406, 407 & 409

22

23

Please see operator manual for full details.

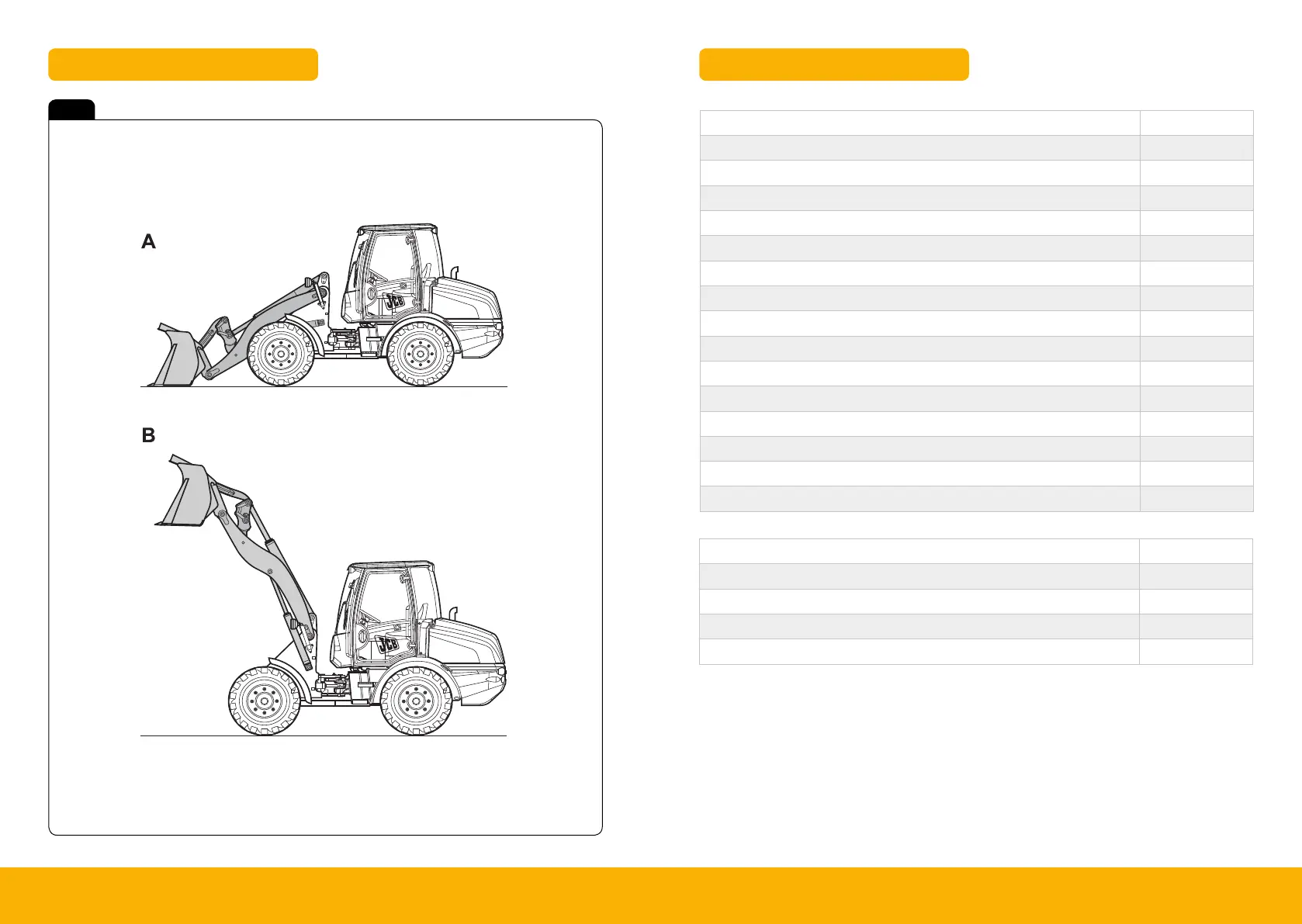

Maintenance Position

Fig 23

Routine Maintenance

Prepare the Machine for Maintenance

132 132

9821-9350-5

Prepare the Machine for Maintenance

Introduction

!MWARNING

Maintenance must be done only by suitably qualified

and competent persons.

Before doing any maintenance make sure the machine

is safe, it should be correctly parked on level ground.

To prevent anyone starting the engine, remove the

starter key. Disconnect the battery when you are not

using electrical power. If you do not take these

precautions you could be killed or injured.

8-3-1-1

Make the machine safe before you start a maintenance

procedure.

You can complete most of the maintenance procedures

with the loader arm lowered (Position A). Unless a

maintenance procedure instructs you differently, you must

lower the loader arm. Refer to How to Make the Machine

Safe (Loader Arm Lowered).

If you lift the loader arm to get access for maintenance

(Position B), you must install the maintenance strut on the

loader arm. Refer to How to Make the Machine Safe

(Loader Arm Lifted).

T021690-3

Fig 87.

Routine Maintenance

Prepare the Machine for Maintenance

132 132

9821-9350-5

Prepare the Machine for Maintenance

Introduction

!MWARNING

Maintenance must be done only by suitably qualified

and competent persons.

Before doing any maintenance make sure the machine

is safe, it should be correctly parked on level ground.

To prevent anyone starting the engine, remove the

starter key. Disconnect the battery when you are not

using electrical power. If you do not take these

precautions you could be killed or injured.

8-3-1-1

Make the machine safe before you start a maintenance

procedure.

You can complete most of the maintenance procedures

with the loader arm lowered (Position A). Unless a

maintenance procedure instructs you differently, you must

lower the loader arm. Refer to How to Make the Machine

Safe (Loader Arm Lowered).

If you lift the loader arm to get access for maintenance

(Position B), you must install the maintenance strut on the

loader arm. Refer to How to Make the Machine Safe

(Loader Arm Lifted).

T021690-3

Fig 87.

Machine Maintenance should be carried out by trained and qualified personnel.

Ensure the machine is parked safe level ground and Isolated.

1. Park machine In Either position A or B depending on task (position B requires safety strut).

2. Isolate and Vent machine, removing Key and Isolator.

Daily Checks (10h) Checks

Condition of attachment / optional equipment Visual

Grease as required all points on machine (ref Operator handbook) Physical

Check machine condition latches bonnets, Visual / physical

Check in Cab switches and functions Visual/physical

Check engine bay Visual

Check engine oil Physical

Check hydraulic oil (sight glass) Visual

Check coolant levels Visual

Check fuel separator (Drain if necessary) Visual / physical

Check coolant pack for dust debris Visual / physical

Check windscreen & washers fluid level Visual / physical

Check operation of all services Physical

Check operation of key items horn lights beacon Visual / audible

Check operation of hour meter, Visual

Check tyres and pressures Visual / physical

Service/Maintenance

Weekly Checks (50h) Check

Grease machine where necessary Physical or Visual

Check tyres and tread Visual

Check machine hose and pipework Visual

Check ram condition Visual

Loading...

Loading...