− 28 −

6. CORRECTIVE MEASURES FOR MECHANICAL FAILURES

(1) Defective stop motion

1) The sound of the stop motion is low, and the machine stops

before reaching the required position.

™ Decrease the clearance between the stitch adjusting cam

and the roller.

™ Decrease the tension of the clamping pressure spring.

™ Reduce the axial play of the needle driving pulley at the

time of stop motion.

(2) The button clamp does not go up.

1) The hook of the button clamp lifting link has worn out.

™ Replace the button clamp lifting with a new one.

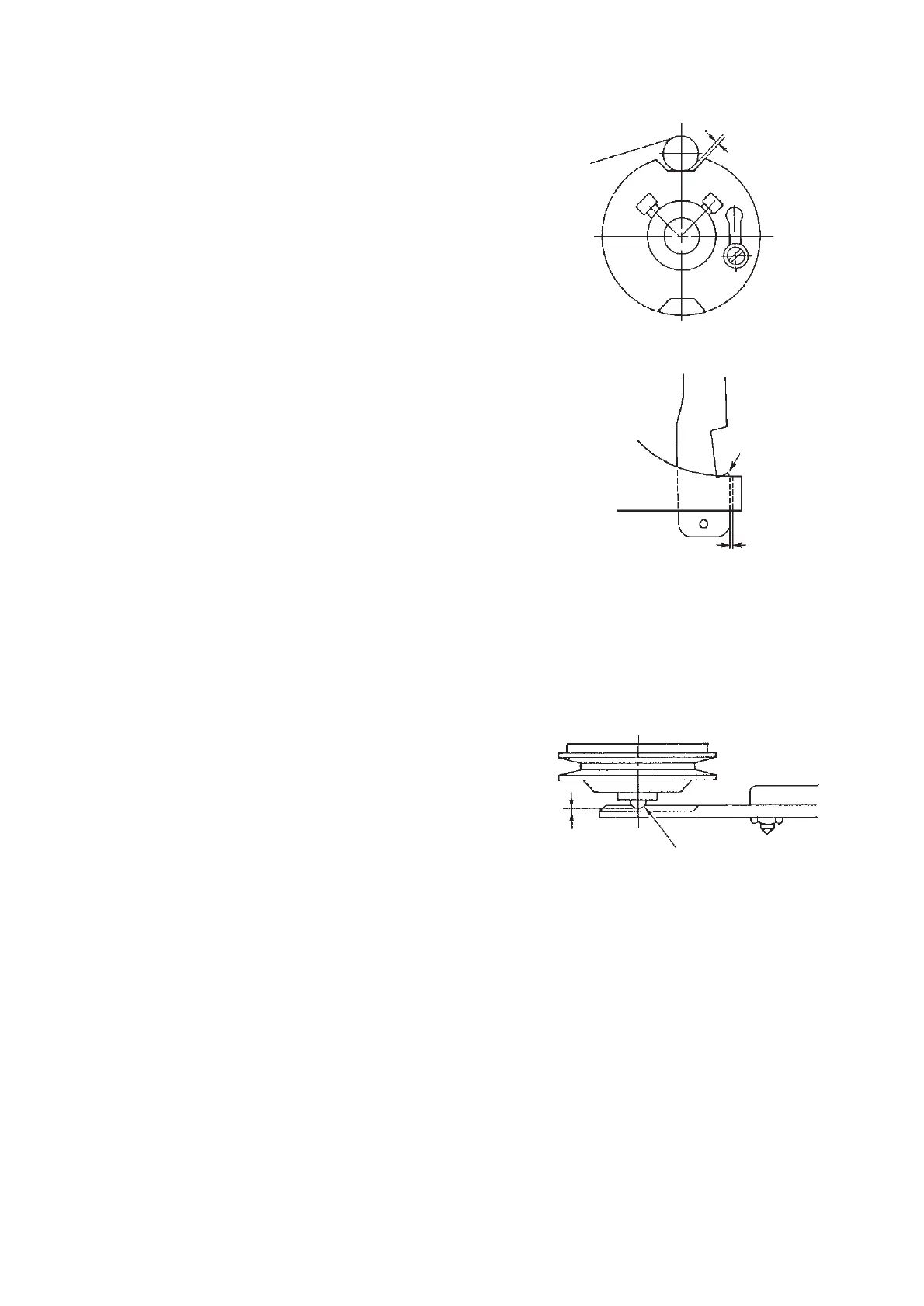

2) The clearance between the button clamp lifting link and the

button clamp forked rod is too large.

™ Correct it to 0.5 to 0.8 mm.

3) The clearance between the stitch adjusting cam and the roller

is too large.

™ Readjust it to 0.8 mm.

(3) The clutch of the needle driving pulley slips.

1) The driving ball and the needle driving pulley have worn out.

™ Replace the above two components, and the pulley insert.

2) Reduce the clearance between the driving ball and the needle

driving pulley pressure applying lever.

™ Readjust the clearance to 0.2 to 0.3 mm.

(4) The needle driving pulley is overheated, and the

starting pedal does not work smoothly.

1) Increase the clearance between the driving ball and the needle

driving pulley pressure applying lever.

0.8 mm

Hook

0.5 to 0.8 mm

0.2 to 0.3 mm

Driving ball