– 8 –

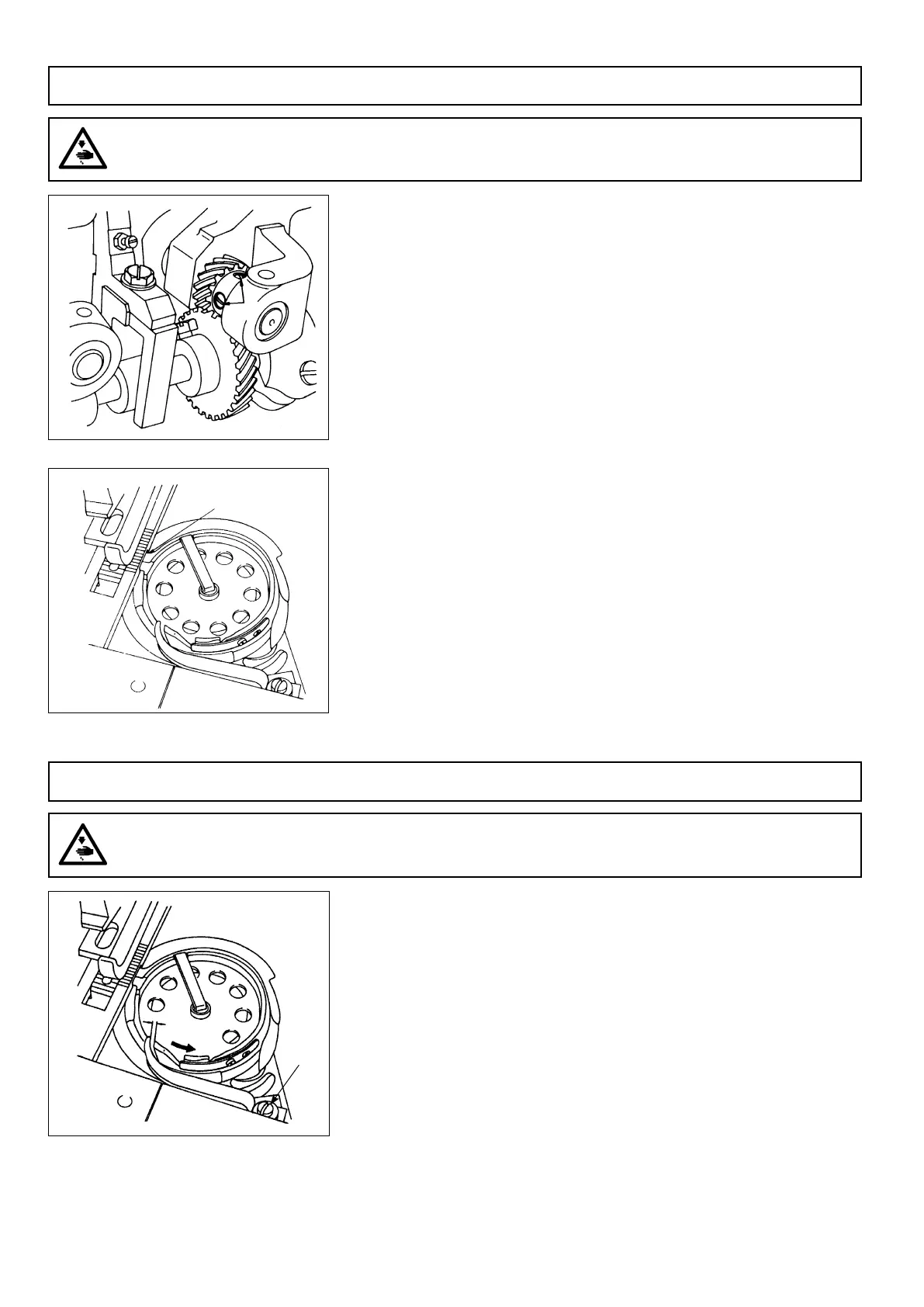

Rotate the handwheel toward the normal direction (with the bobbin case open-

er in rotated condition toward the arrow direction) and as shown in the fi gure,

when the bobbin case opening lever has retreated to the rearest position, loos-

en the clamp screw

❶

of the bobbin case opening lever and adjust so that the

clearance between the bobbin case opener and the bobbin case opening lever

comes to 0.3 - 0.4 mm (3/256 - 1/64”).

