– 3 –

5. ATTACHING THE NEEDLE

6.

SETTING THE BOBBIN INTO THE BOBBIN CASE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

Use the specied needle for the machine. Use the proper needle in accordance with the thickness of thread used and the kinds of the materials.

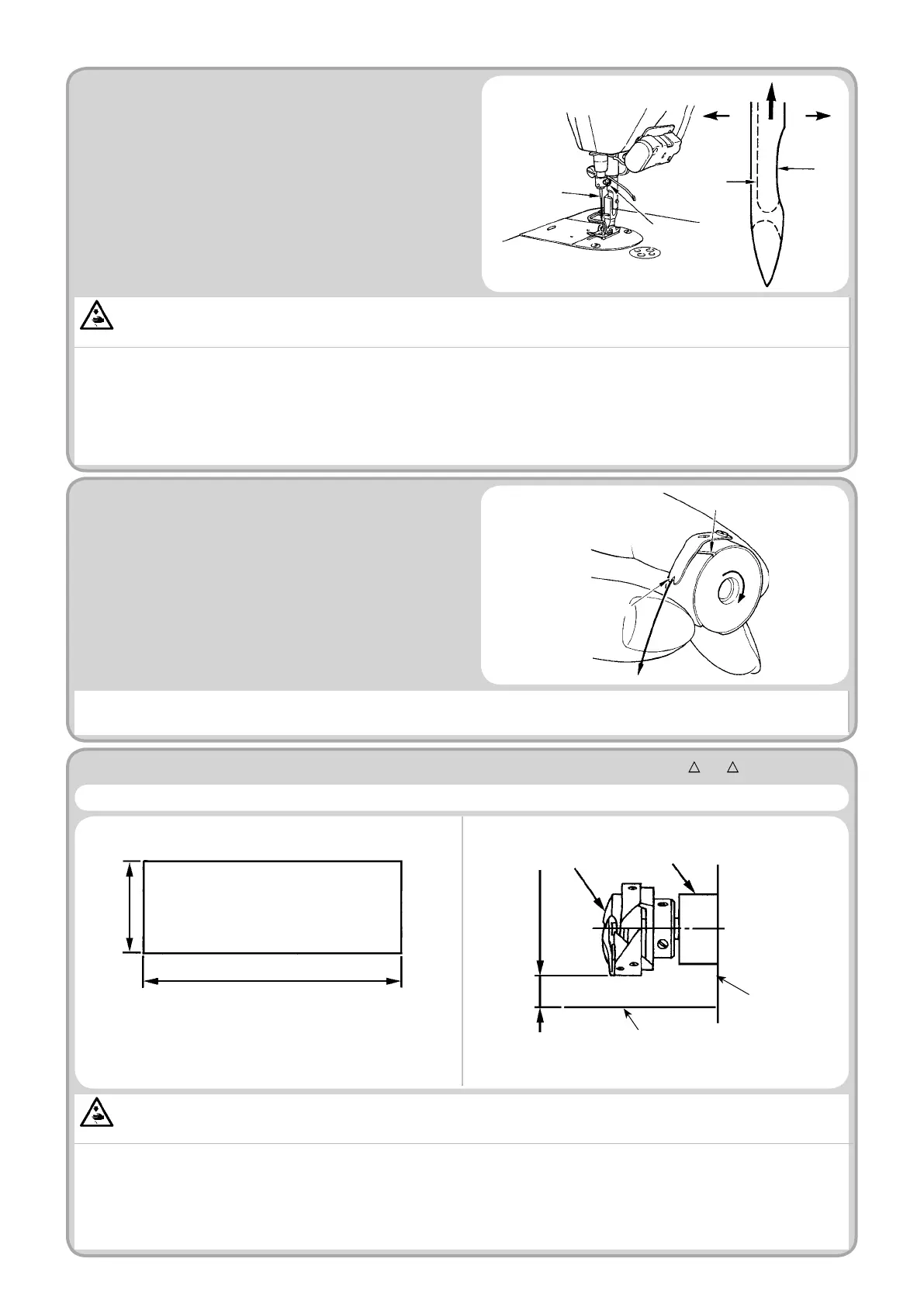

1) Turn the handwheel until the needle bar reaches the highest point of its stroke.

2) Loosen screw

2

, and hold needle

1

with its indented part

A

facing exactly to the right in direction

B

.

3) Insert the needle fully into the hole in the needle bar in the direction of the arrow until the end of hole is reached.

4) Securely tighten screw

2

.

5) Check that long groove

C

of the needle is facing exactly to the left in direction

D

.

(Caution) When polyester lament thread is used, if the indented part of the needle is tilted toward operator's side, the loop of thread becomes

unstable. As a result, hangnail of thread or thread breakage may occur. For the thread that such phenomenon is likely to occur, it is effective to

attach the needle with its indented part slightly slanting on the rear side.

