− 38 −

In addition, there are the following error codes in this device. These error codes interlock (or limit function) and inform the problem so

that the problem is not enlarged when any problem is discovered. When you request our service, please confirm the error codes.

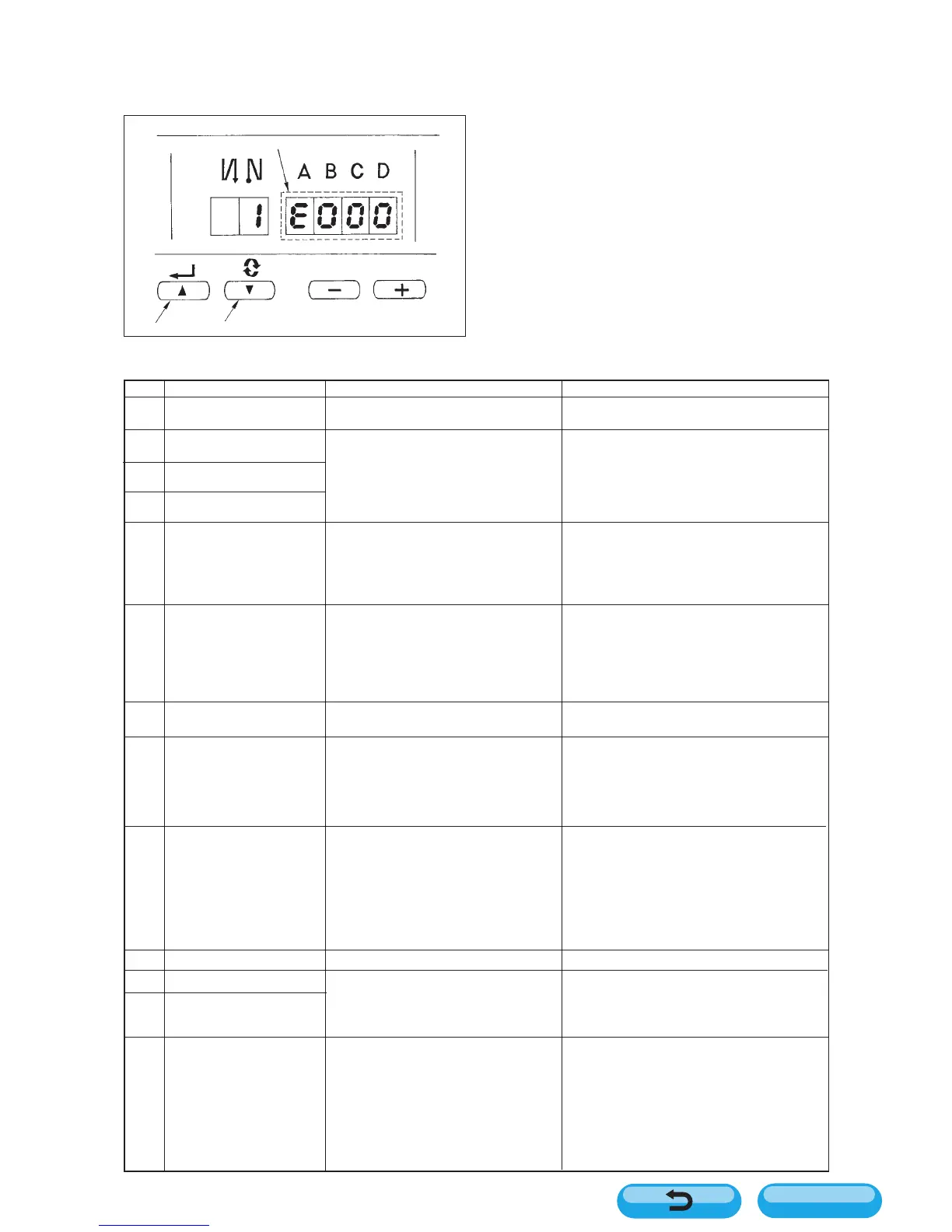

Checking procedure of the error code

1) Pressing switch 1 in the control box, turn ON the power switch.

2) LED becomes display 5 with the sound of “peep” and

the latest error code is displayed.

3) Confirmation of the contents of previous error can be

performed by operating switches 1 or 2.

(Caution) When operating switch 1, one before the

existing error code is displayed.

When operating switch 2, one after the existing

error code is displayed.

