i

i

For the sewing machine, automatic machine and ancillary devices (hereinafter collectively referred to as

"machine"), it is inevitable to conduct sewing work near moving parts of the machine. This means that there

is always a possibility of unintentionally coming in contact with the moving parts. Operators who actually

operate the machine and maintenance personnel who are involved in maintenance and repair of the machine

are strongly recommended to carefully read to fully understand the following

SAFETY PRECAUTIONS

before using/maintaining the machine. The content of the

SAFETY PRECAUTIONS

includes items which

DUHQRWFRQWDLQHGLQWKHVSHFL¿FDWLRQVRI\RXUSURGXFW

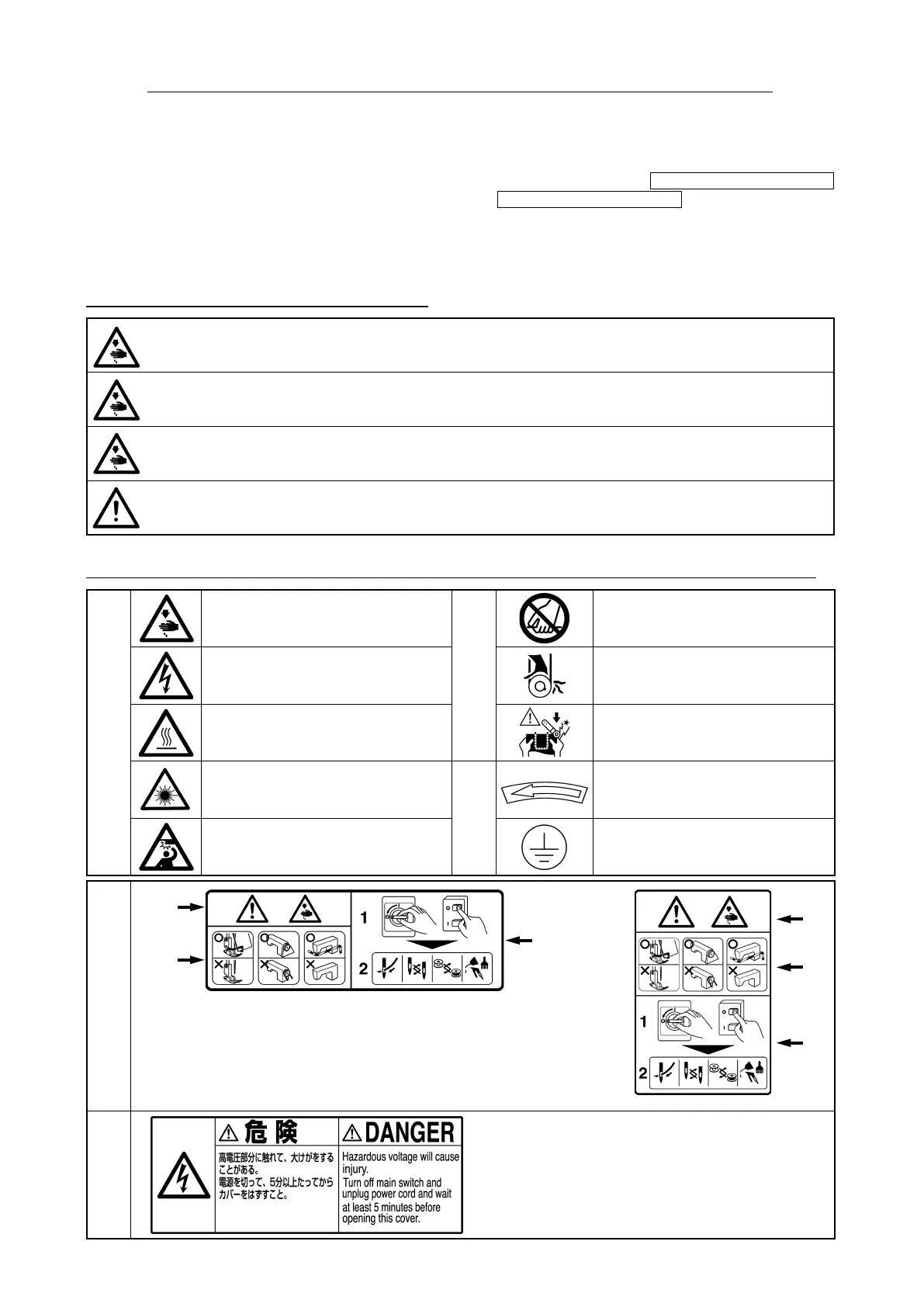

7KHULVNLQGLFDWLRQVDUHFODVVL¿HGLQWRWKHIROORZLQJWKUHHGLIIHUHQWFDWHJRULHVWRKHOSXQGHUVWDQGWKHPHDQLQJ

of the labels. Be sure to fully understand the following description and strictly observe the instructions.

