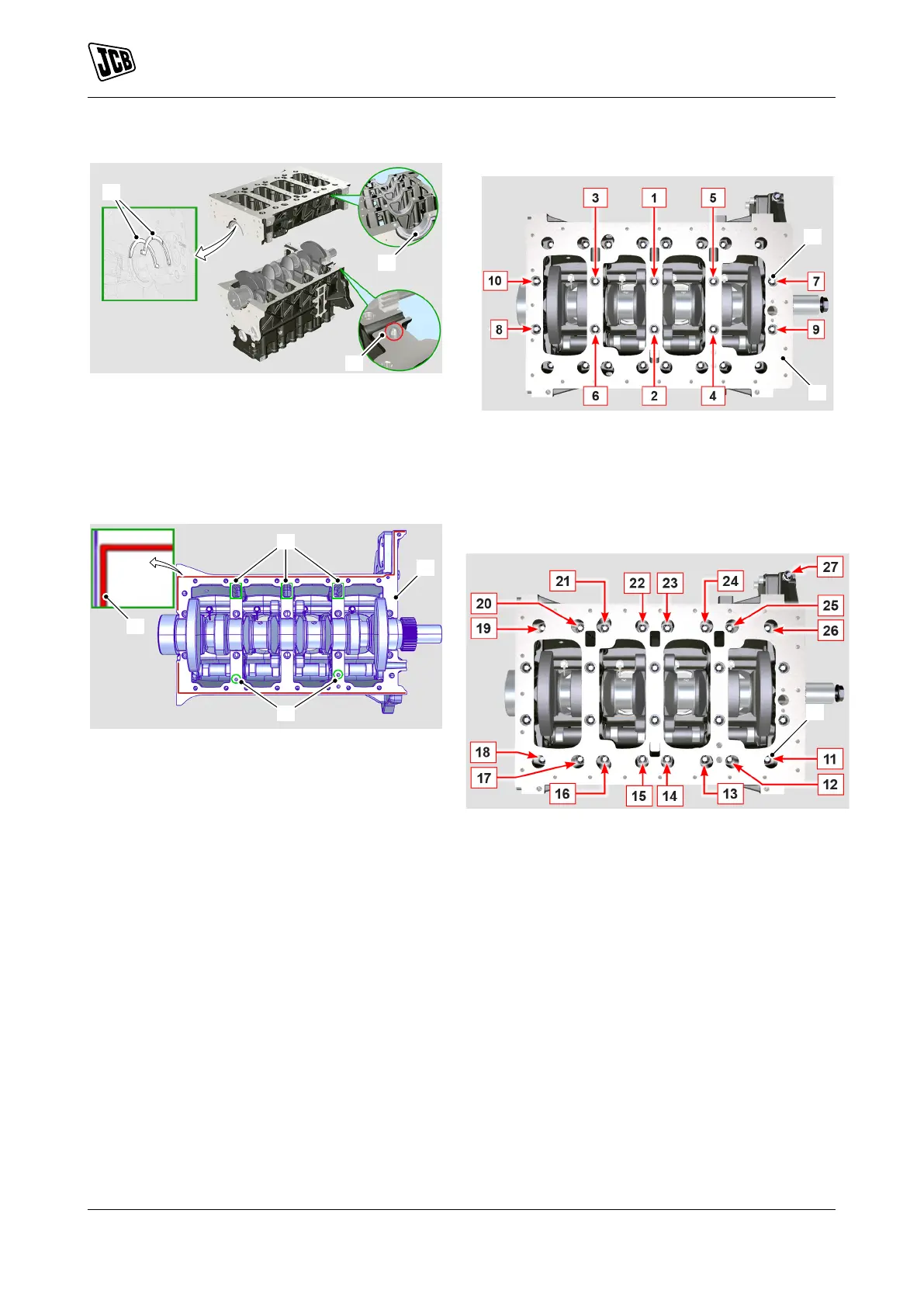

Figure 138.

Important: If the parts have not been tightened to the

correct torque value within the maximum 15min time

period, then the parts must be separated, thoroughly

cleaned and fresh sealant should be applied.

After Installation

1. Check that the crankshaft can be freely rotated

by hand.

2. Measure the crankshaft end float. Make sure that

the end float is between 0.18mm (0.007in) and

0.38mm (0.015in).

3. Carry out the procedures listed in the 'Before

Removal' section in reverse order.

Loading...

Loading...