IV.

MAINTENANCE

OF

THE

MACHINE

O As the knife of the machine cuts the cloth, much waste cloth will be produced, so clean the machine at least once a day.

Dust and thread hards are liable to be collected especially in the clearances

of

the

throat

plate, needle guard aMl feed dog, so remove the

throat

plate and clean it thoroughly at least once a week.

0 Inspect the machinehead at least oncea year and operate the machinein perfectly maintainedcondition.

V.

CAUSES

OF

MALFUNCTIONS

AND

CORRECTIVE

MEASURES

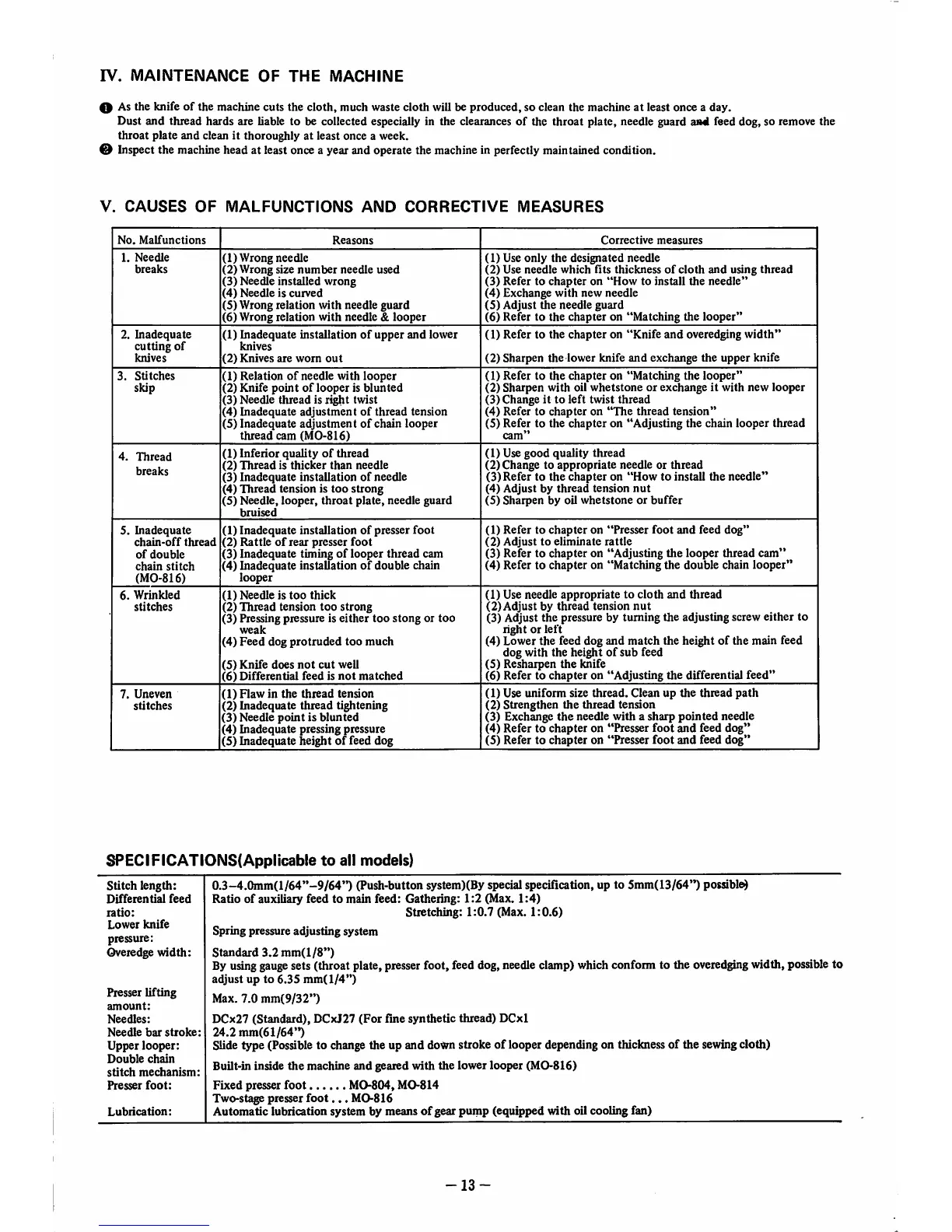

No.

Malfunctions

Reasons

Corrective

measures

1.

