−41 −

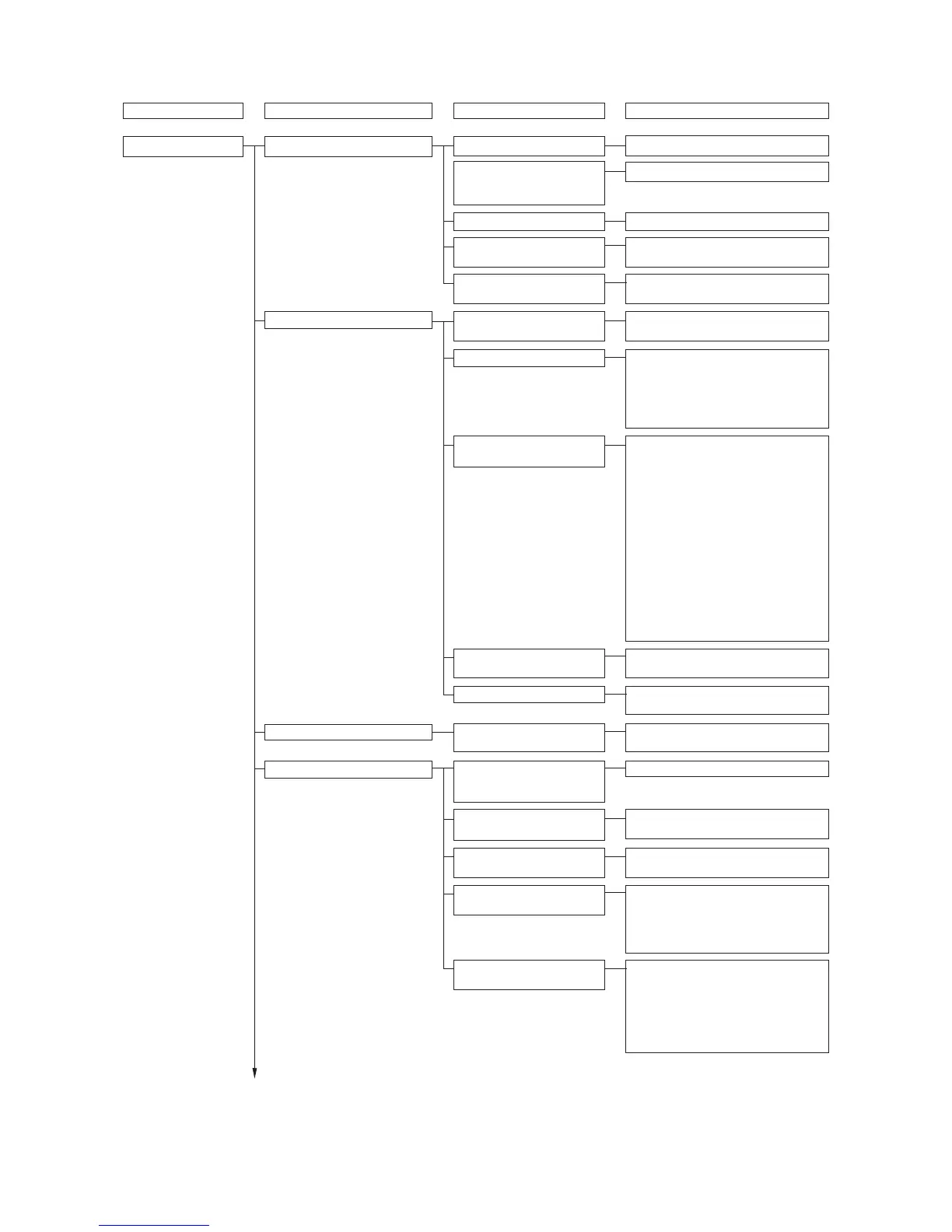

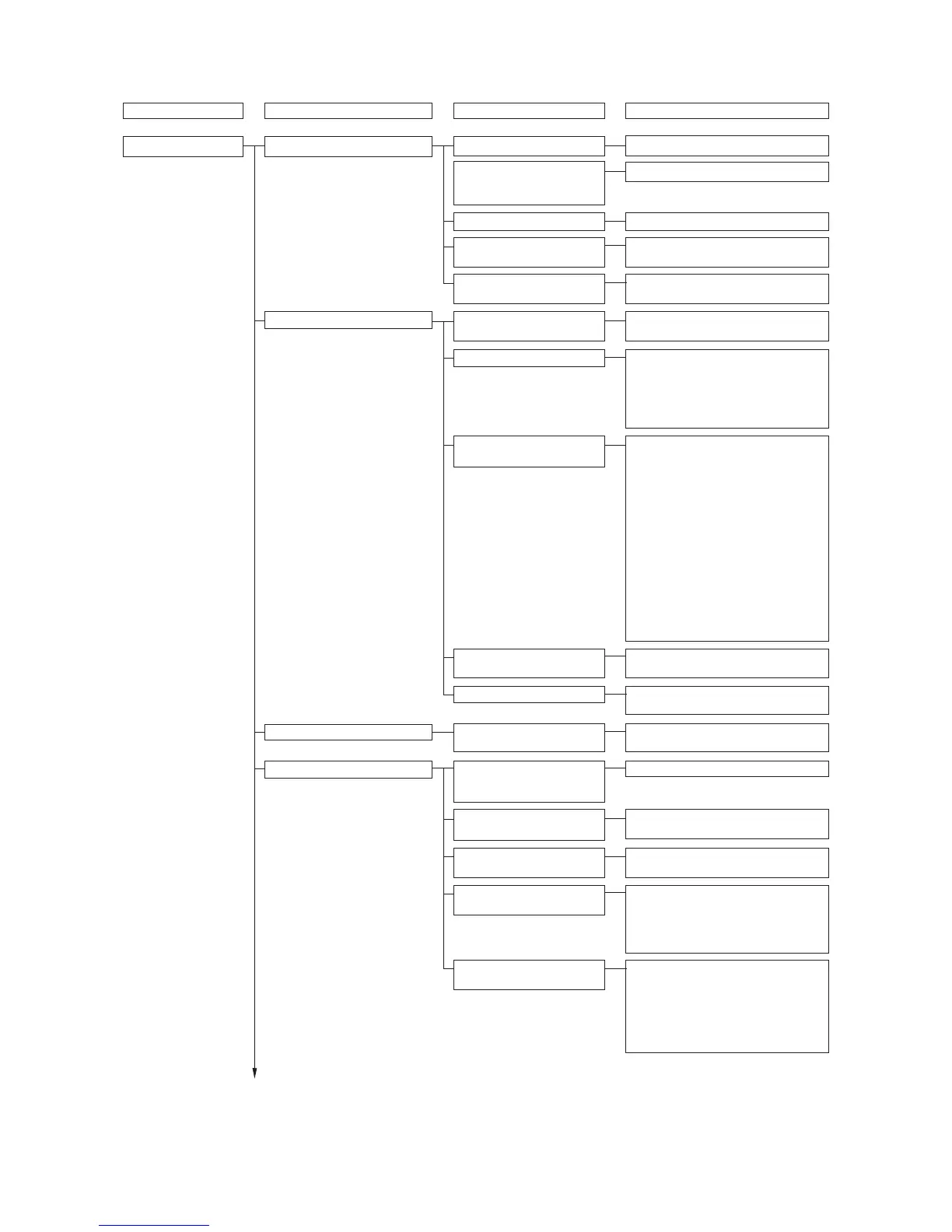

(2) With regard to sewing

Cause (1)Troubles

Cause (2)

Corrective measures

To the next page

1. Stitch skipping 1-1) Needle components

1-2) Hook components

1-3) Defective feed

1-4) Thread tension components

1)-A Needle is bent.

1)-B Installation of needle is

wrong. (Orientation or

insufficient insertion)

1)-C Blunt of needle tip

1)-D Needle is too thin for

thread used or cloth.

1)-E Kind of needle is

improper.

2)-A Blunt or worn-out of

blade point of hook

2)-B Defective hook timing

2)-C Height of needle bar is

improper.

2)-D Clearance at blade point

of hook is improper.

2)-E No needle guard

3)-A Stitch skipping due to

stitch gathering

4)-A Needle thread tension is

too high. (excessively

tightened)

4)-B Tension of thread take-

up spring is too high.

4)-C Stroke of thread take-up

spring is too large

4)-D Stroke of thread take-up

lever is small.

4)-E Tension of thread tension

No. 1 is too low.

Replace the needle.

Install the needle again.

Replace the needle.

Replace the needle with a proper needle

(thick needle if possible).

Replace the needle with a proper one.

SCHMETZ UY180GVS is recommended.

Correct the blade point of hook or replace

the hook.

Adjust the timing according to 4-(2).

Perform the adjustment described in the

Instruction Manual as the aim and in

accordance with the conditions of cloth and

thread, perform fine adjustment according

to 4-(21).

Adjust the height of needle bar according

to 4-(1).

Making as the base the adjustment

procedure described in the Instruction

Manual, in accordance with the conditions

of cloth and thread, perform fine

adjustment according to 4-(21).

• When setting the needle bar rather in a

lower position, be careful of the needle

thread lock between needle and inner

hook needle guard at the lower dead

point of the needle bar.

• When setting the needle bar rather in a

higher position, be careful of the contact

between the blade point of hook and the

belly section of needle.

Make small the clearance between needle

and the blade point (Make it near to “0”.)

Especially, in case of thick materials, use

the designated hook with needle guard.

Refer to the item “Stitch gathering at

overlapped section”.

Decrease the tension.

Correct to the proper tension. (0.2N is

recommended.)

Correct to the proper stroke. (8 mm is

recommended.)

Correct to the proper stroke at the position

of arm thread guide A. (Position of marker

line is standard, and when moving

counterclockwise, stroke of thread take-up

lever is increased.)

Adjust the tension to such an extent that

thread does not move roughly between

thread tensions No. 1 and No. 2.

(However, when the tension of thread

tension No. 1 is excessively high, thread

trimming performance is affected. Do not

excessively increase the tension.)

Loading...

Loading...