– 1 –

1. Carry the sewing machine with two persons.

(Caution) Do not hold the main shaft.

2.

Do not put protruding articles such as the screwdriver and the like at

the location where the sewing machine is placed.

3. Place the sewing machine on the table aligning the mounting holes

in the former with those in the latter.

4. Pass hexagonal head bolts

❶

and washers

❷

through four mounting

holes in the sewing machine and x them with washers

❷

and nuts

❸

from the underside of the table.

WARNING :

To avoid possible personal injury due to abrupt start of the machine, turn off the power to the machine and check to be sure

that the motor has totally stopped rotating in prior.

❶

❷

❷

❸

1. INSTALLING THE MACHINE

SPECIFICATIONS

Stitch system TSN-421: 1-needle, needle feed, long cylinder

bed, lockstitch machine for extra heavy-

weight materials wuth a semi-rotary

large-capacity shuttle

Thread take-up lever Cam-type thread take-up lever

Needle bar stroke 56 mm

Needle to be used Schmetz 794

TSC-441: 1-needle, unison feed, long cylinder

bed, lockstitch machine for extra heavy-

weight materials wuth a semi-rotary

large-capacity shuttle

Needle system Nm 130 to Nm 280 (standard: Nm 230)

Thread #00 to #8

Stitch adjusting method Lever nut type

Usage Pouches, bags, shoes, bag handles, safety belts, etc. Lubrication method Hand oiling

Sewing speed Max. 800 sti/min Motor to be used 3-phase/single phase 400W clutch motor (4P)

Stitch length Max. 11 mm Oil to be used JUKI New defrix oil No.1

Lift of presser foot Hand lifter 12 mm, Knee lifter 20 mm

Noise - Equivalent continuous emission sound pressure level (L

pA

) at the workstation:

A-weighted value of 77.0 dB; (Includes K

pA

= 2.5 dB); according to ISO 10821- C.6.2 -ISO 11204 GR2 at 800 sti/min.