Needle

breaks

(1) Wrong needle

(2)

Wrong size

number

needle used

(3)

Needle installed wrong

(4)

Needle

is

curved

(5) Wrong

relation

with

needle

guard

(6) Wrong relation with needle &

looper

(1)

Use

only

the

designated

needle

(2)

Use

needle

which

fits

thickness

of

cloth

and

using

thread

(3) Refer to

chapter

on

"How

to install

the

needle"

(4)

Exchange

with

new

needle

(5)

Adjust

the

needle

guard

(6) Refer to the

chapter

on "Matching the

looper"

2.

Inadequate

cutting

of

knives

(1)

Inadequate

installation

of

upper

and

lower

knives

(2)

Knives

are

worn

out

(1) Refer to the

chapter

on

"Knife

and

overedging

width"

(2) Sharpen the lower knife and exchange the upper knife

3.

Stitches

skip

(1) Relation

of

needle

with

looper

(2) Knife

point

of

looper is blunted

(3) Needle

thread

is

right

twist

(4)

Inadequate

adjustment

of

thread

tension

(5) Inadequate adjustment

of

chain looper

thread

cam

(MO-816)

(1) Refer to

the

chapter

on "Matching the

looper"

(2)

Sharpen

with

oil

whetstone

or

exchange

it

with

new

looper

(3) Change it to left twist thread

(4) Refer to chapter on

"The

thread

tension"

(5) Refer to the chapter on "Adjusting the chain looper thread

cam"

4.

Thread

breaks

(1)

Inferior

quality

of

thread

(2)

Thread

is

thicker

than

needle

(3) Inadequate installation of needle

(4)

Thread

tension is

too

strong

(5)

Needle,

looper,

throat

plate,

needle

guard

bruised

(1) Use

good

quality

thread

(2) Change to

appropriate

needle or

thread

(3) Refer to the chapter on "How to install the needle"

(4) Adjust by

thread

tension

nut

(5) Sharpen by oU whetstone or

buffer

5.

Inadequate

chain-off

thread

of

double

chain

stitch

(MO-816)

(1) Inadequate installation of presser

foot

(2)

Rattle

of

rear

presser

foot

(3) Inadequate timing

of

looper thread cam

(4) Inadequate installation

of

double chain

looper

(1) Refer to

chapter

on "Presser

foot

and

feed

dog"

(2)

Adjust

to

eliminate

rattle

(3) Refer to chapter on "Adjusting the looper thread

cam"

(4) Refer to chapter on "Matching the double chain

looper"

6.

Wrinkled

stitches

(1)

Needle is

too

thick

(2)

Thread

tension

too

strong

(3)

Pressing pressure is

either

too

stong

or

too

weak

(4)

Feed

dog

protruded

too

much

(5)

Knife

does

not

cut

well

(6)

Differential

feed

is

not

matched

(1) Use needle

appropriate

to

cloth

and

thread

(2)

Adjust

by

thread

tension

nut

(3) Adjust the pressure by turning the adjusting screw either to

right

or

left

(4) Lower the feed dog and match the height of the main feed

dog with the height

of

sub feed

(5) Resharpen

the

knife

(6) Refer to chapter on "Adjusting the differential feed"

7.

Uneven

stitches

(1)

Flaw

in

the

thread

tension

(2) Inadequate thread tightening

(3) Needle

point

is

blunted

(4)

Inadequate

pressing pressure

(5) Inadequate height of feed dog

(1) Use uniform size

thread.

Clean up

the

thread

path

(2) Strengthen the thread tension

(3) Exchange the needle with a sharp pointed needle

(4) Refer to chapter on "Presser foot and feed dog"

(5) Refer to chapter on "Presser

foot

and

feed

dog"