12. INSTALLING AND DISMANTLING THE SEWING HOOK

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

13. ADJUSTING THE BOBBIN CASE OPENING LEVER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

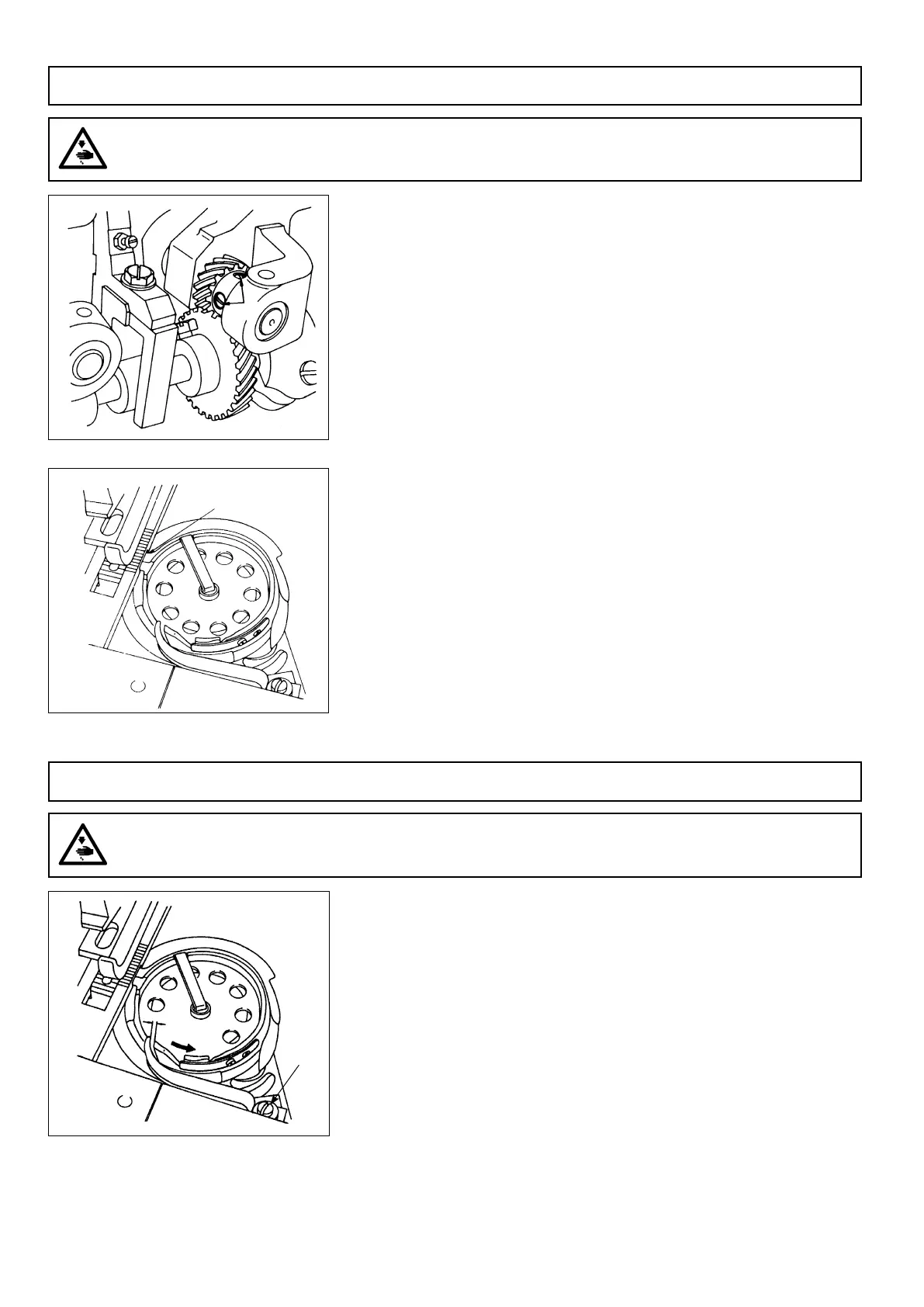

1. Dismantling the sewing hook

1) Remove the presser foot, walking foot, throat plate, feed dog and bobbin case

opening lever.

