Adjusting the pressing pressure of the

feed

lever

The reversing spring of the feed lever is

strengthened somewhat so that at high speed

sewing, no matter what kind of stitches are

to

be

formed, the lever returns positively to

the original position.

When the stitching pitch is small or when the

machine is to be run by lowering the

r.p.m.,

the pressing pressure of the feed lever can

be

lessened by loosening the adjusting nut

@

of

the accompanying figure.

L

I

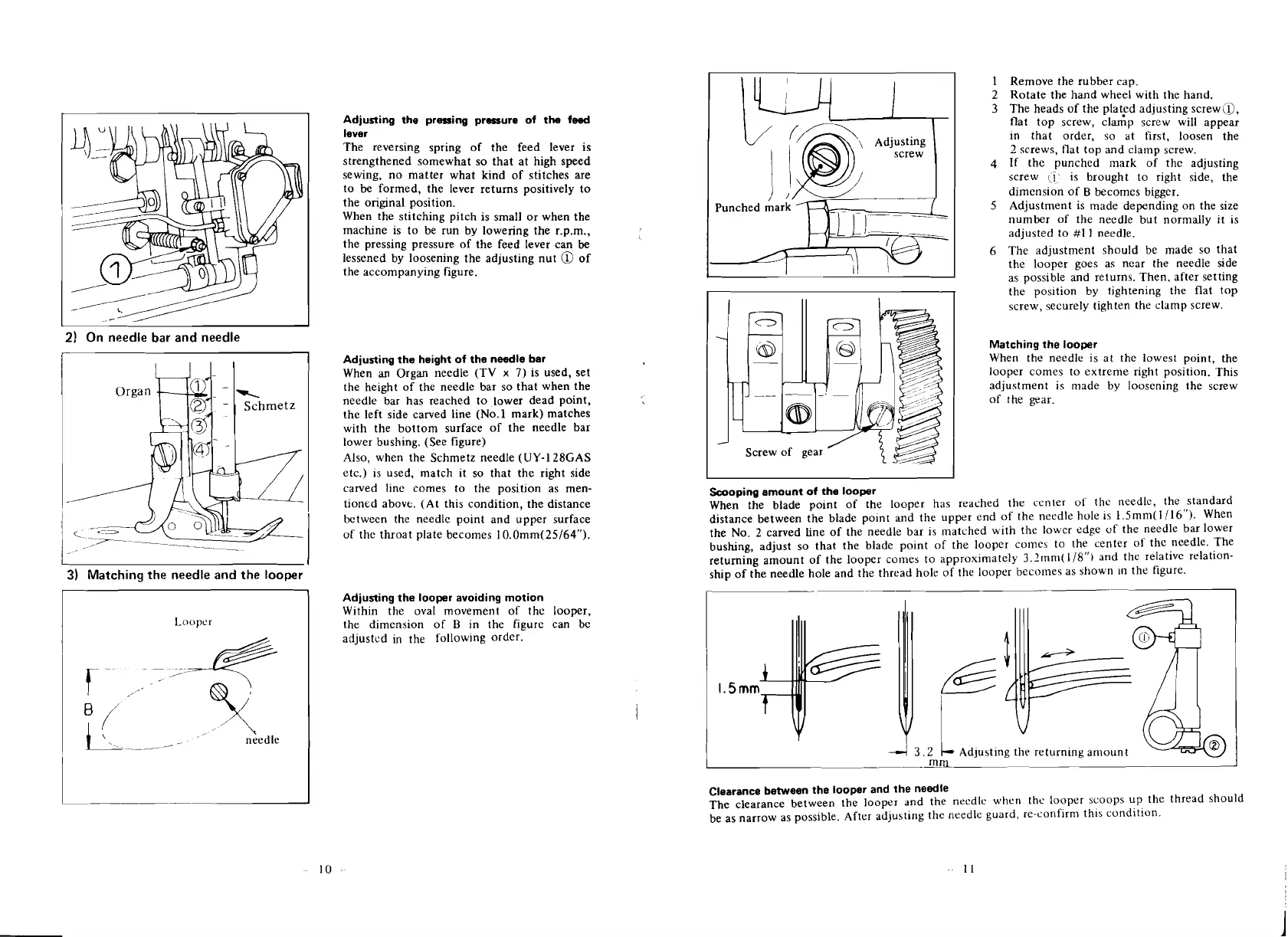

2)

On needle bar and needle

Adjusting the height of the needle bar

When

an

Organ needle

(TV

x

7)

is used, set

the height of the needle bar so that when the

needle bar has reached to lower dead point,

the left side carved line

(No.1 mark) matches

with the bottom surface of the needle bar

lower bushing. (See figure)

Also, when the Schmetz needle (UY-128GAS

etc.)

IS

used, match it so that the right side

carved line comes to the position as men-

tioned above. (At this condition, the distance

bctwecn the needle point and upper surface

of the throat plate becomes

10.0mm(25/64").

