– 1 –

SPECIFICATIONS

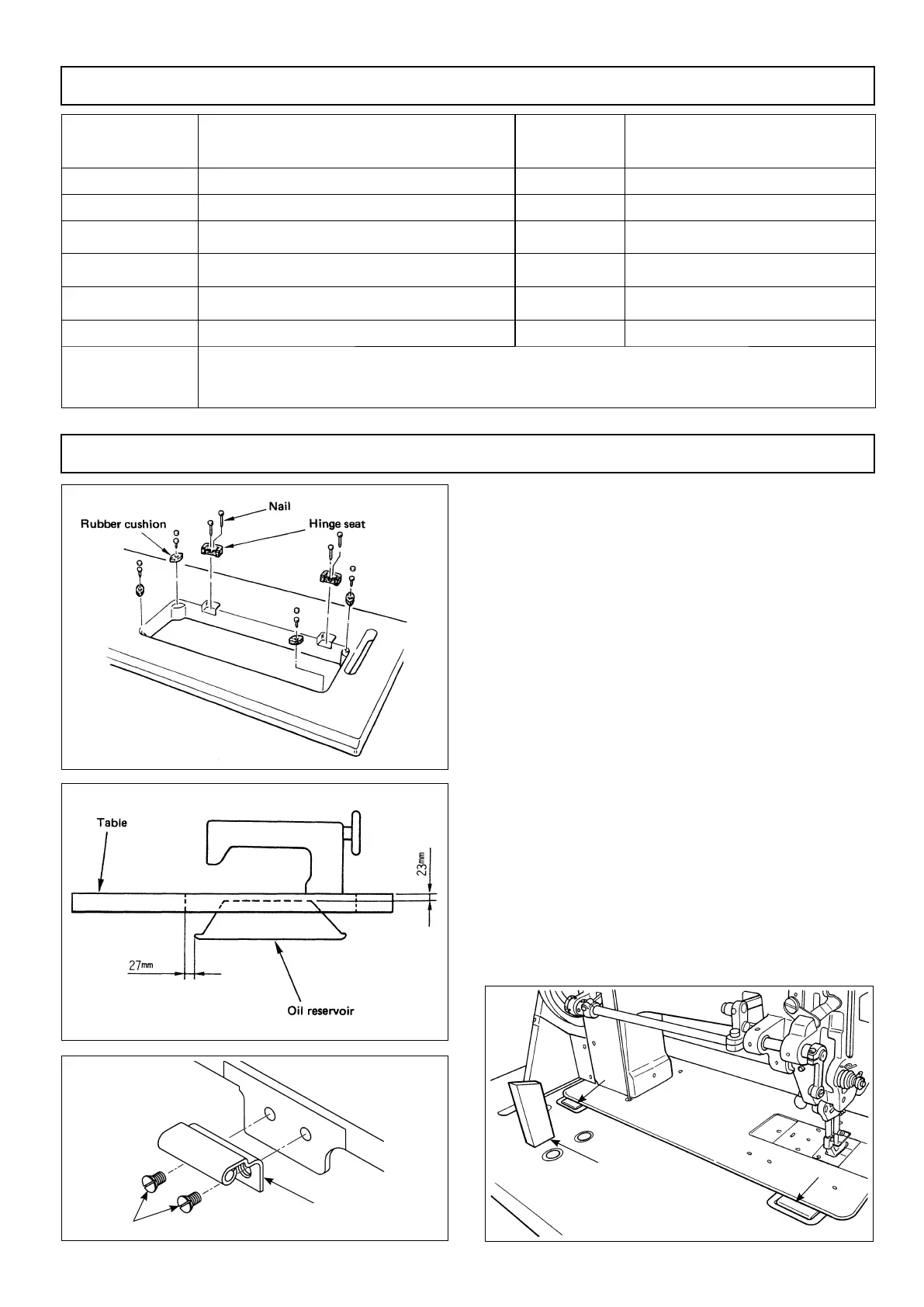

1. INSTALLING THE MACHINE

1) When carrying the sewing machine, be sure to carry by

two people.

(Caution) Do not hold the pulley.

2) Do not place a protruding object, such as a screw driver, at

a place where the sewing machine is to be installed.

3) Fix the hinge seats and the support rubbers supplied with

the machine on the table using nails.

4) Fix oil pan supplied with the machine on the table in 6

places with wood screws.

5) Install hinge arms

❶

to the front and rear (at one location

each) of the sewing machine head with screws

❷

.

6) Place the machine head down on the machine head

support rubbers at four corners by engaging hinge arm

❶

with the hinge seat of the table.

7) Install head support bar

❸

fi rmly on the table by inserting it

into the table hole until it will go any further.

Type of sewing

machine head

1-needle,unison-feed lockstitch machine with

semi-rotary large capacity shuttle for extra heavy-

weight materials

Needle SCHMETZ 794

Usage Tents, bags, shoes, bag handles, safety belts, etc. Needle system Nm 130

〜

Nm 280 (Standard Nm 230)

Sewing speed Max. 800 sti/min Thread #00

〜

#8

Stitch length Max. 15 mm

Stitch adjusting

method

Lever nut type

Lift of presser foot Hand lifter : 12 mm Knee lifter : 20 mm

Lubrication

method

Hand oiling

Thread take-up

lever

Cam-type thread take-up lever

Motor to be

used

400W clutch motor (4P)

Needle bar stroke 56 mm Lubricating oil JUKI New Defrix Oil No. 1

Noise

- Equivalent continuous emission sound pressure level (L

pA

) at the workstation :

A-weighted value of 76.5 dB; (Includes K

pA

= 2.5 dB); according to ISO 10821- C.6.2 -ISO 11204 GR2 at 800

sti/min.

❶

❷

❸

❶

❶