− 30 −

8.

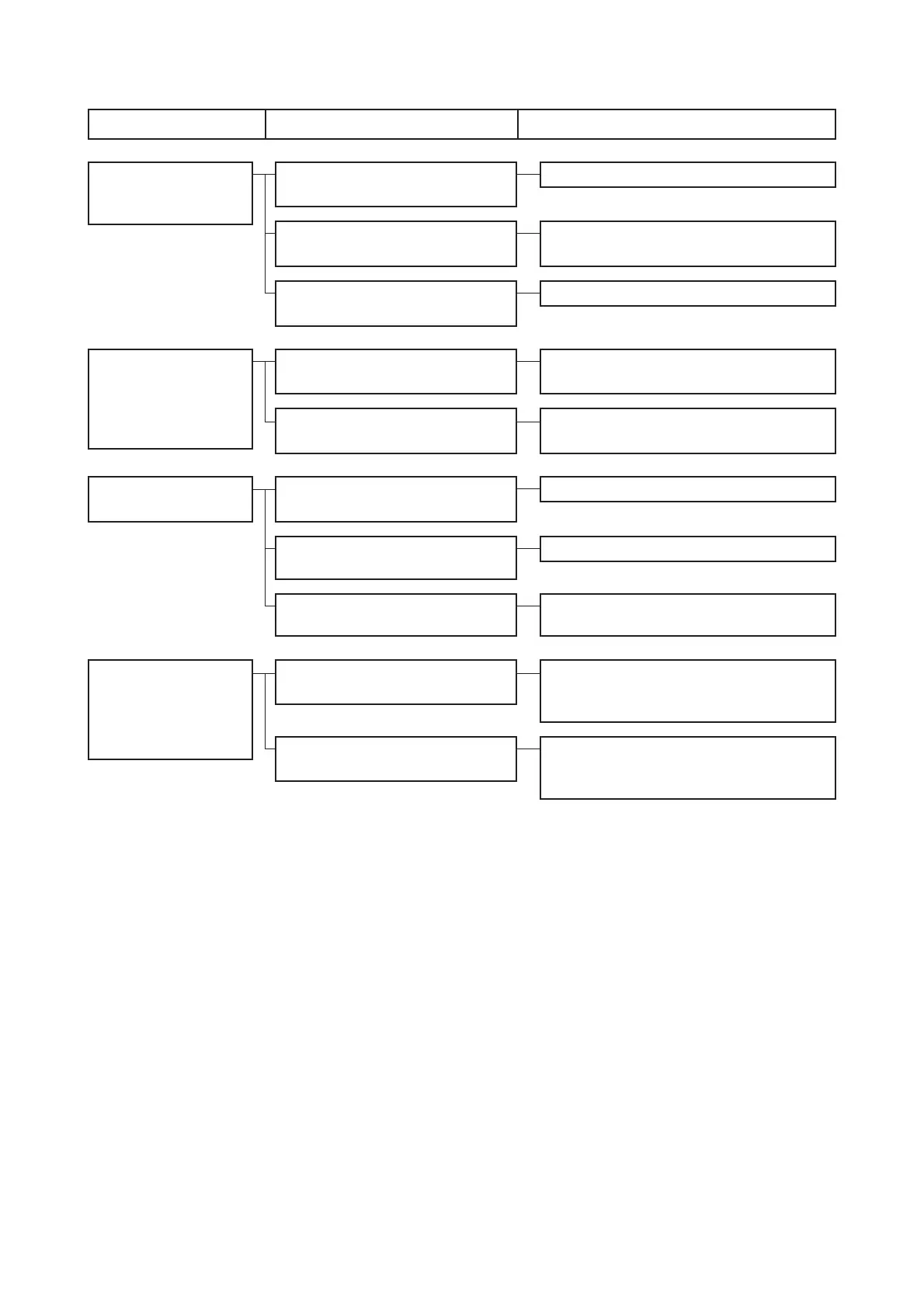

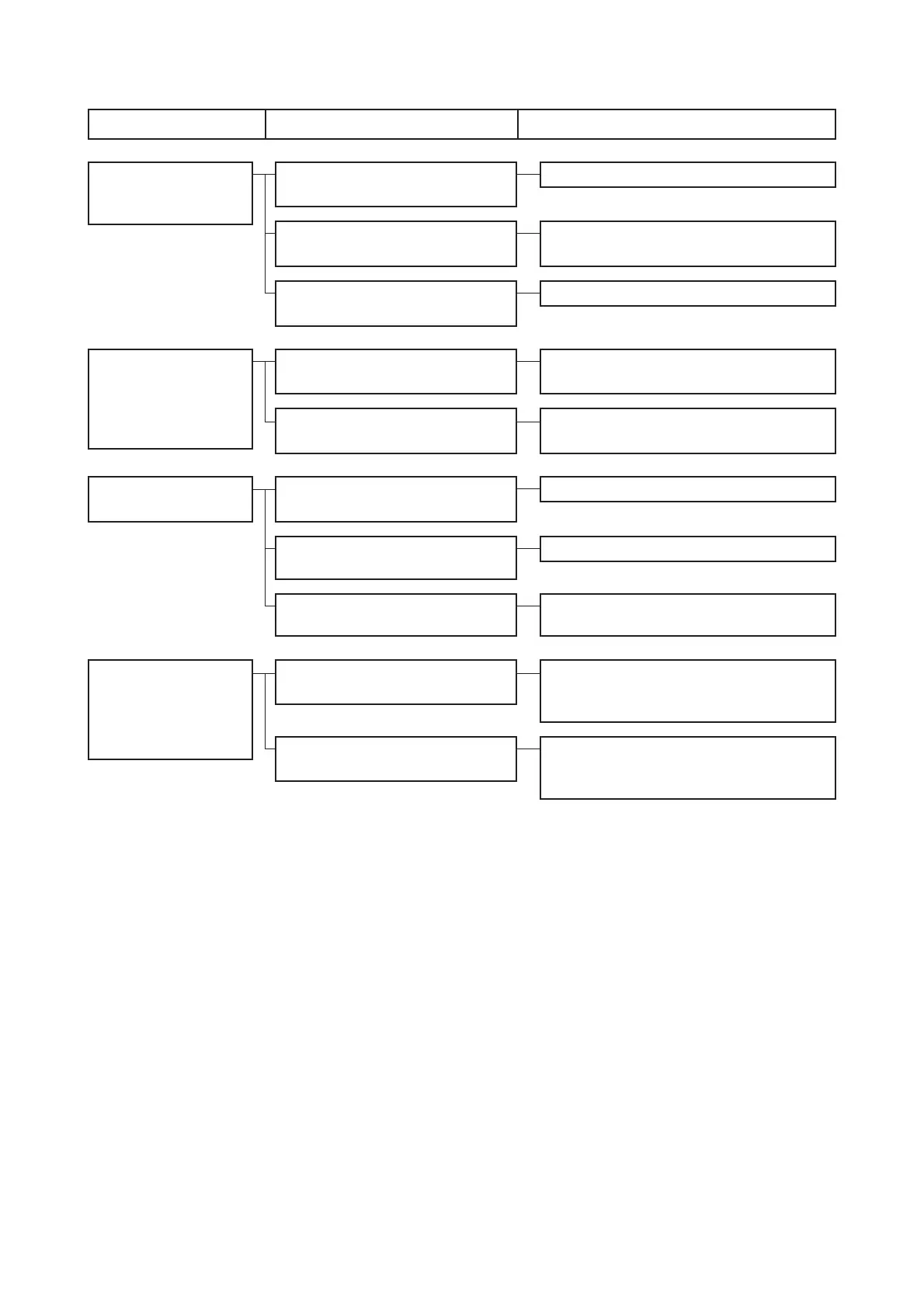

CAUSES OF TROUBLES AND THE CORRECTIVE MEASURES FOR MB-377

Troubles Causes Corrective measures

1. Needle thread breaks

after the machine

stops.

Lifting amount of the button clamp jaw

unit is excessive.

The nipper has been improperly

adjusted.

The thread pull-off lever has been

improperly adjusted.

Adjust the nipper with the nipper bar block.

Properly adjust the tension lever.

Adjust the lifting amount of the button clamp jaw

lever to 8 mm.

The tension lever has been improperly

adjusted.

Properly adjust the rocker shaft of the thread pull-

off lever.

2. The machine forms a

seam after it has run for

a while instead of

forming it from the start

of sewing.

Tension of the thread tension guide on

the face plate is excessive.

The tension lever has been improperly

adjusted.

Adjust the thread tension guide on the face plate

so that it provides a lower tension.

Properly adjust the tension lever.

Adjust the nipper with the nipper bar block.

Advance the timing of the knot-tying plate.

(Adjustment of the knot-tying notch.)

3. The last back-tack

stitch is poorly tensed.

The nipper has been improperly

adjusted.

Timing of the knot-tying plate is

incorrect.

4. Length of thread

remaining, after thread

trimming, on the wrong

side of the material

varies.

Position of the moving knife is not

correct.

Lifting amount of the button clamp jaw

unit is excessive.

Adjust the position of the moving knife when the

machine completes stop-motion.

(10.5 to 12.5 mm)

Adjust the lifting amount of the button clamp jaw

lever to 8 mm (for コ -shaped tacking and Z-

shaped tacking) or 10 mm (for X-shaped tacking).

Loading...

Loading...