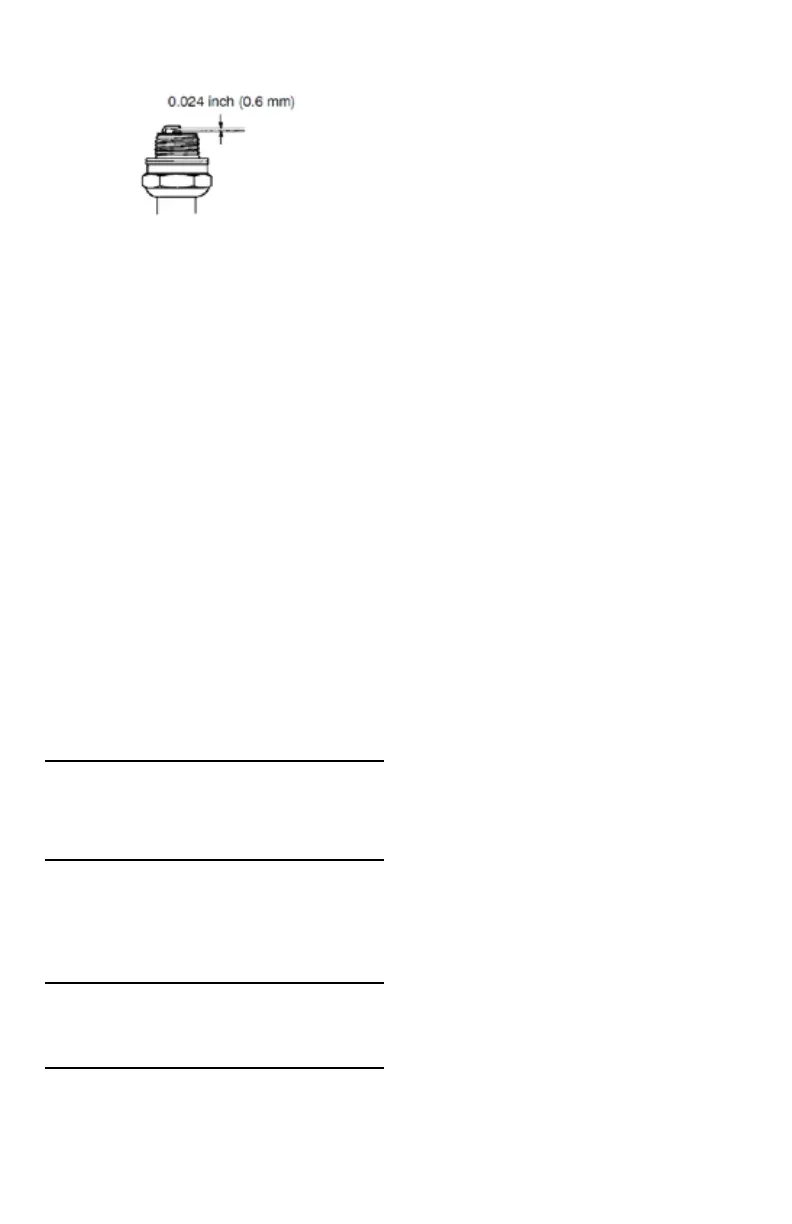

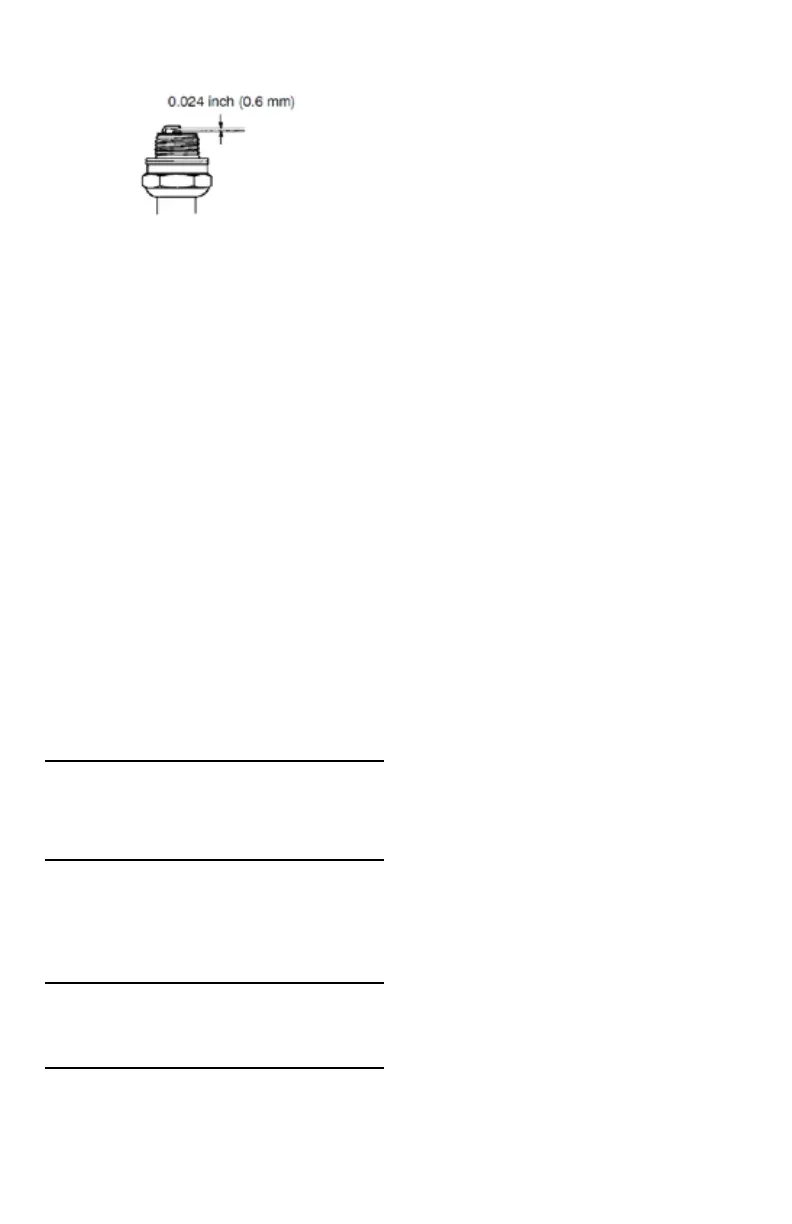

electrode gap is 0.024 inch (0.6 mm). The spark plug

should be replaced after about a month in operation or

earlier if necessary.

CAUTION: Always use the recommended spark

plug type. Use of the wrong spark plug can damage

the piston/cylinder.

Air lter

The air lter must be regularly cleaned to remove dust

and dirt in order to avoid:

● carburetor malfunctions

● starting problems

● loss of engine power

● unnecessary wear to engine parts

● excessive fuel consumption

Clean the lter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Cleaning the air lter

Remove the air lter cover and take out the lter.

Wash it clean in warm, soapy water. Rinse thoroughly.

Ensure that the lter is dry before retting it.

An air lter that has been in use for a long time cannot

be cleaned completely. The lter must therefore

be replaced with a new one at regular intervals. A

damaged air lter must always be replaced.

Bevel gear

The bevel gear is lled with the right quantity of grease

at the factory. However, before using the machine

you should check that the bevel gear is lled three-

quarters full with grease. Use special grease. The

grease in the bevel gear does not normally need to be

changed except if repairs are carried out.

Sharpening grass cutters and grass

blades

aWARNING: Always stop the engine before

doing any work on the cutting attachment. This

continues to rotate even after the throttle has

been released. Ensure that the cutting attachment

has stopped completely and disconnect the lead

from the spark plug before you start to work on it.

● See the cutting attachment packaging for correct

sharpening instructions.

● Sharpen blades and cutters using a single-cut at

le.

● Sharpen all edges equally to maintain the balance

of the blade.

aWARNING: Always discard a blade that is

bent, twisted, cracked, broken or damaged in any

other way. Never attempt to straighten a twisted

blade so that it can be reused. Only use original