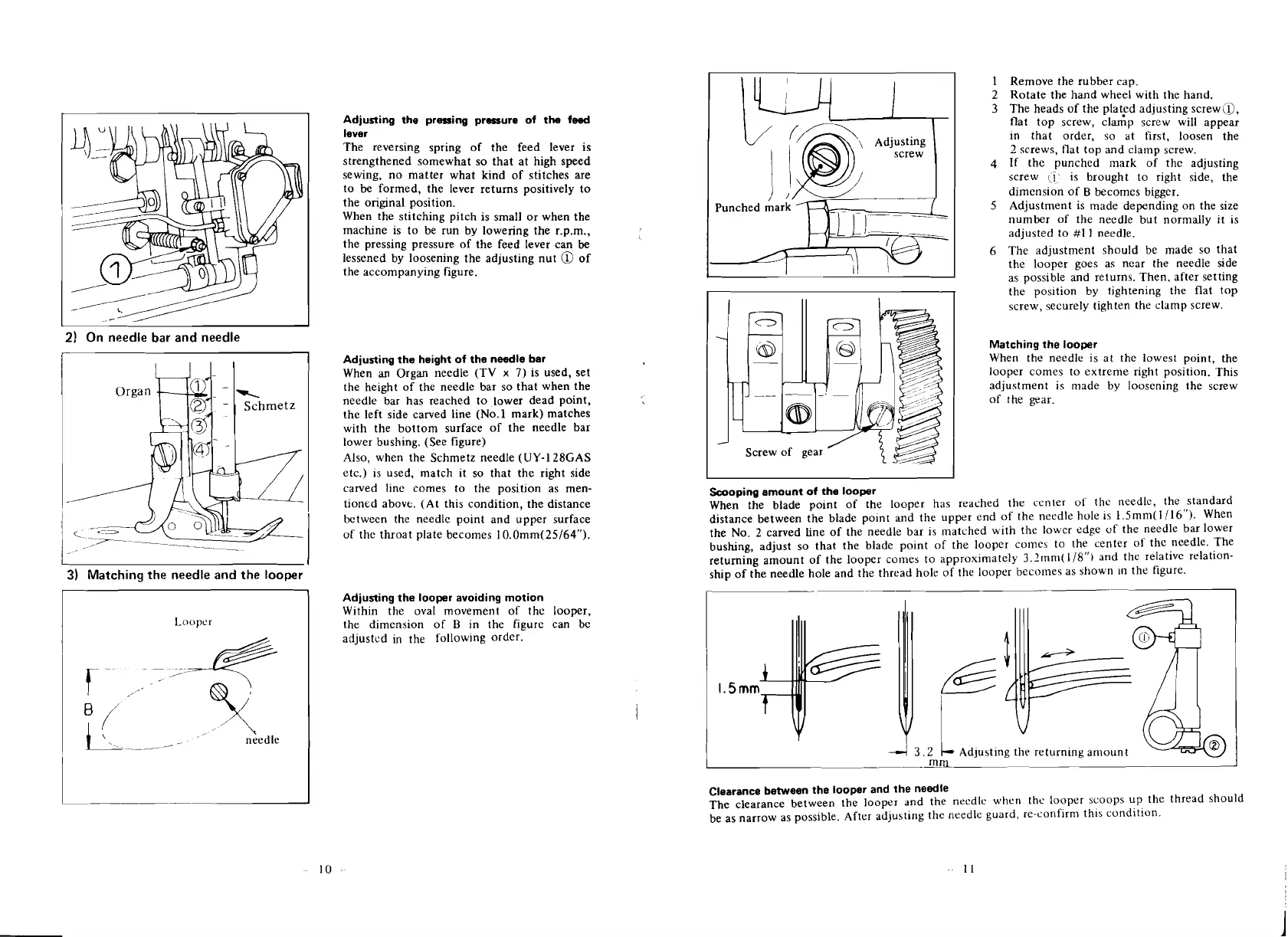

3)

Matching the needle and the looper

Lvopcr

\

needle

Adjusting the looper avoiding motion

Within the oval movement of the looper,

the dimcnsion of

B

in the figure can be

adjustcd

in

the following order.

1

Remove the rubber cap.

2

Rotate the hand wheel with the hand.

3 The heads of the plated adjusting

screw(D,

flat top screw, clGp screw will appear

in that order, so at first, loosen the

2

screws, flat top and clamp screw.

4

If the punched mark of the adjusting

screw

(i'

is brought to right side, the

dimcnsion of

B

becomes bigger.

5

Adjustment is made depending on the size

number of the needle but normally it is

adjusted to

#1 1 needle.

6

The adjustment should be made so that

the looper goes as near the needle side

as possible and returns. Then. after setting

the

pos~tion by tightening the flat top

screw, securely tighten the clamp screw.

Matching the looper

When the needle is at the lowest point, the

looper comes to extreme

right position. This

adjustment is made by loosening the screw

of the gear.

Scooping amount of the looper

When the blade point of the looper has reached the center of the needle, the standard

distance between the blade

polnt and the upper end of the needle hole is 1.5mm(l/l6"). When

the No.

2

carved Line of the needle bar is matched with the lower edge of the needle bar lower

bushing, adjust so that the blade point of the looper

come5 to the center of the needle. The

returning amount of the looper comes to approximately

3.2mrn(1/8") and the relative relation-

ship of the needle hole and the thread hole of the looper becomes as shown

In the figure.

Clearance between the looper and the needle

The clearance between the looper and the needle when the looper scoops up the thread should

be as narrow as possible. After

ad~usting the needle guard, re-conf~rn~ th~s condition.

I

I

Loading...

Loading...