Juniper Networks SSG 5 and SSG 20 Security Policy

Physical Security Policy

Before carrying out any steps to deploy a Juniper Networks security appliance, the end-user must

verify the security of the product with the following observations:

1. Confirm that the product received matches the version that is validated as FIPS 140-2

compliant.

2. The outside packaging does not show damage or evidence that is has been opened. If

the cardboard shows damage that would allow the device to be removed or exchanged,

this may be evidence of tampering.

3. Each box is packaged with custom tape to indicate that the device was packaged by

Juniper Networks or an authorized manufacturer. The tape is unique, with the words

Juniper Networks printed repeatedly along the tape. If the tape is not present, the device

may have been tampered with.

4. The internal packaging does not show damage or evidence of tampering. The plastic

bag should not have a large hole and the label that seals the plastic bag should not be

detached or missing. If the bag or seal are damaged in any way, the device may have

been tampered with.

The security appliance is contained within a metal production-grade enclosure that is opaque to visible

spectrum radiation. The enclosure includes a removable cover that must be protected by a tamper-

evident seal.

The Cryptographic Officer is responsible for securing and having control at all times of any unused

seals and the direct control and observation of any changes to the module such as reconfigurations

where the tamper evident seals or security appliances are removed or installed to ensure the security

of the module is maintained during such changes and the module is returned to a FIPS Approved

state.

Tamper seals are applied in the same fashion regardless of the part number of the device.