Warning label

❶

❷

❸

❶

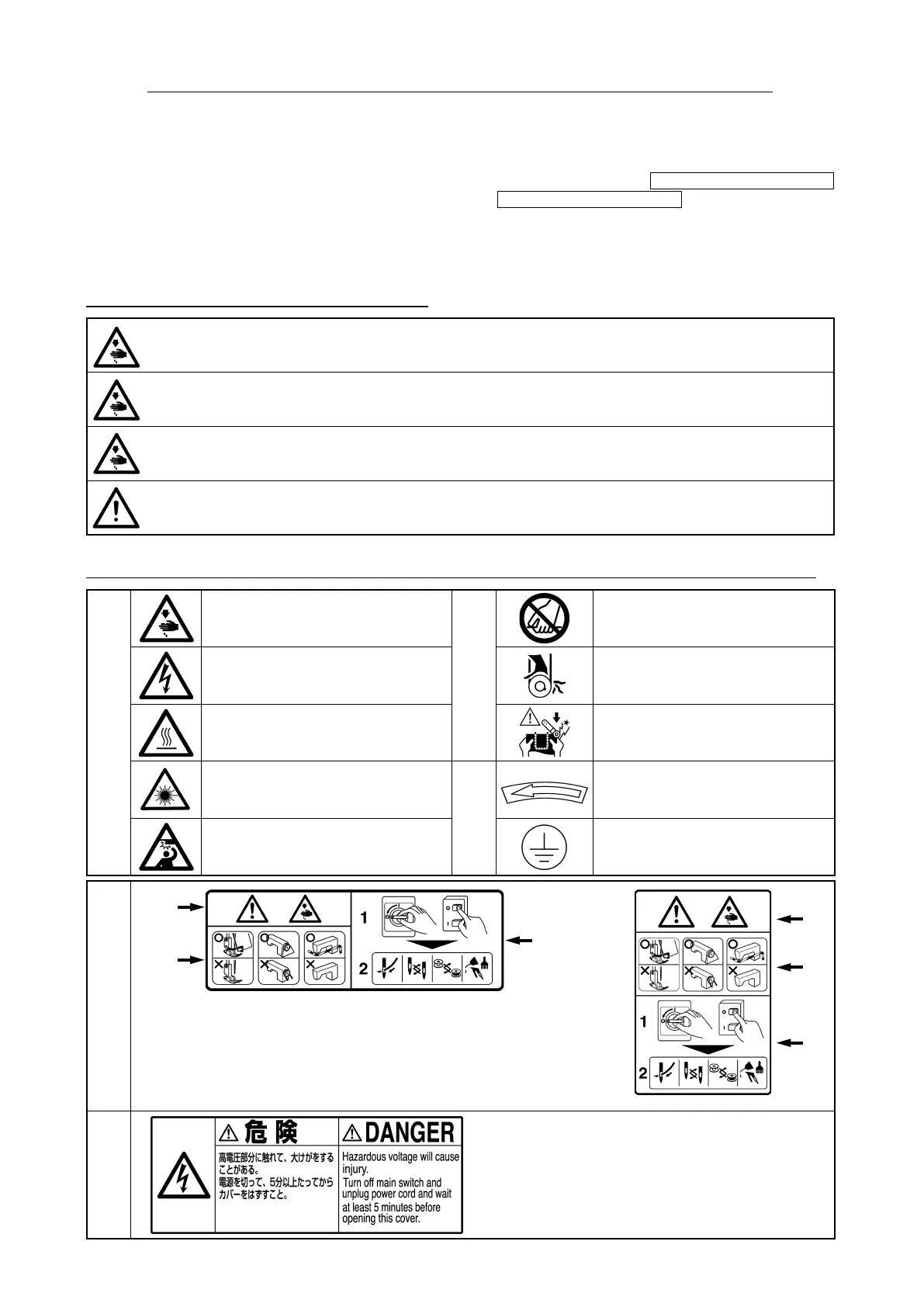

7KHUHLVWKHSRVVLELOLW\WKDWVOLJKWWRVHULRXVLQMXU\RUGHDWKPD\EHFDXVHG

7KHUHLVWKHSRVVLELOLW\WKDWLQMXU\PD\EHFDXVHGE\WRXFKLQJPRYLQJSDUW

❷

7RSHUIRUPVHZLQJZRUNZLWKVDIHW\JXDUG

7RSHUIRUPVHZLQJZRUNZLWKVDIHW\FRYHU

7RSHUIRUPVHZLQJZRUNZLWKVDIHW\SURWHFWLRQGHYLFH

❸

%HVXUHWRWXUQWKHSRZHU2))EHIRUHFDUU\LQJRXWPDFKLQHKHDGWKUHDGLQJ

QHHGOHFKDQJLQJEREELQFKDQJLQJRURLOLQJDQGFOHDQLQJ

❸

❷

❶

(OHFWULFDOVKRFN

GDQJHUODEHO

DANGER :

7KLVLQGLFDWLRQLVJLYHQZKHUHWKHUHLVDQLPPHGLDWHGDQJHURIGHDWKRUVHURXVLQMXU\LIWKHSHUVRQLQFKDUJHRUDQ\WKLUG

SDUW\PLVKDQGOHVWKHPDFKLQHRUGRHVQRWDYRLGWKHGDQJHURXVVLWXDWLRQZKHQRSHUDWLQJRUPDLQWDLQLQJWKHPDFKLQH

WARNING :

7KLVLQGLFDWLRQLVJLYHQZKHUHWKHUHLVDSRWHQWLDOLW\IRUGHDWKRUVHULRXVLQMXU\LIWKHSHUVRQLQFKDUJHRUDQ\WKLUG

SDUW\PLVKDQGOHVWKHPDFKLQHRUGRHVQRWDYRLGWKHGDQJHURXVVLWXDWLRQZKHQRSHUDWLQJRUPDLQWDLQLQJWKHPDFKLQH

CAUTION :