1

2

C

D

B

A

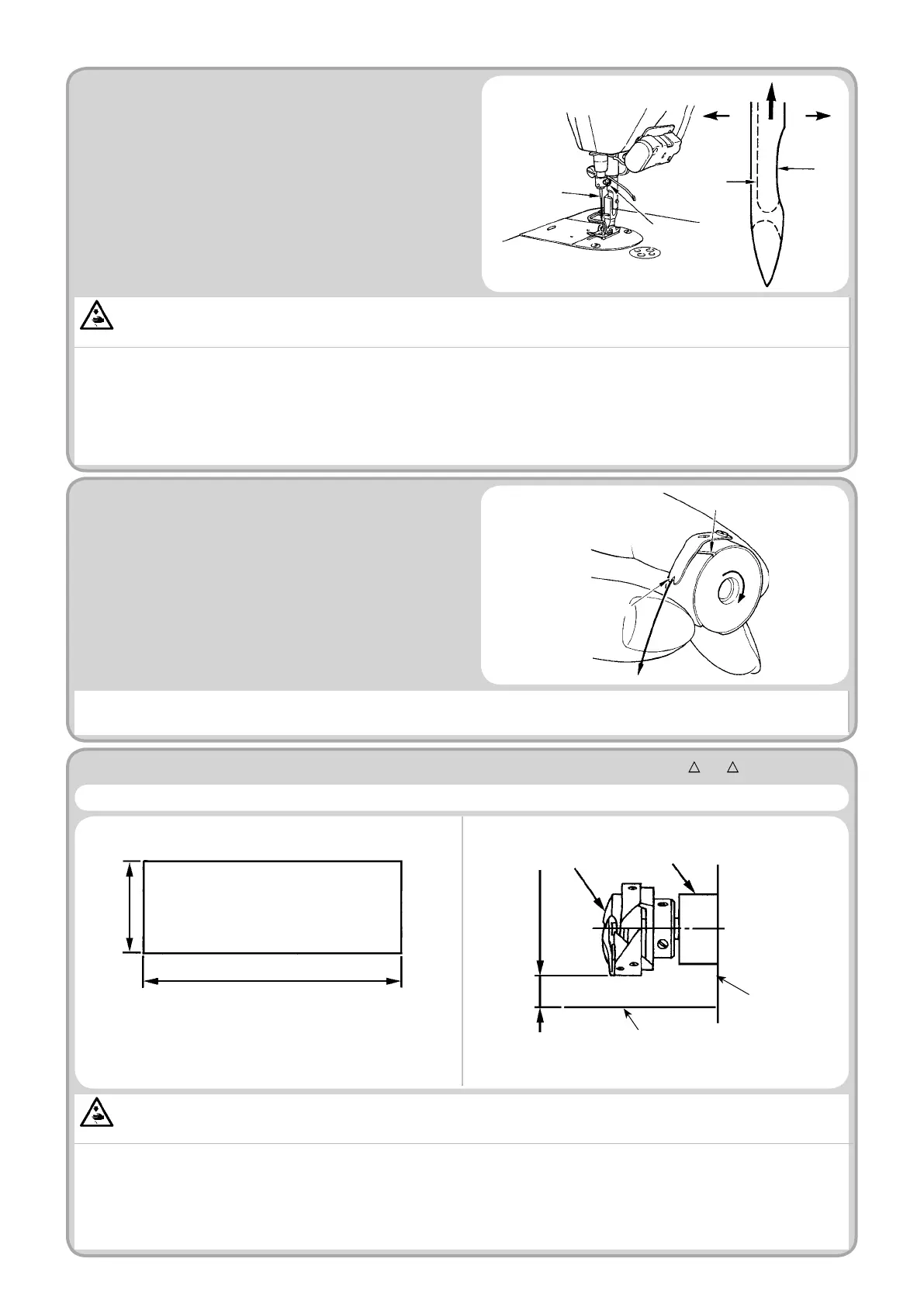

1) Install the bobbin in the bobbin case so that the thread wound direction is clockwise.

2) Pass the thread through thread slit

A

, and pull the thread in direction

C

. By so doing, the thread will pass under the tension spring and come out from notch

B

.

3) Check that the bobbin rotates in the direction of the arrow when thread is pulled.

A

B

C

(1) How to conrm the amount of oil (oil splashes)

7.ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK (DDL-9000B-S , -M )

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked by turning the hook at a high speed.

* When carrying out the procedure described below in 2), conrm the state that the needle thread from the thread take-up lever to the needle

and the bobbin thread are removed, the presser foot is lifted and the slide plate is removed. At this time, take extreme caution not to allow your

ngers to come in contact with the hook.

1) If the machine has not been sufciently warmed up for operation, make the machine run idle for approximately three minutes. (Moderate intermittent

operation)

2) Place the amount of oil (oil splashes) conrmation paper under the hook while the sewing machine is in operation.

3) Conrm that oil exists in the oil tank.

4) Conrmation of the amount of oil should be completed in ve seconds. (Check the period of time with a watch.)

2

Position to conrm the amount of oil (oil splashes)

Closely t the paper against

the wall surface of the bed.

Hook

Hook driving shaft front bushing

Bed

Oil splashes conrmation paper

3 - 10 mm

* Place the amount of oil (oil splashes) conrmation paper under the

hook and keep it from the hook by 3 to 10 mm to conrm the amount.

1

Amount of oil (oil splashes) conrmation paper

* Use any paper available regardless of the material.

Approx. 70 mm

Approx. 25 mm

Loading...

Loading...