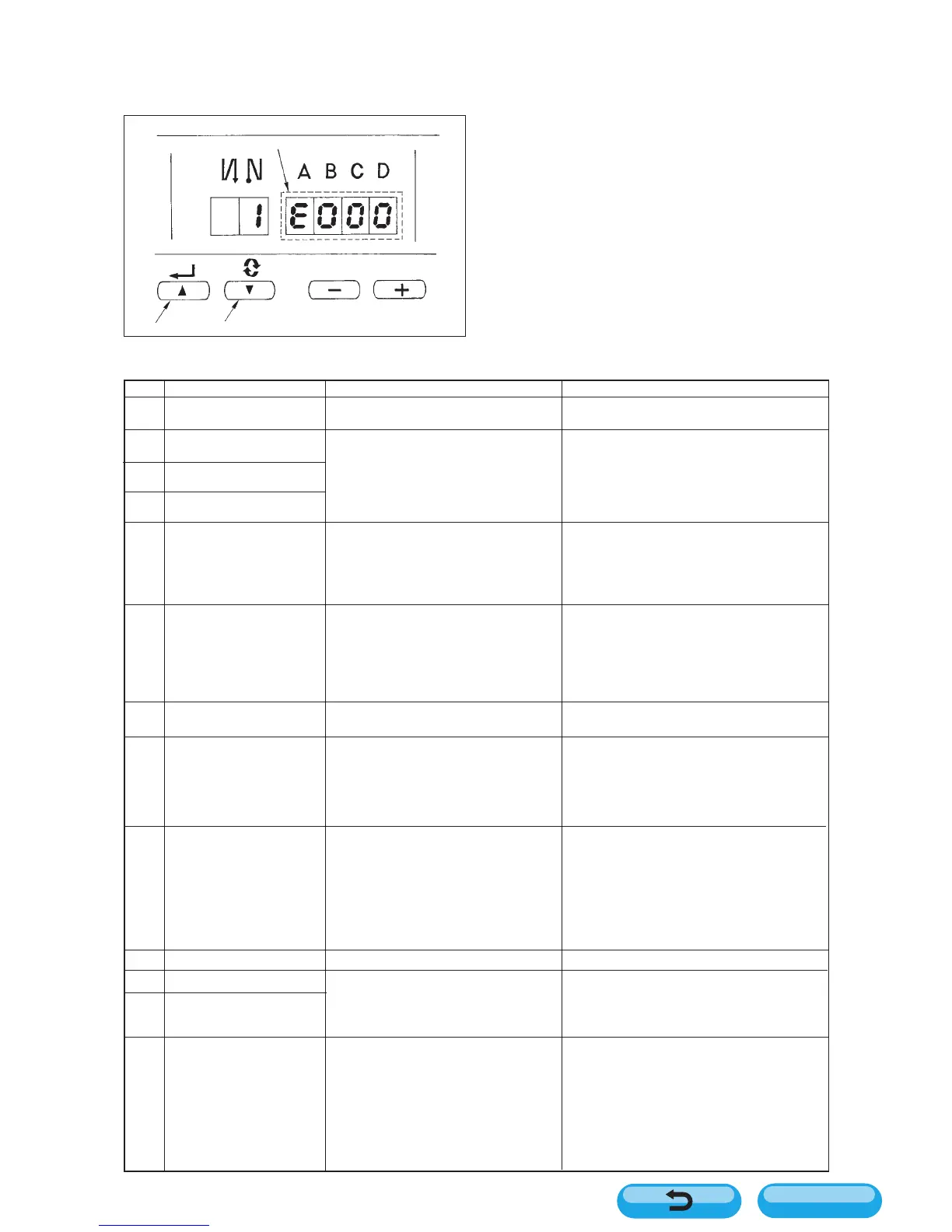

Error code list

No.

E000

E003

E004

E005

E906

E007

E008

E811

E813

E924

E730

E731

E343

Description of error detected

Execution of data initialization

(This is not the error.)

Disconnection of synchronizer

connector

Synchronizer lower position

sensor failure

Synchronizer upper position

sensor failure

Operation panel transmission

failure

Overload of motor

Machine head connector

failure(Resistance pack)

Overvoltage

Low voltage

Motor driver failure

Encoder failure

Motor hole sensor failure

Bobbin thread remaining

amount sensor unit failure

Cause of occurrence expected

• When the machine head is changed.

• When the initialization operation is executed

• When position detection signal is not input

from the sewing machine head

synchronizer.

• When the synchronizer has broken.

• Disconnection of operation panel cord

• Operation panel has broken.

• When the machine head is locked.

• When sewing extra-heavy material beyond

the guarantee of the machine head.

•When the motor does not run.

• Motor or driver is broken.

• When the machine head connector is not

properly read.

• When voltage higher than guaranteed one

is inputted.

• 220V has been inputted to SC-500 of 110V

specifications.

• 400V is applied to the box of 220V (230V).

• When voltage lower than guaranteed one

is inputted.

• 110V has been inputted to SC-500 of 220V

specifications.

• 110V is applied to the box of 220V.

• Inner circuit is broken by the applied

overvoltage

• Motor driver has broken.

• When the motor signal is not properly

inputted.

• When the position of the detection bar of

the AE device is shifted from the home

position.

Items to be checked

• Check the synchronizer connector (CN33) for

loose connection and disconnection.

• Check whether the synchronizer cord has broken

since the cord is caught in the machine head.

• Check the operation panel connector (CN38) for

loose connection and disconnection.

• Check whether the operation panel cord has

broken since the cord is caught in the machine

head.

• Check whether the thread has been entangled in

the motor pulley.

• Check the motor output connector (4P) for loose

connection and disconnection.

• Check whether there is any holdup when turning

the motor by hand.

• Check the machine head connector (CN32) for

loose connection and disconnection.

• Check whether the applied power voltage is higher

than the rated voltage + (plus) 10% or more.

• Check whether 110V/220V changeover switch is

improperly set.

In the aforementioned cases, POWER p.c.b is

broken.

• Check whether the voltage is lower than the rated

voltage – (minus) 10% or less.

• Check whether 110V/220V changeover switch is

improperly set.

• Check whether fuse or regenerative resistance is

broken.

• Check the motor signal connector (CN30) for loose

connection and disconnection.

• Check whether the motor signal cord has broken

since the cord is caught in the machine head.

• Check whether the detection bar of the AE device

has returned to the correct position.

• Check whether the function setting No. 57 has

been mistakenly set.

• Check the AE device connectors (CN121, CN123)

for loose connection and disconnection.

• Check whether the AE device cord has broken

since the cord is caught in the machine head.

5

1

2

Contents

Loading...

Loading...