7KLVLQGLFDWLRQLVJLYHQZKHUHWKHUHLVDGDQJHURIPHGLXPWRPLQRULQMXU\LIWKHSHUVRQLQFKDUJHRUDQ\WKLUGSDU

W\PLVKDQGOHVWKHPDFKLQHRUGRHVQRWDYRLGWKHGDQJHURXVVLWXDWLRQZKHQRSHUDWLQJRUPDLQWDLQLQJWKHPDFKLQH

,WHPVUHTXLULQJVSHFLDODWWHQWLRQ

3LFWRULDOZDUQLQJLQGLFDWLRQ

7KHUHLVDULVNRILQMXU\LIFRQWDFW

LQJDPRYLQJVHFWLRQ

3LFWRULDOZDUQLQJ

LQGLFDWLRQ

%HDZDUHWKDWKROGLQJWKHVHZLQJ

PDFKLQHGXULQJRSHUDWLRQFDQ

KXUW\RXUKDQGV

7KHUHLVDULVNRIHOHFWULFDOVKRFNLI

FRQWDFWLQJDKLJKYROWDJHVHFWLRQ

7KHUHLVDULVNRIHQWDQJOHPHQWLQ

WKHEHOWUHVXOWLQJLQLQMXU\

7KHUHLVDULVNRIDEXUQLIFRQWDFW

LQJDKLJKWHPSHUDWXUHVHFWLRQ

7KHUHLVDULVNRILQMXU\LI\RX

WRXFKWKHEXWWRQFDUULHU

%HDZDUHWKDWH\HGH¿FLHQF\FDQ

EHFDXVHGE\ORRNLQJGLUHFWO\DWWKH

ODVHUEHDP

,QGLFDWLRQODEHO

7KHFRUUHFWGLUHFWLRQLVLQGLFDWHG

7KHUHLVDULVNRIFRQWDFWEHWZHHQ

\RXUKHDGDQGWKHVHZLQJPD

FKLQH

&RQQHFWLRQRIDHDUWKFDEOHLV

LQGLFDWHG

TO ENSURE SAFE USE OF YOUR SEWING MACHINE

,([SODQDWLRQRIULVNOHYHOV

(II)

([SODQDWLRQRISLFWRULDOZDUQLQJLQGLFDWLRQVDQGZDUQLQJODEHOV

– 15 –

Problems Causes Corrective measures

⑤

Height of needle bar is not matched.

⑥

When skip-stitches occur at step-sewing

part.

⑦

When the blade point of the sewing hook

is crushed.

⑧

When the needle is defective.

○ When the needle bar is at lowest point make

the distance between the bottom of needle

clamp and upper surface of throat plate to 21.

2 mm (53/64").

○ Increase the alternate lifting amount of the

presser foot.

○ Remove the sewing hook and repair with a fi ne

mesh oil whetstone or exchange the hook with

a new sewing hook.

○ Exchange with a new needle.

3. Stitching fl aw.

①

The bobbin thread is not passing the

center of the thread tension spring of

bobbin case holder.

②

The outer rim of the bobbin is not smooth.

③

When the thickness of the needle is not

matched with the using thread.

④

When the supply of oil to the sewing hook

is not adequate.

⑤

Bobbin thread tension is too weak.

○ Make the bobbin thread to pass the center of

the tension spring.

○ Exchange the bobbin or polish the outer rim of

the bobbin with a fi ne mesh paper fi le. (sand

paper).

○ Exchange with an appropriate thick needle.

○ Refer to the chapter on

"3. LUBRICATION"

.

○ Refer to the chapter on

"8. THREAD

TENSION"

.

a. In case of stitching

fl aw due to change

of sewing speed.

①

Pressure of take-up spring is too weak.

②

Timing of bobbin case opening lever is

not matched.

③

Finish of thread paths of all parts are bad.

④

Sewing hook is defective.

○ Make the strength of take-up spring stronger.

(Refer to the chapter on

"8. THREAD

TENSION"

○ Refer to the chapter on

"13. ADJUSTING THE

BOBBIN CASE OPENING LEVER"

.

○ Polish with a fi ne mesh paper fi le (sand paper)

or by buffi ng.

○ Exchange the sewing hook with a new hook.

4. On feed pitch error

a. In case feed pitch

is too big.

①

Pressing pressure of presser foot is too

weak.

○ Tighten the pressure regulating themb screw.

b. In case feed pitch

is too small.

①

Feed dog is too low.

②

Tension of needle thread and bobbin

thread is too strong.

○ Refer to the chapter on

"17. ADJUSTING THE

HEIGHT OF THE FEED DOG"

.

○ Refer to the chapter on

"8. THREAD

TENSION"

.

5. Isolated idling loops

are produced

①

Tension of the needle threa is too weak.

②

Timing of the bobbin case opening lever

is not matched.

(Pulling of the bobbin case opening lever

is insuffi cient)

○ Strengthen the tension of the needle thread.

○ Refer to the chapter on

"11. ADJUSTING THE

WALKING FOOT AND PRESSER FOOT"

.

6. Even with the safety

device in action, good

stitching condition can

not be attained.

①

When the safety device has not returned

to the correct position.

②

Due to the strong impact, sometimes the

timing belt slides by one pitch.

○ Bring the safety device to the correct position.

○ Refer to the chapter on the timing of the main

shaft and the hook shaft.

Loading...

Loading...