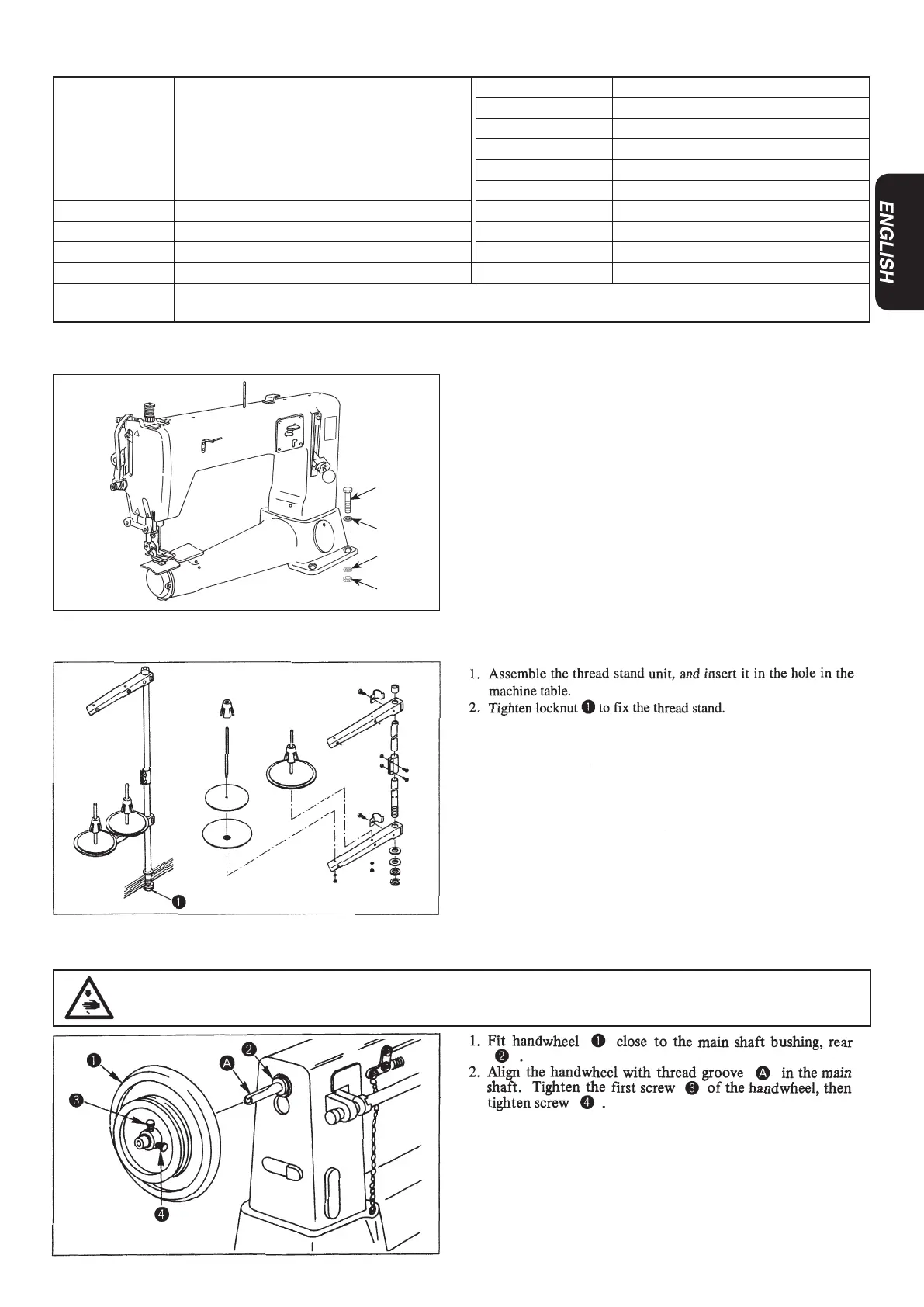

2. INSTALLING THE THREAD STAND

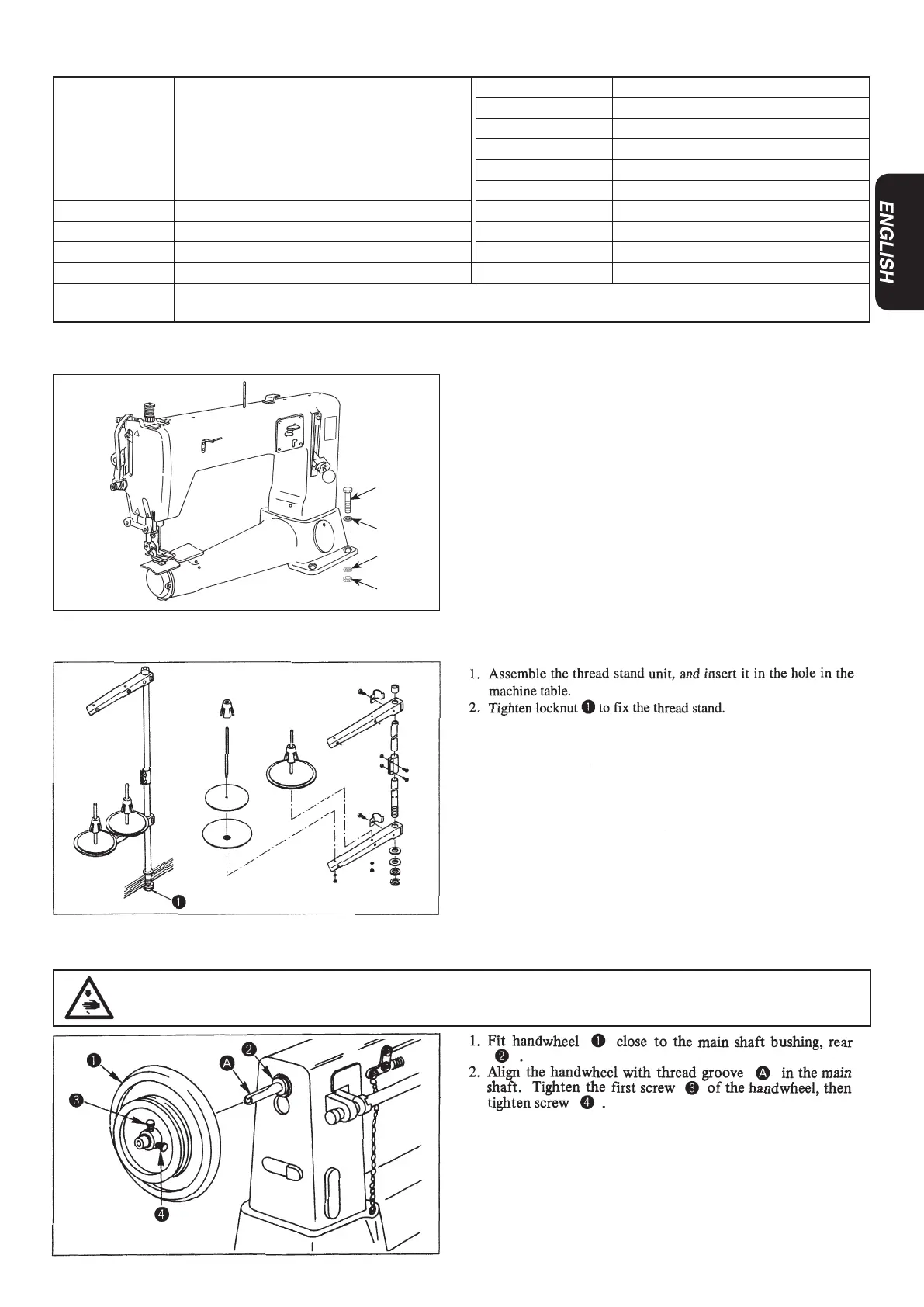

3. INSTALLING THE HANDWHEEL

Loading...

Loading...