−37 −

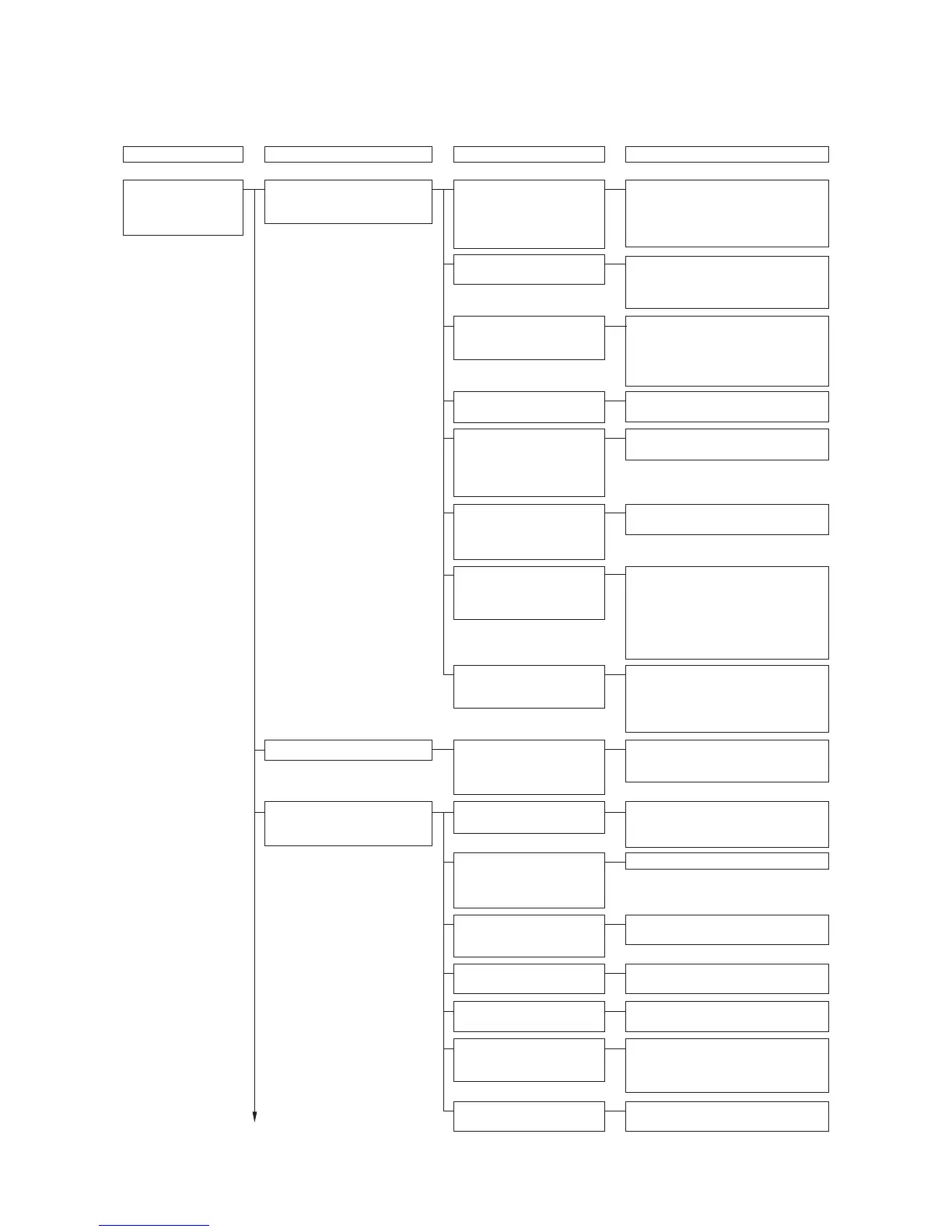

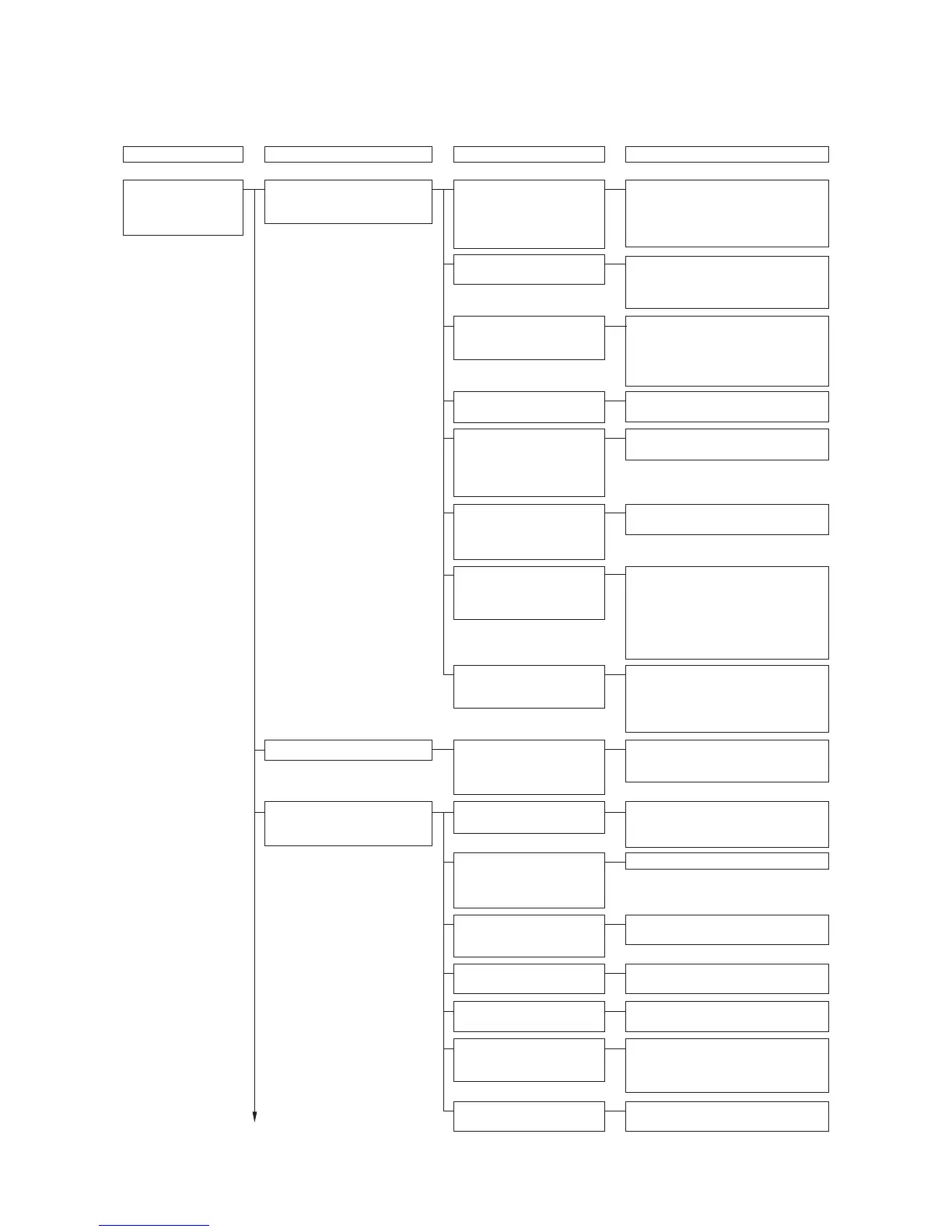

7. TROUBLES AND CORRECTIVE MEASURES

(1) With regard to mechanical components

1. Stitch skipping of 1 to

several stitches

occurs at the start of

sewing.

1-1) Needle thread remaining on

the needle tip after thread

trimming is too short.

1-2) Needle used is improper.

1-3) Needle thread is not caught

at the blade point of hook.

(Stitch skipping)

1)-A Needle thread path is

abnormal and needle

thread resistance at the

time of thread trimming is

strong.

1)-B Tension of thread tension

No. 1 is too high.

1)-C Rising amount of tension

disk No. 2 at the time of

thread trimming is small.

1)-D Thread trimming timing is

too early.

1)-E receding amount of

moving knife is

insufficient and needle

thread is not caught in the

thread-draw of knife unit.

1)-F Counter knife is

excessively near to

needle.

Blade tip is too sharp.

1)-G There are scratches on

knife thread guide,

moving knife, hook, and

thread-draw.

1)-H Stroke or tension of

thread take-up spring is

too large or too high.

2)-A Thread is not held and apt

to slip off since needle

hole of material does not

recover.

3)-A Timing between hook and

needle is improper.

3)-B Clearance between hook

and needle when needle

thread is caught is too

large.

3)-C Stroke or tension of

thread take-up spring is

too large or too high.

3)-D Worn-out of blade point of

hook.

3)-E Installation of needle is

improper.

3)-F Position where needle

thread is caught is

improper.

3)-G Pressure of presser foot

is too low and cloth flops.

Check the inside of needle thread paths

such as thread tangling or orientation of

thread guide bar, position (height) and