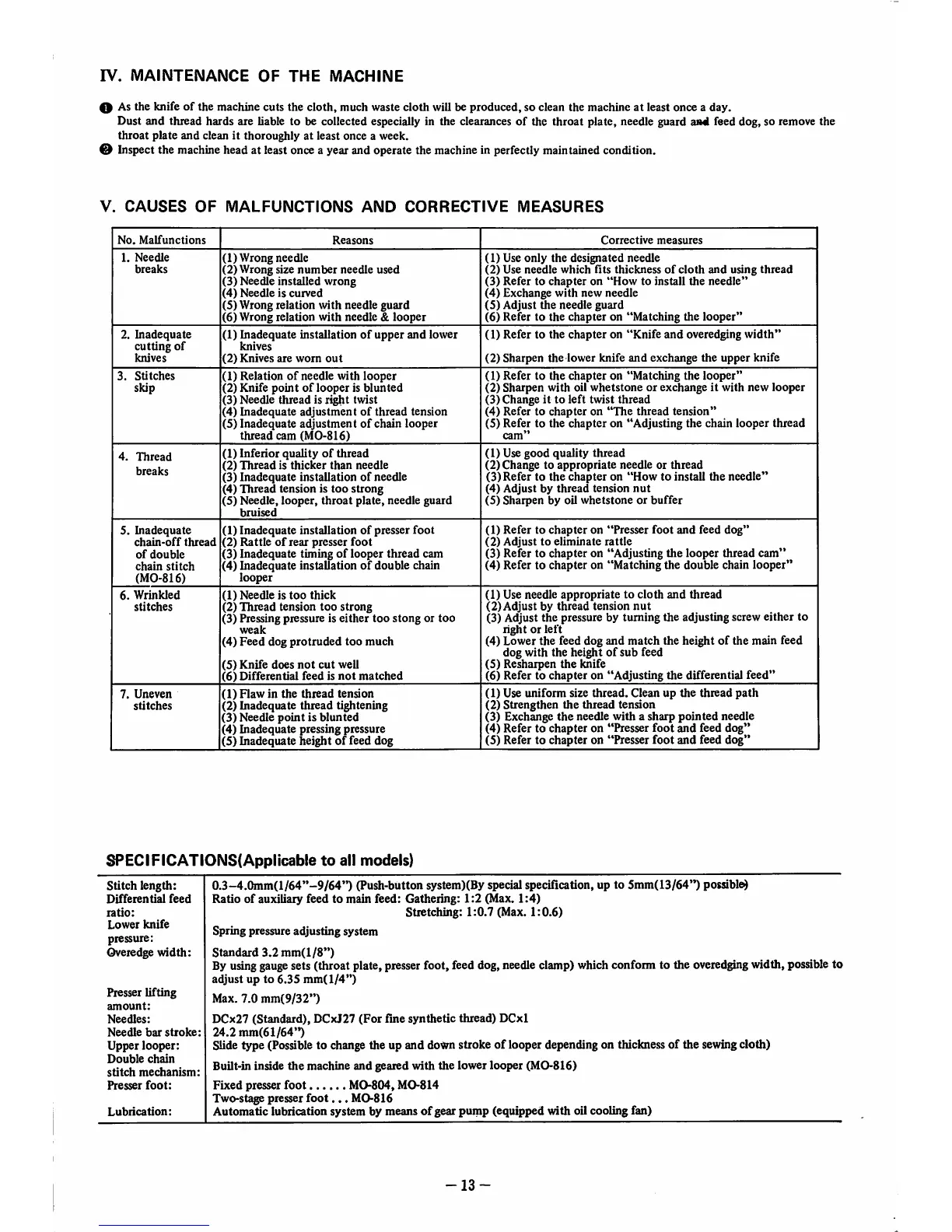

SPECIFICATIONS(Applicable

to

all models)

Stitch length:

Differential

feed

ratio:

Lower

knife

pressure:

Overedge

width:

Presser lifting

amount:

Needles:

Needle

bar

stroke:

Upper looper:

Double

chain

stitch

mechanism:

Presser

foot:

Lubrication:

0.3-4.0mm(l/64"-9/64")

(Push-button system)(By special specification, up to 5mm(13/64") possibly

Ratio

of

auxiliary feed to main feed: Gathering:

1:2

(Max.

1:4)

Stretching: 1:0.7 (Max.

1:0.6)

Spring pressure adjusting system

Standard

3.2

mm(l/8")

Byusing

gauge

sets (throat plate, presserfoot, feed dog,needleclamp)whichconform to the

overedging

width, possibleto

adjust up to 6.35

mm(l/4")

Max.

7.0

mm(9/32")

DCx27

(Standard),

DCxJ27

(For

fine

synthetic

thread)

DCxl

24.2

mm(61/64'*)

Slide type (Possible to change the up and down stroke

of

looper depending on thickness of the sewing cloth)

Built-in inside the machine and geared with the lower looper (MO-816)

Fixed

presser

foot

MO-804, MO-814

Two-stage presser

foot...

MO-816

Automatic lubrication system by means

of

gear pump (equipped with oil cooling fan)

-13-

Loading...

Loading...