2) Tilt the machine and loosen the set screw

❶

of the small gear.

3) Rotate the handwheel to bring the needle bar to its highest position and re-

move the sewing hook by pulling it upwards.

(Note) At this point, be sure to see that the interlocking of the large gear

and the small gear is not slipping. (If the gears are marked, it will

help)

2. How to install the sewing hook

1) To install the sewing hook, reverse the dismantling procedure. In so doing,

watch the following:

* That the bobbin case opening lever link is inserted into the link pin.

* Make the No.1 set screw of the small gear (the fi rst screw seen when it is ro-

tated in normal direction) enter the V-groove of the sewing hook driving shaft.

2) In order that the protruding part of the bobbin case holder enters the groove

of the throat plate, rotate the bobbin case holder by the hand and after that,

set the throat plate.

0.3-0.4mm

❶

Protruding part

❶

– 1 –

SPECIFICATIONS

Model LG-158 LG-158-1

Type of sewing

machine head

2-needle, unison-feed lockstitch machine

(with a reverse-feed stitching function)

1-needle, unison-feed, lockstitch machine

(with a reverse-feed stitching function)

Usage For sewing extremely heavy weight & heavy weight materials

Sewing speed Max. 1,500 sti/min

Lift of presser foot Max. 16 mm

Stitch length 0

〜

10 mm

Needle DD x 1 #25 2 ea. DD x 1 #25 1 ea.

Reverse sewing By treading pedal

Needle gauge

3/4" (Standard), 1/4", 5/16", 3/8", 1/2", 5/8", 7/8",

1", 1-1/4", 1-1/2", 2", 2-1/4", 2-1/2"

-

Lubricating oil JUKI New Defrix Oil No. 1

Noise

- Equivalent continuous emission sound pressure

level (L

pA

) at the workstation:

A-weighted value of 87.5 dB; (Includes K

pA

= 2.5

dB); according to ISO 10821- C.6.2 - ISO 11204

GR2 at 1,500 sti/min.

- Sound power level (L

WA

);

A-weighted value of 97.5 dB; (Includes K

WA

= 2.5

dB); according to ISO 10821- C.6.2 - ISO 3744

GR2 at 1,500 sti/min.

- Equivalent continuous emission sound pressure

level (L

pA

) at the workstation:

A-weighted value of 87.5 dB; (Includes K

pA

= 2.5

dB); according to ISO 10821- C.6.2 - ISO 11204

GR2 at 1,500 sti/min.

- Sound power level (L

WA

);

A-weighted value of 96.5 dB; (Includes K

WA

= 2.5

dB); according to ISO 10821- C.6.2 - ISO 3744

GR2 at 1,500 sti/min.

1. INSTALLING THE MACHINE

1) When carrying the sewing machine, be sure to carry by two

people.

(Caution) Do not hold the pulley.

2) Do not place a protruding object, such as a screw driver, at

a place where the sewing machine is to be installed.

3) Fix the oil pan supplied with the machine on the table in 10

placed with nails.

Set the oil pan so that its U-shaped notch is brought to the

opposite side of the operator.

4) Attaching the hinge arm

Install hinge arms

❶

to the front and rear (at one location

each) of the sewing machine head with screws

❷

. Hook

hinge seats

❸

on hinge arms

❶

.

(When hooking hinge seats

❸

on the hinge arms

❶

, face

the counter sunk plane of the hinge seats

❸

upward.)

❸

❷

❶

2mm 2mm

30mm

Loading...

Loading...