orientation (twist) of thread stand, mistake

of threading at each section, etc.

Decrease tension of thread tension No. 1

within the range where rough motion of

thread does not occur between thread

tensions No. 1 and No. 2.

Correct the rising amount of the disk

according to 4-(9). In addition, when the

disk is obliquely rising, turn 180fl the

thread tension No. 2 spring or correct the

inclination of the spring.

Correct the thread trimmer cam timing

according to 4-(6).

Correct the receding amount of moving

knife according to 4-(4).

Check and adjust the position, shape,

etc. of counter knife according to 4-(7).

Check the hook (especially, blade point

and blade), edge of knife thread guide,

moving knife (especially, thread catching

section), and scratch of thread draw-out.

If there is a scratch, polish it with buff.

When the scratch is large, replace the

part.

Adjust the stroke or the tension to a

proper one.

Aim of the machine is as follows.

Stroke : 8 mm

Tension : 0.2N

Use a needle which is as thin as

possible to adjust it to cloth or thread

count.

Correct the hook timing (aim of return

amount : 1.8 mm) according to the 4-(2).

(Use the gauge supplied as accessories.)

Correct the clearance to 0 to 0.06 mm.

Adjust the stroke to a proper one (8 mm)

or the tension to a proper one (0.2N).

Correct the blade point or replace the

hook.

Adjust the inclination of needle. (Replace

the needle when it is bent.)

Adjust the height of the needle. (Refer to

4.- (1).)

Check whether the needle is fully

inserted.

Adjust the pressure of the presser foot

according to the Instruction Manual.

Cause (1)

Troubles

Cause (2) Corrective measures

To the next page

Loading...

Loading...