blades of the specied type.

Maintenance schedule

The following is a list of the maintenance that must

be performed on the machine. Most of the items are

described in the Maintenance section. The user must

only carry out the maintenance and service work

described in this Operator’s Manual. More extensive

work must be carried out by an authorized service

workshop.

Weekly Maintenance:

● Clean the outside of the machine.

● Make sure the throttle trigger lock and the throttle

function correctly from a safety point of view.

● Check that the stop switch works correctly.

● Check that the cutting attachment does not rotate

at idle.

● Clean the air lter. Replace if necessary.

● Check that the cutting attachment guard is

undamaged and not cracked. Replace the cutting

attachment guard if it has been exposed to impact

or is cracked.

● Check that the trimmer head is undamaged and not

cracked. Replace the trimmer head if necessary.

● Check that the locking nut of the cutting equipment

is tightened correctly.

● Check that nuts and screws are tight.

● Check that there are no fuel leaks from the engine,

tank or fuel lines.

Monthly Maintenance:

● Check the starter and starter cord.

Annual Maintenance:

● Clean the outside of the spark plug. Remove it and

check the electrode gap. Adjust the gap to 0,6 mm

(1/32 inch) or replace the spark plug. Check that

the spark plug is tted with a suppressor.

● Clean the outside of the carburetor and the space

around it.

● Check that the bevel gear is lled three-quarters full

with lubricant. Fill if necessary using special grease.

● Check the fuel lter from contamination and the

fuel hose from cracks or other defects. Replace if

necessary.

● Check all cables and connections.

● Check the clutch, clutch springs and the clutch

drum for wear. Replace if necessary by an

authorized service workshop.

● Replace the spark plug. Check that the spark plug

is tted with a suppressor.

● Clean or replace the spark arrestor mesh on the

mufer.

Loading...

Loading...