Inspection/Testing of Physical Security Mechanisms

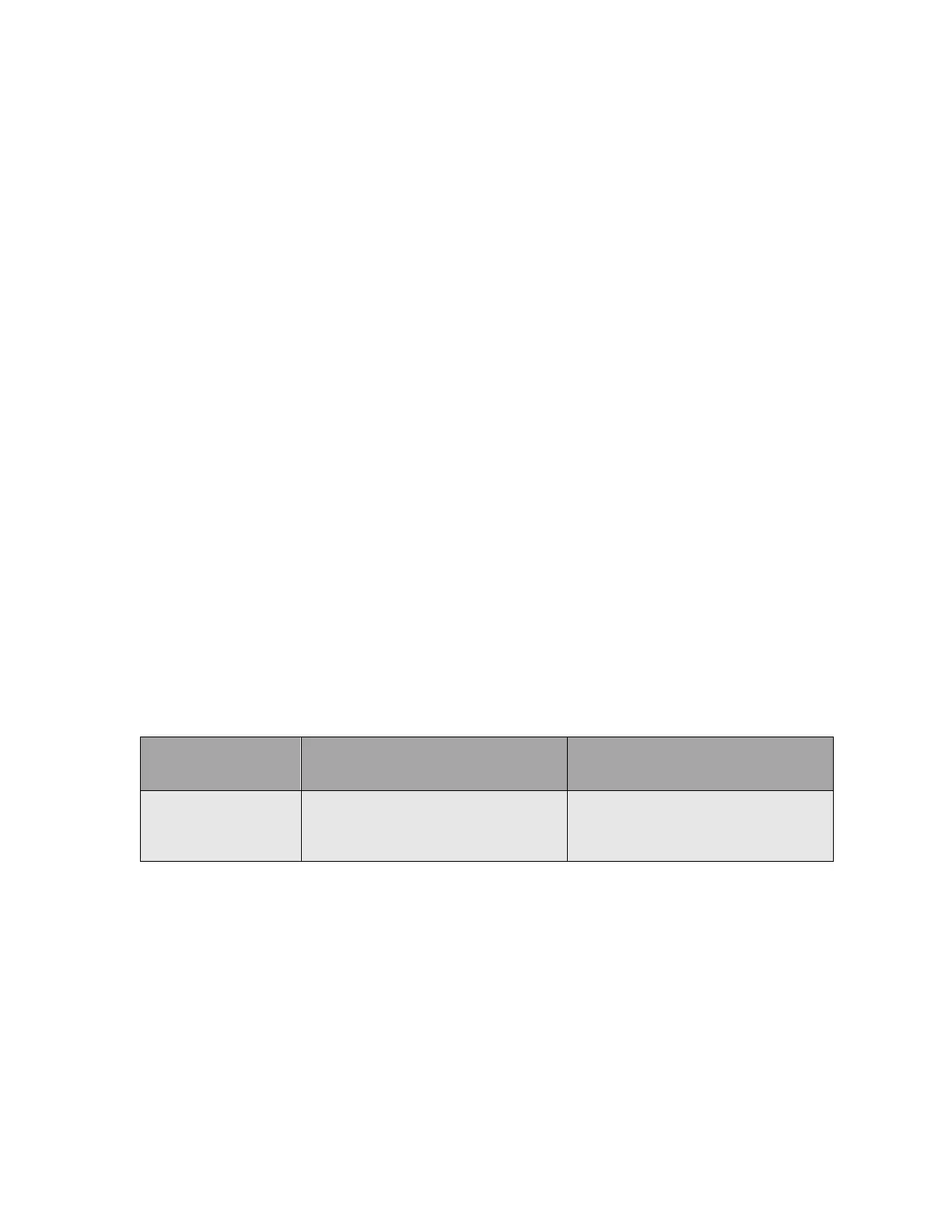

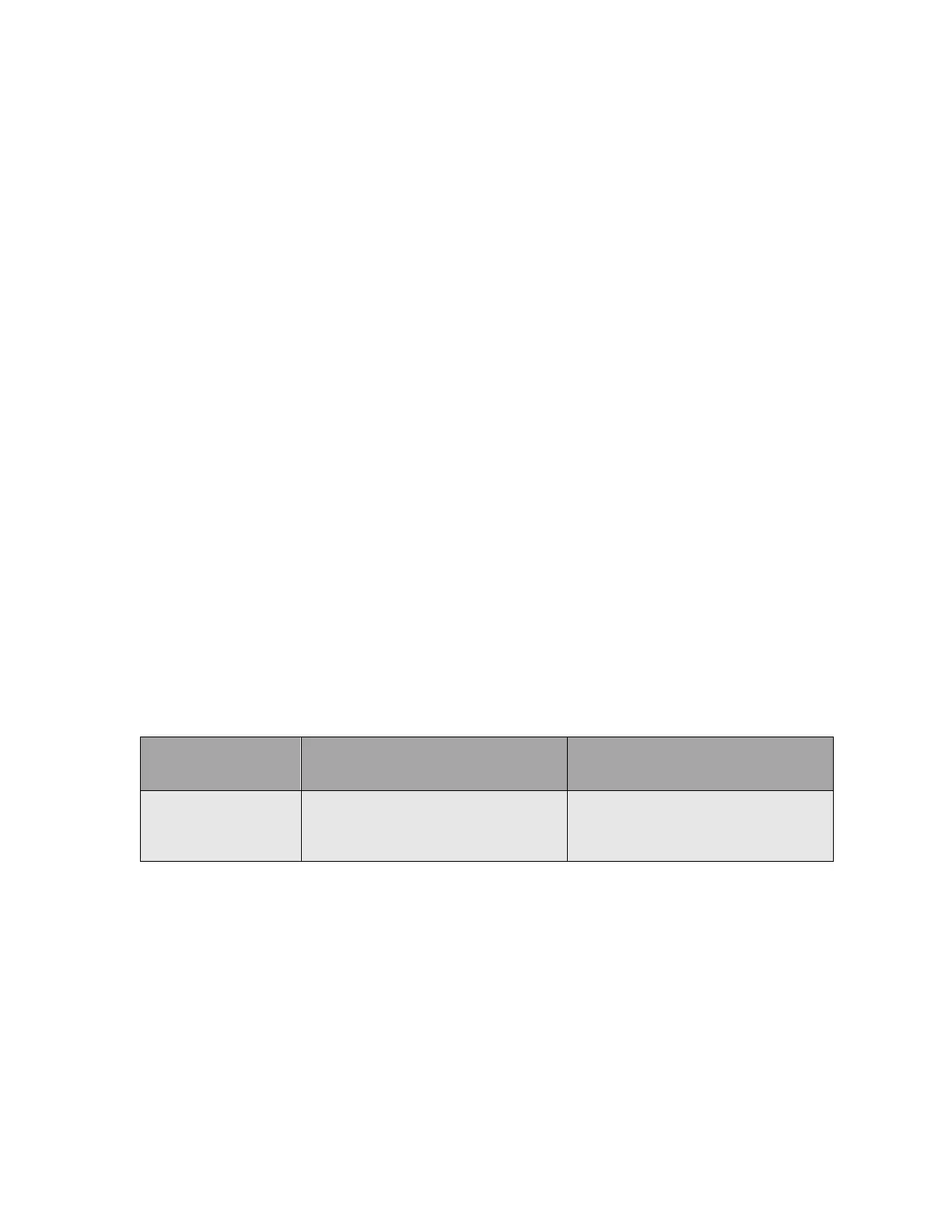

Physical Security

Mechanisms

Recommended Frequency of

Inspection/Test

Inspection/Test Guidance Details

Tamper labels,

opaque metal

enclosure.

Upon receipt of the module and per

security policy by the Cryptographic

Officer.

Labels should be free of any tamper

evidence.

Seals are available for order via part number JNPR-FIPS-TAMPER-LBLS. If a seal is missing or

damaged, the device may have been tampered with. Tamper-evident seals should be applied as

described below.

For all seal applications, the Cryptographic Officer should observe the following instructions.

• Handle the seals with care. Do not touch the adhesive side.

• All surfaces to which the seals are to be applied must be prepared by using an alcohol wipe to

ensure that all surfaces are clean and clear of any residue.

• Apply with firm pressure across the seal to ensure adhesion. Allow at least 1 hour for the

adhesive to cure.

Loading...

Loading...